Heavy oil hydrogenation catalyst and preparation method thereof

A heavy oil hydrogenation and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of catalyst fragmentation and deactivation, and unfavorable mass transfer of macromolecules , Poor spatial coherence and other issues, to achieve the effect of increasing the density, improving the mechanical strength and maintaining the integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

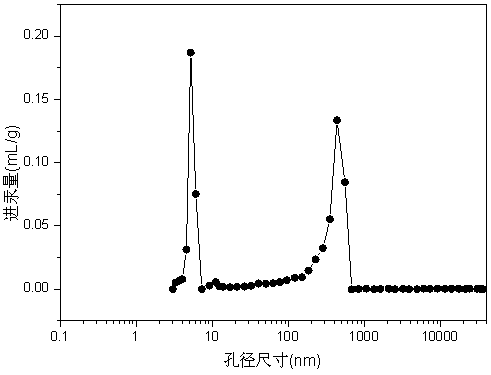

Embodiment 1

[0038] At room temperature (20°C), mix water, absolute ethanol, aluminum chloride, polyethylene glycol, and formamide evenly, and then add pyridine. The contents of each component of the mixture are by weight: water 23%, ethanol 22% , aluminum chloride 20%, polyethylene glycol (viscosity average molecular weight 1 million) 0.3%, formamide 1%, pyridine 33.7%. After mixing evenly, the obtained gel is aged at 45°C for 48 hours, and then soaked in a mixture of ethanol and water for 48 hours. After soaking and removing the liquid phase, dry it at 40°C until the product no longer occurs. Visible weight loss. Then it was calcined at 550°C for 7 hours, and then cooled to room temperature to obtain the macroporous alumina. The total porosity is 81%, and the pores have a double pore distribution. Among them, the macropores are evenly distributed, the average pore size of the macropores is 400nm, and the macropore porosity accounts for 60%; the mesopore diameter is 4~6nm, and the mesopo...

Embodiment 2

[0042] At room temperature (20°C), mix water, absolute ethanol, aluminum chloride, polyethylene glycol, and formamide evenly, and then add pyridine. The contents of each component of the mixture are by weight: water 31%, ethanol 29% , aluminum chloride 16%, polyethylene glycol (viscosity average molecular weight 2 million) 0.5%, formamide 3.5%, pyridine 20%. After mixing evenly, the obtained gel was aged at 60°C for 24 hours, and then soaked in ethanol for 48 hours. After soaking and removing the liquid phase, it was dried at 50°C until the product no longer lost weight. Then bake at 650° C. for 5 hours, and then cool to room temperature to obtain the macroporous alumina of the present invention. The total porosity is 75%, and the pores have a double pore distribution. Among them, the macropores are evenly distributed. The average pore size of the macropores is 207nm, and the macropore porosity accounts for 43%. The mesopore diameter is 9~12nm, and the mesopore porosity accoun...

Embodiment 3

[0046] At room temperature (20°C), mix water, absolute ethanol, aluminum sulfate, polyethylene glycol, and N,N-dimethylformamide evenly, and then add pyridine. The contents of each component of the mixture are, by weight, water 48%, ethanol 38%, aluminum chloride 10%, polyethylene glycol (viscosity average molecular weight 300,000) 0.78%, N,N-dimethylformamide 3.22%, pyridine 10%. After mixing evenly, the obtained gel product is aged at 80°C for 24 hours, and then soaked in ethanol for 48 hours. After soaking and removing the liquid phase, dry it at 50°C until the product no longer loses weight . Then calcined at 850°C for 5 hours, and then cooled to room temperature to obtain macroporous alumina. The total porosity is 67%, and the pores have a double pore distribution. Among them, the macropores are evenly distributed. The average pore size of the macropores is 709nm, and the macropore porosity accounts for 43%. The mesopore diameter is 14~20nm, and the mesopore porosity acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com