Method and device for removing hydrogen sulfide from coal gas to prepare sulfuric acid

A hydrogen sulfide and sulfuric acid technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve problems such as environmental pollution, high operating intensity, and affecting the health of workers, and achieve the effect of reducing production costs and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

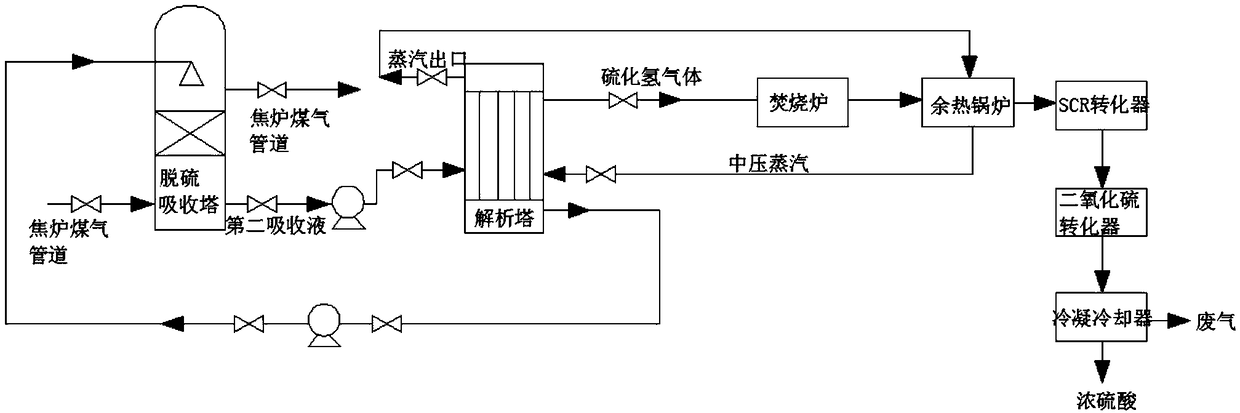

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] The invention discloses a method for preparing sulfuric acid from hydrogen sulfide in coal gas, comprising the following steps:

[0021] Step 1. Pass the coke oven gas and the first absorption liquid through the desulfurization absorption tower, and remove the hydrogen sulfide gas in the first absorption liquid to obtain the second absorption liquid rich in hydrogen sulfide. The first absorption liquid is ammonia water with a weight content of 5-10%. In the desulfurization absorption tower, the first absorption liquid inlet is located at the top, and the coke oven gas inlet is located at the bottom. There is a nozzle above the desulfurization absorption tower, and the first absorption liquid is sprayed on the coke oven gas through the nozzle to remove the coke oven gas. The hydrogen sulfide gas, the coke oven gas after hydrogen sulfid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com