Tungsten inert gas welding method of austenitic heat-resistant steel

A technology of austenitic heat-resistant steel and tungsten argon arc welding, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc. The process is not clear and other problems, to achieve the effect of improving the welding work efficiency, inhibiting the occurrence of hot cracks, and strictly and reasonably controlling the parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

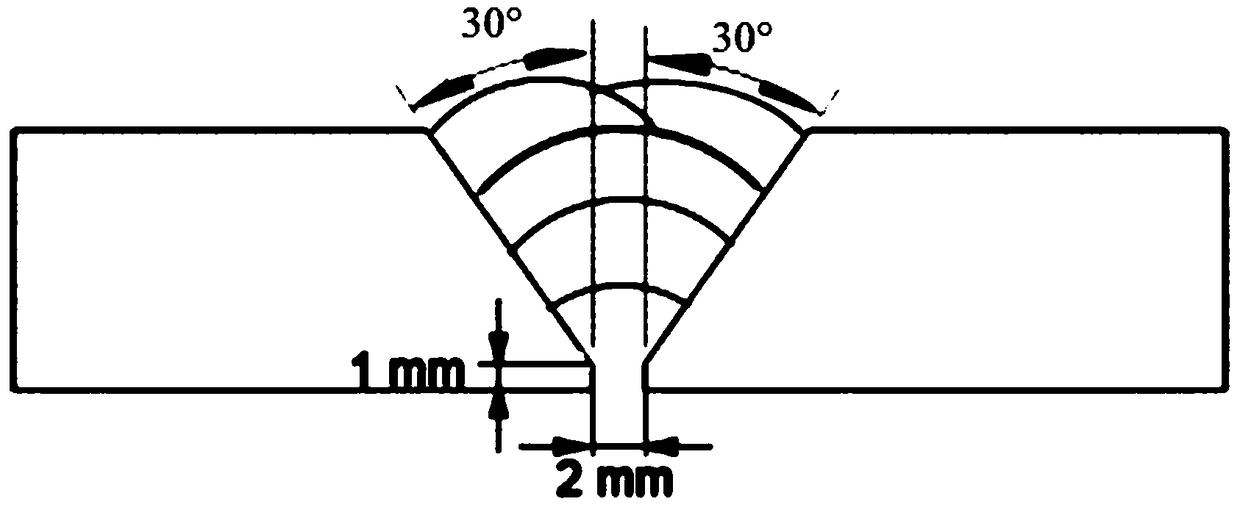

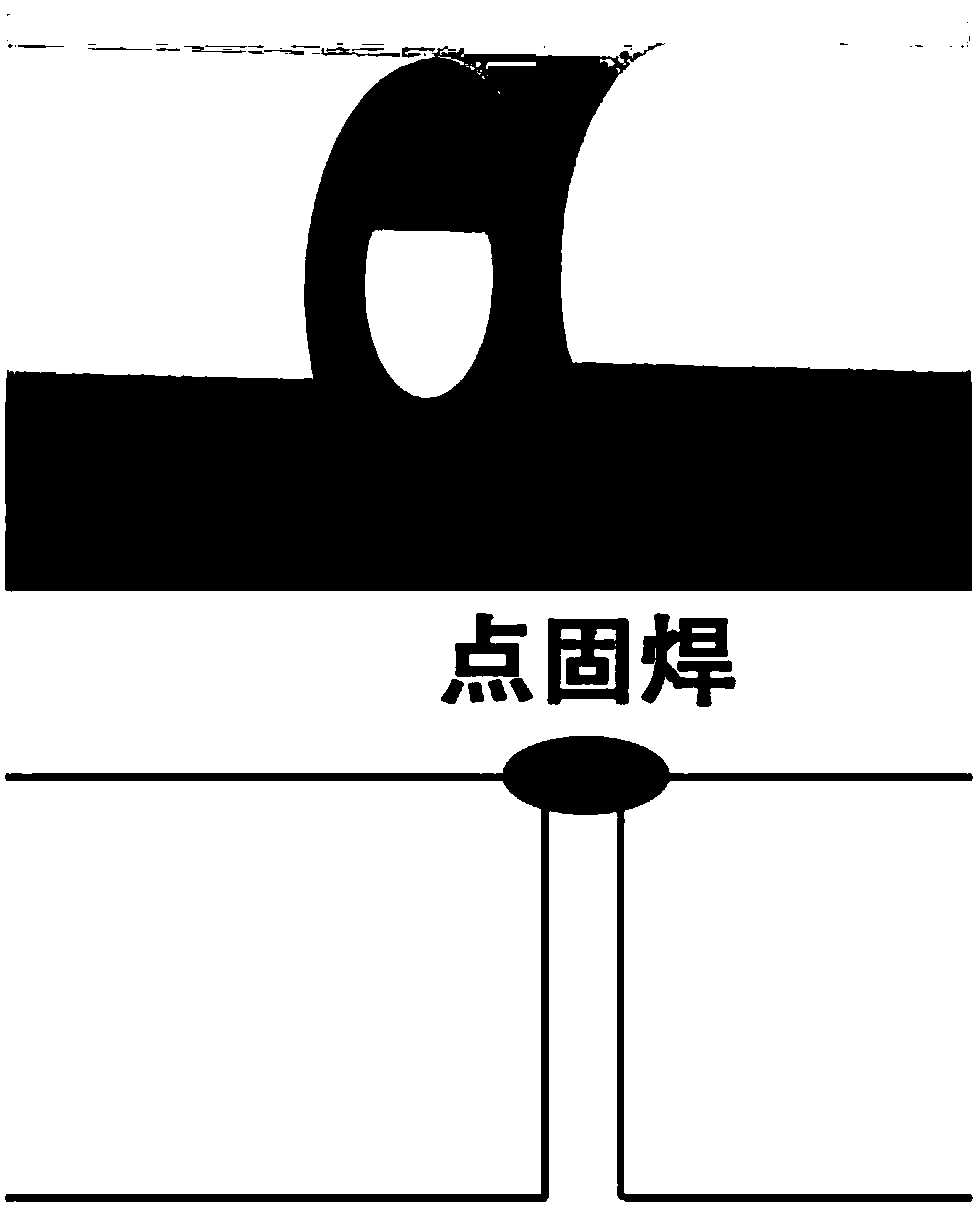

[0024] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims. The present invention is described in detail below through specific examples. The present invention comprises the following steps:

[0025] Step 1, base metal material selection: 22Cr25NiWCoCu (UNSS31035) seamless steel pipe is selected as the austenitic heat-resistant steel, the outer diameter of the pipe is φ53.8mm, and the wall thickness is 8.9mm. The pipe specification is not limited to this. Selection of welding consumables: use domestically-made argon tungsten arc welding solid wire with a diameter of Φ2.4mm, and the diameter of the wire is not limited to this.

[0026] The welding wire is a product of Kunshan Jingqun Welding Material Technology Co., Ltd., the application number is 2017114261509, and the application date is December 25, 2017. The welding wire is an electric welding rod, which is composed of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com