Control method of power transmission system of novel gas-electric hybrid washing and sweeping vehicle

A power transmission system and control method technology, applied in the field of sanitation machinery, can solve problems such as difficult implementation, low load rate of the main engine, and poor emission performance, so as to improve power and fuel economy, reduce fuel consumption and emissions, and reduce installed capacity. The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

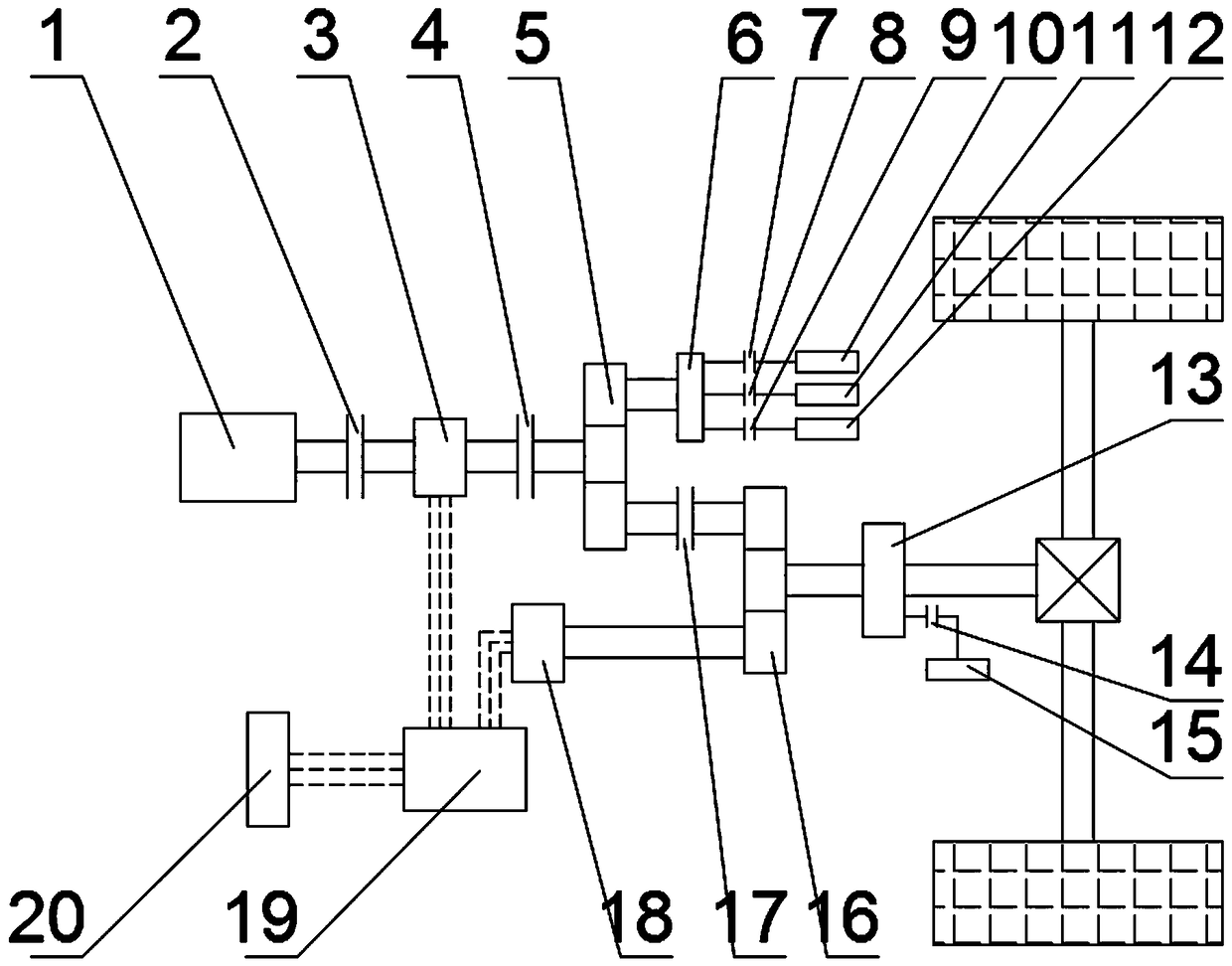

Embodiment 1

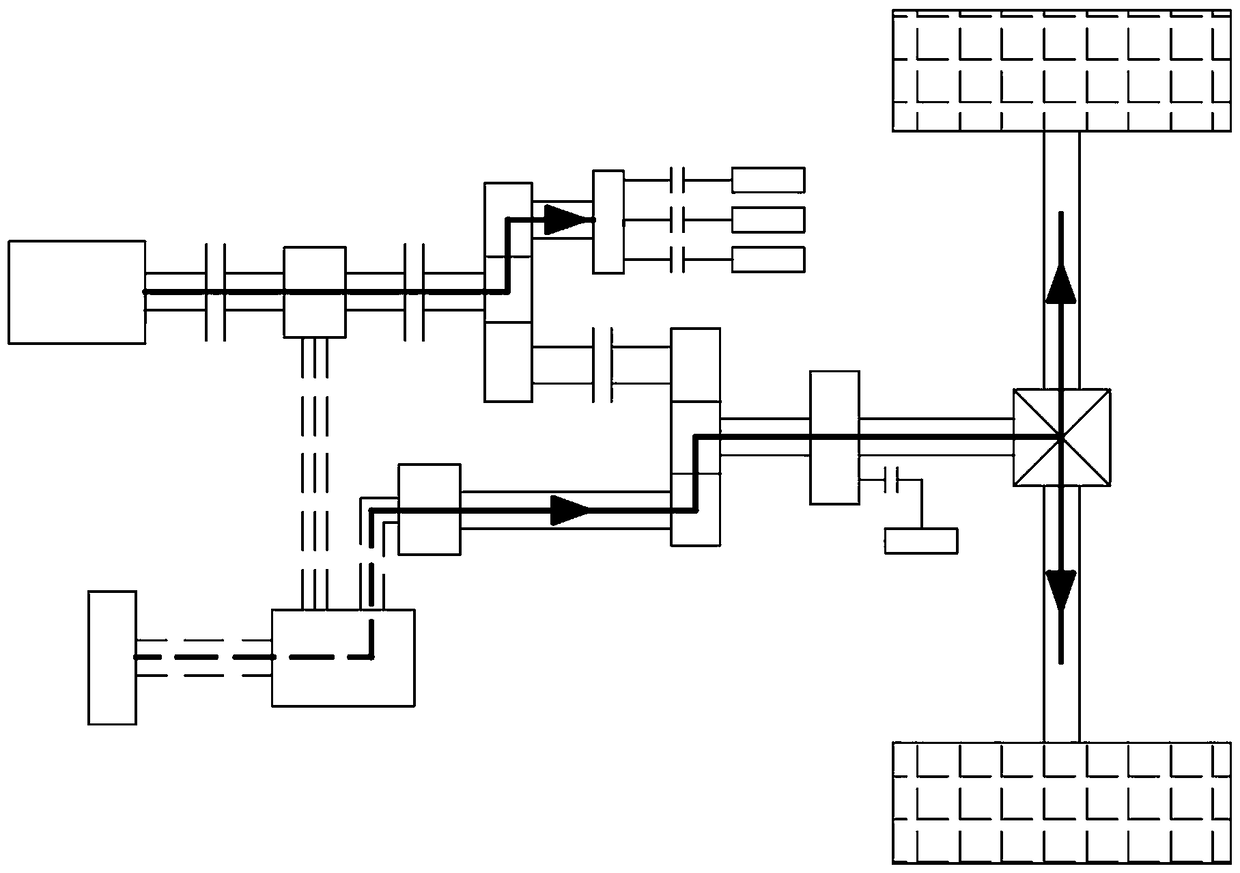

[0088] figure 2 It is the transmission route diagram of the present invention under the operation mode of hybrid electric cleaning with sufficient electric power: the traveling device route is as follows: main motor 18→torque coupling 16→transmission 13→transmission shaft→differential device→wheels; cleaning operation route Engine 1→clutch I2→ISG motor 3→clutch II4→power splitter 5→power take-off 6→working device. In this mode, the low-pressure water pump clutch 14 is closed, the high-pressure water pump clutch 8, the fan clutch 9 and the hydraulic pump clutch 7 are connected, so that the high-pressure water pump 11, the fan 12 and the hydraulic pump 10 are in the working state, the clutch I2 and the clutch II4 are combined, and the clutch III17 Disconnected, the power splitting device and the torque coupling device do not produce a mechanical connection, that is, the main motor 18 is used to drive the vehicle, providing a driving speed of about 7-12km / h, and the satisfied en...

