Preparation method of macroporous strong-acidity resin and application of macroporous strong-acidity resin

A strong acid resin and reaction technology, which is applied in the field of macroporous strong acid resin preparation to achieve the effects of expanding the scope of application, being easy to recycle and reuse, and increasing bond energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

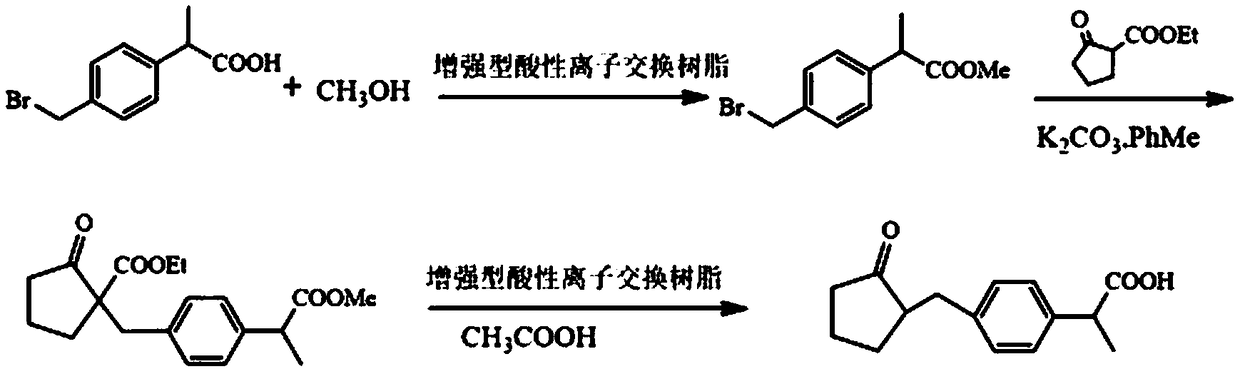

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of macroporous strongly acidic resin, concrete steps are as follows:

[0030] Step 1: Weigh p-nitrostyrene, divinylbenzene, toluene and azobisisoheptanonitrile with a mass ratio of 1:0.05:0.05:0.005, wherein the selected p-nitrostyrene has a mass of 7.458g. Mix p-nitrostyrene and divinylbenzene, wash twice with 5% (mass fraction, the same below) NaOH solution, and then wash twice with water to remove the hydroquinone inhibitor. Absolute pressure, the same below) and vacuum distillation at 45°C to obtain a purified mixture of p-nitrostyrene and divinylbenzene. Add toluene and azobisisoheptanonitrile to the mixture of p-nitrostyrene and divinylbenzene, stir and mix evenly, and then pour it into three mouthfuls of 30ml 0.2% (mass fraction, the same below) methylcellulose solution in the flask;

[0031] Step 2: Control the rotating speed to raise the temperature to 65°C under the condition of 1000r / min, and keep it for 1h; then raise the tempe...

Embodiment 2

[0034] A kind of preparation method of macroporous strongly acidic resin, concrete steps are as follows:

[0035] Step 1: Weigh p-nitrostyrene, divinylbenzene, paraffin oil and dibenzoyl peroxide with a mass ratio of 1:0.3:1.5:0.03, wherein the selected p-nitrostyrene has a mass of 7.458g. Wash twice with 5% NaOH aqueous solution, then wash twice with water to remove the hydroquinone inhibitor, and distill under reduced pressure at 10Pa and 45°C to obtain purified p-nitrostyrene and divinyl Benzene mixture. After adding paraffin oil and dibenzoyl peroxide (BPO) to the mixture of p-nitrostyrene and divinylbenzene, pour it into a three-necked flask filled with 30ml of 1.5% methylcellulose solution;

[0036] Step 2: Control the rotating speed to raise the temperature to 65°C under the condition of 4000r / min, and keep it for 3 hours; then raise the temperature to 75°C, keep it for 8 hours; then raise the temperature to 90°C, and keep it for 2 hours. Cool, filter, wash with water...

Embodiment 3

[0039] A kind of preparation method of macroporous strongly acidic resin, concrete steps are as follows:

[0040] Step 1: Weigh p-nitrostyrene, divinylbenzene, paraffin oil and dimethyl azobisisobutyrate with a mass ratio of 1: 0.16: 0.75: 0.015, wherein the quality of p-nitrostyrene selected is 7.458g. Mix p-nitrostyrene and divinylbenzene, wash twice with 5% NaOH solution, and then wash twice with water to remove the hydroquinone inhibitor, and distill under reduced pressure at 10Pa and 45°C to obtain Purified mixture of p-nitrostyrene and divinylbenzene. After adding paraffin oil and dimethyl azobisisobutyrate into the mixture of p-nitrostyrene and divinylbenzene, pour it into a three-necked flask equipped with 30ml of 0.85% polyvinyl alcohol solution;

[0041] Step 2: Control the rotational speed to raise the temperature to 65°C under the condition of 2500r / min, and keep it for 2h; then raise the temperature to 75°C, and keep it for 6h; then raise the temperature to 90°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com