Control valve and centrifugal micro-fluidic chip

A microfluidic chip and control valve technology, applied in fluid controllers, laboratory utensils, laboratory containers, etc., can solve problems such as the influence of the reagent system, exceeding the processing limit, and difficulty in precise control, without complex processing. , easy to use, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

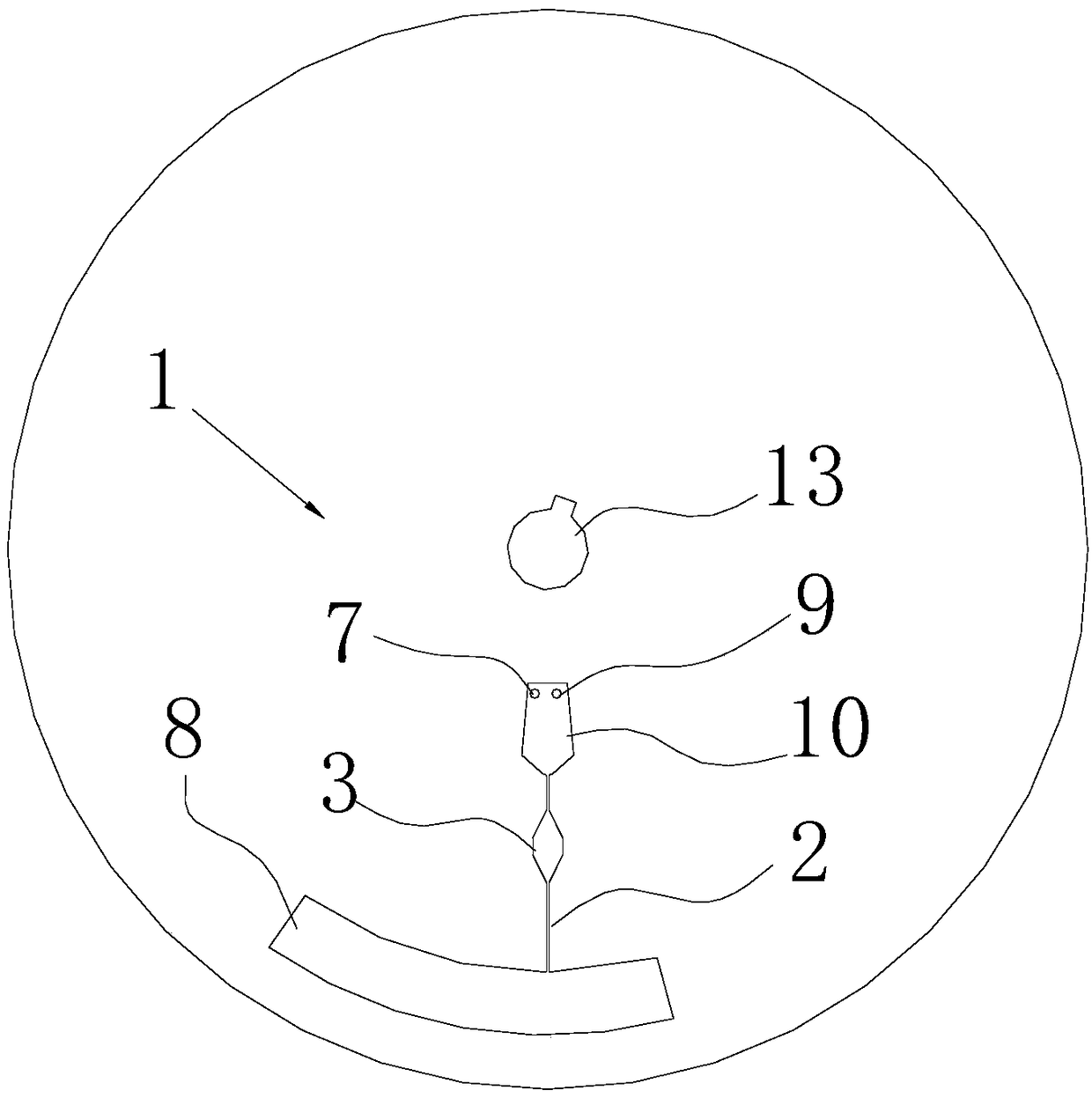

[0049] Such as figure 1 As shown, the present invention provides a control valve, which is arranged on the microfluidic channel 2 of the microfluidic chip. The microfluidic chip includes a chip body 1. As an improvement of the present invention, the control valve includes a