Industrial wastewater treatment method

A technology for industrial wastewater and treatment methods, applied in the direction of adsorption water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as gene mutation, waste of water resources, and induction of cancer, and achieve Improved transfer efficiency, large specific surface area, and strong binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

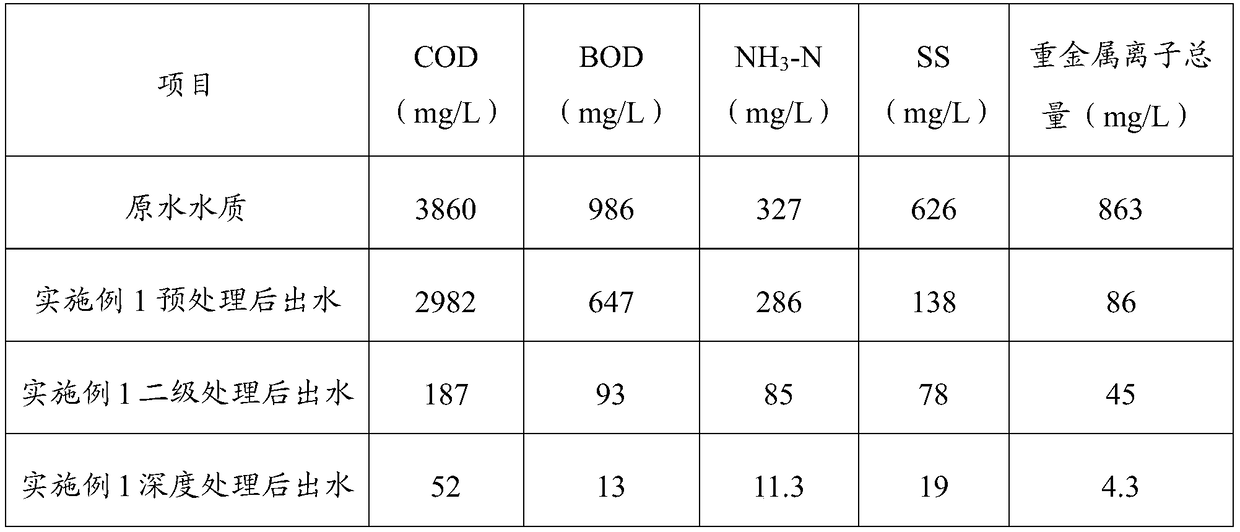

Embodiment 1

[0040] An industrial wastewater treatment method includes the following steps:

[0041] Step 1. Pretreatment of industrial wastewater

[0042] Step 1.1, homogenization: collect industrial wastewater into a homogenization tank, and stir the pool water to make the water quality uniform, and obtain raw water to be treated;

[0043] Step 1.2, filtration: filter the raw water to be treated to remove solid impurities to obtain filtered water;

[0044] Step 1.3, biosorption: filter the effluent into the biosorption tank, the dosage of the biosorption medium in the biosorption tank is 2.5g / L, and set the hydraulic load in the biosorption tank to 1.5m 3 / (m 2 ·H), after the adsorption is completed, filter to obtain the effluent of the biological adsorption pool;

[0045] Among them, the biosorption medium is composed of the following parts by weight: 20 parts of Bacillus mycoides fermentation broth, 10 parts of Pichia guttatus fermentation broth, and 50 parts of hollow glass beads with a particl...

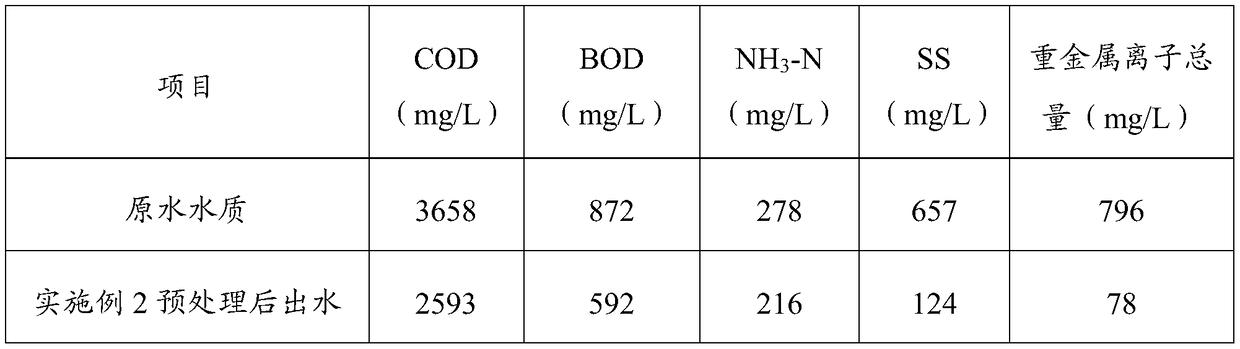

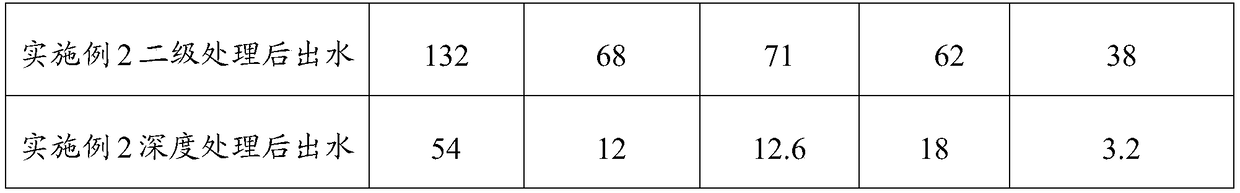

Embodiment 2

[0055] An industrial wastewater treatment method includes the following steps:

[0056] Step 1. Pretreatment of industrial wastewater

[0057] Step 1.1, homogenization: collect industrial wastewater into a homogenization tank, and stir the pool water to make the water quality uniform, and obtain raw water to be treated;

[0058] Step 1.2, filtration: filter the raw water to be treated to remove solid impurities to obtain filtered water;

[0059] Step 1.3, biological adsorption: filter the effluent into the biological adsorption tank, the dosage of the biological adsorption medium in the biological adsorption tank is 3g / L, and the hydraulic load in the biological adsorption tank is set to 1.8m 3 / (m 2 ·H), after the adsorption is completed, filter to obtain the effluent of the biological adsorption pool;

[0060] Among them, the biosorption medium is composed of the following parts by weight: 20 parts of the fermentation broth of Bacillus mycoides, 10 parts of the fermentation broth of P...

Embodiment 3

[0070] An industrial wastewater treatment method includes the following steps:

[0071] Step 1. Pretreatment of industrial wastewater

[0072] Step 1.1, homogenization: collect industrial wastewater into a homogenization tank, and stir the pool water to make the water quality uniform, and obtain raw water to be treated;

[0073] Step 1.2, filtration: filter the raw water to be treated to remove solid impurities to obtain filtered water;

[0074] Step 1.3, biological adsorption: filter the effluent into the biological adsorption tank, the dosage of the biological adsorption medium in the biological adsorption tank is 5g / L, and the hydraulic load in the biological adsorption tank is set to 2.0m 3 / (m 2 ·H), after the adsorption is completed, filter to obtain the effluent of the biological adsorption pool;

[0075] Among them, the biosorption medium is composed of the following parts by weight: 20 parts of the fermentation broth of Bacillus mycoides, 10 parts of the fermentation broth of P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com