Embodiment 2

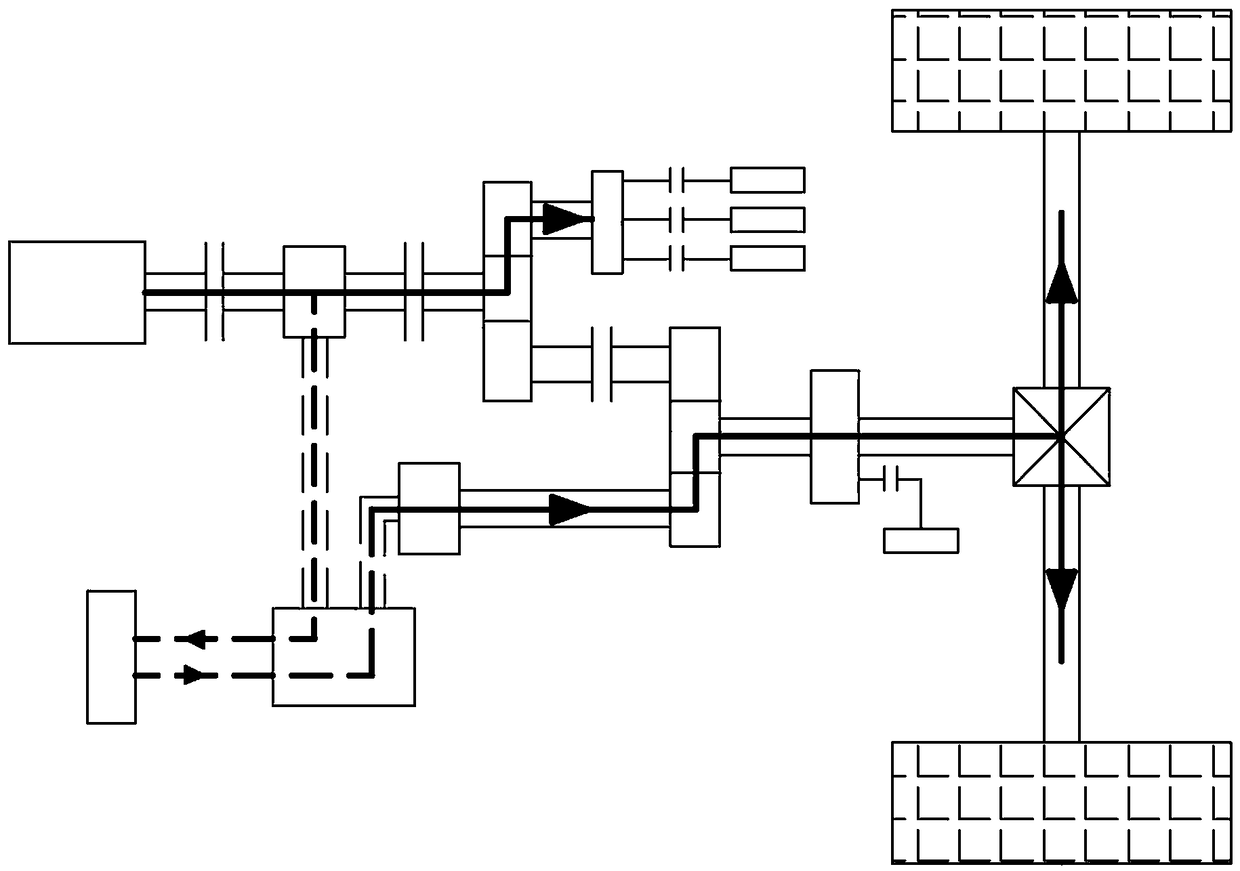

[0090] image 3 It is the transmission route diagram of the present invention under the operation mode of hybrid cleaning with insufficient electricity: the traveling device route is engine 1→clutch I2→ISG motor 3→DC / DC converter 19→battery pack 20→main motor 18→torque Coupler 16→transmission 13→transmission shaft→differential→wheel; the cleaning operation route is engine 1→clutch I2→ISG motor 3→clutch II4→power splitter 5→power take-off 6→working device. By controlling the low-pressure water pump clutch 14 to close, the low-pressure water pump 15 does not work; the high-pressure water pump clutch 8, the fan clutch 9 and the hydraulic pump clutch 7 are connected, and the high-pressure water pump 11, the fan 12 and the hydraulic pump 10 are in the working state; clutch I2, clutch II4 Combining, the clutch III17 is disconnected, part of the power output by the engine 1 charges the battery pack 20 through the ISG motor 3, and part of it provides power to the working device; the s...

Embodiment 3

[0092] Figure 4 It is the transmission route diagram under the no-load transport transfer operation mode of the present invention: at this time, the main motor 18 drives the vehicle alone, and the power transmission route is battery pack 20→DC / DC converter 19→main motor 18→torque coupling 16→ Transmission 13 → transmission shaft → differential → wheels. This process is the process of the cleaning vehicle returning to the garage from the garbage disposal area. There is no sewage in the compartment, and the cleaning vehicle is in the unloaded state in the transition mode. Similar to ordinary light trucks, its route is relatively short. Clutch Ⅰ 2, clutch Ⅱ4. The clutch Ⅲ17 is disconnected, and the vehicle is driven by the main motor 18 alone, and the real-time torque and speed of the main motor 18 are adjusted according to the required torque to meet the requirements of P mot_drive =P req_drive , this mode is the main motor drive mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com