valve cavity 3, a reversible water absorption mechanism 4. The reversible water absorption mechanism 4 is set in the valve cavity 3 .

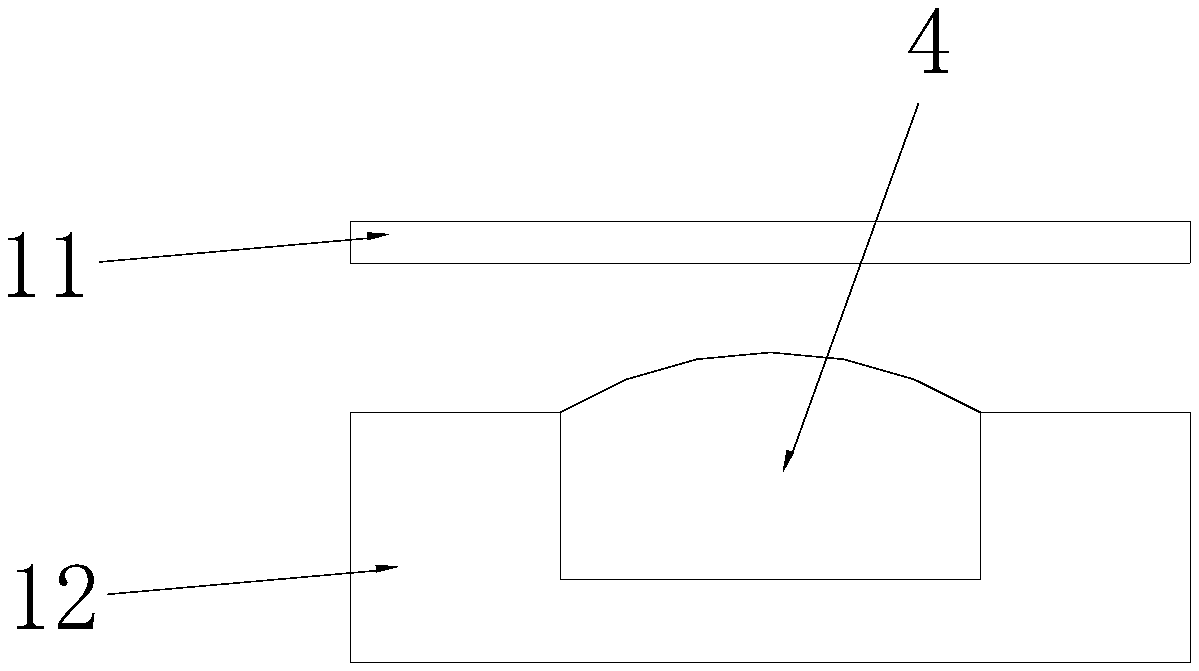

[0050] As a further improvement of the present invention, the reversible water absorption mechanism 4 is packaged in an anti-deformation packaging film (not shown in the figure). The reversible water-absorbing mechanism 4 is one or more of sponge, foam, and water-absorbing fibers. The anti-deformation packaging film is gauze. As shown in FIG. 2 , the chip body 1 includes a chip upper plate 11 and a chip lower plate 12 , and the microfluidic channel 2 and the valve cavity 3 are arranged between the chip upper plate 11 and the chip lower plate 12 .

[0051] The present inv...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is:

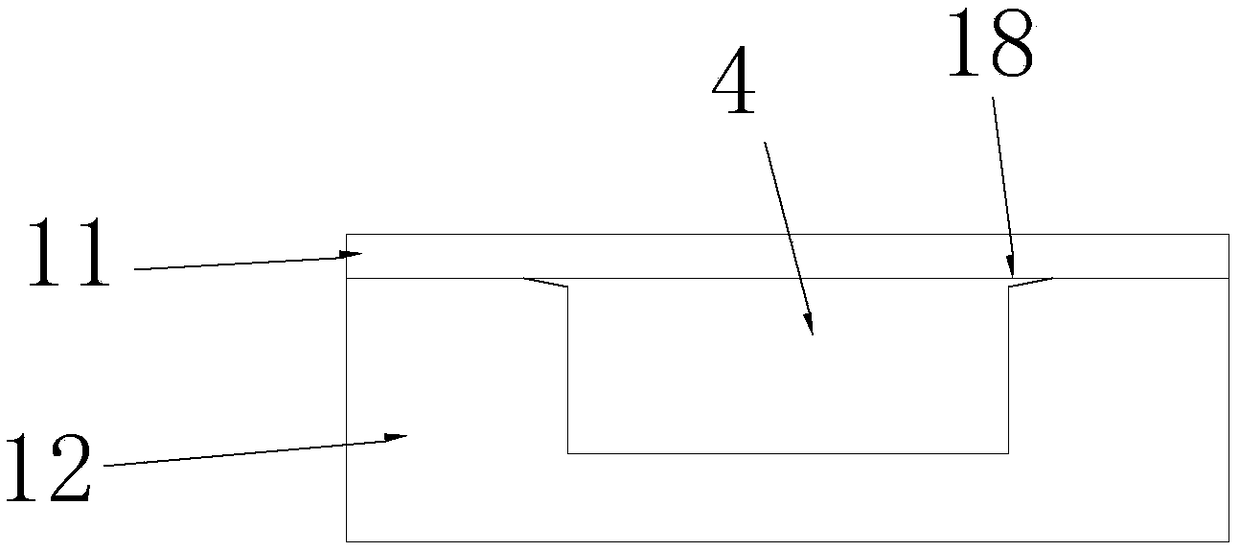

[0061] Such as image 3 As shown, the chip upper board 11 and the chip lower board 12 are provided with a sealing mechanism, and the sealing mechanism is located outside the edge of the valve cavity 3 .

[0062] The sealing mechanism includes matching sealing bosses 5 and sealing grooves 6 ; the sealing bosses 5 are arranged on the chip upper board 11 , and the sealing grooves 6 are arranged on the chip lower board 12 . It is worth noting that the sealing boss 5 can also be arranged on the chip lower board 12 , and the sealing groove 6 is arranged on the chip upper board 11 .

[0063] The cross-sectional shape of the sealing boss 5 is trapezoidal, and the cross-sectional shape of the sealing groove 6 is trapezoidal or rectangular.

[0064] When no sealing mechanism is provided between the upper chip board 11 and the lower chip board 12, as Figure 2a and 2b As shown, when the reversible water-absorbing me...

Embodiment 3

[0067] This embodiment takes the cleaning of magnetic beads in the chemiluminescence reaction process as an example. The chemiluminescence kit generally requires cleaning of the magnetic beads 2-3 times. Through the device of the present invention, after adding the cleaning solution once, the cleaning solution can be quantitatively released successively to realize The process of magnetic bead washing.

[0068] Considering the reagent ratio of chemiluminescence and the characteristics of the centrifugal microfluidic chip, in this embodiment, a total of 60 μL of cleaning solution was released three times.

[0069] Such as Figure 5 As shown, the structure of the centrifugal microfluidic chip used in this embodiment is the same as that of the centrifugal microfluidic chip in the first or second embodiment, and the reaction chamber is the cleaning pool 80 .

[0070] The reversible water absorption mechanism selects the highly water-absorbing and hygroscopic fiber "Hygra" porous m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com