High-strength flame-retardant ABS alloy material and preparation method thereof

An alloy material and high-strength technology, applied in the field of high-strength flame-retardant ABS alloy material and its preparation, can solve problems such as poor flame-retardant performance of ABS, achieve stable hydrophobic performance, improve strength and thermal stability, and improve anti-aging performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

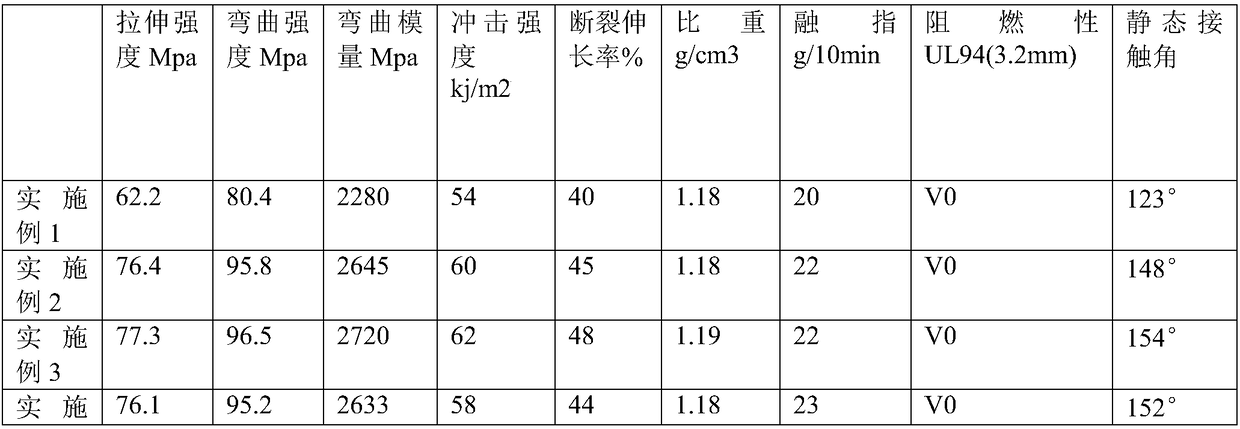

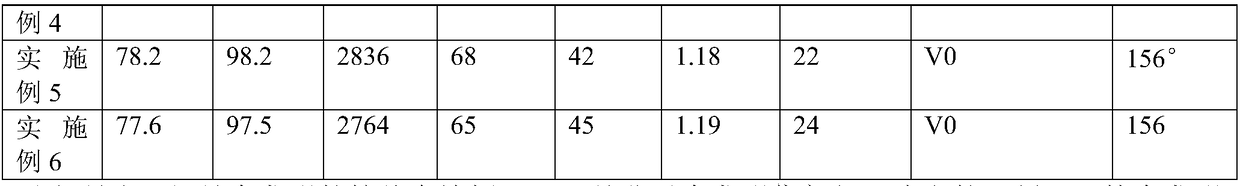

Examples

Embodiment 1

[0025] A high-strength flame-retardant ABS alloy material, including the following raw materials in parts by weight: 20 parts of acrylonitrile-butadiene-styrene copolymer, 10 parts of polycarbonate, maleic anhydride-styrene-acrylonitrile copolymer phase 3 parts of compatibilizer, 0.1 part of 1010 antioxidant, 15 parts of flame retardant. The flame retardant includes decabromodiphenylethane, antimony trioxide and polytetrafluoroethylene, and the mass ratio of decabromodiphenylethane, antimony trioxide and polytetrafluoroethylene is 1:0.1:0.4.

[0026] A preparation method of a high-strength flame-retardant ABS alloy material, comprising the following steps:

[0027] 1) Add the acrylonitrile-butadiene-styrene copolymer, polycarbonate and compatibilizer in parts by weight of the formula to the mixer and stir for 5 minutes, then add the remaining formula components and continue to stir for 10 minutes to obtain the mixed material ;

[0028] 2) Adding the mixed material into a twi...

Embodiment 2

[0030] A high-strength flame-retardant ABS alloy material, including the following raw materials in parts by weight: 20 parts of acrylonitrile-butadiene-styrene copolymer, 10 parts of polycarbonate, maleic anhydride-styrene-acrylonitrile copolymer phase 3 parts of compatibilizer, 0.1 part of 1010 antioxidant, 15 parts of flame retardant, 20 parts of modified polyurethane resin, 5 parts of glass fiber and 10 parts of modified zeolite. The flame retardant includes decabromodiphenylethane, antimony trioxide and polytetrafluoroethylene, and the mass ratio of decabromodiphenylethane, antimony trioxide and polytetrafluoroethylene is 1:0.1:0.4.

[0031] The preparation method of modified polyurethane resin is:

[0032] Mix 5 parts by weight of hydroxycitric acid, 1 part of methyl trifluoropropyl silicone oil, and 2 parts of ethylene glycol diglycidyl ether, then heat up to 60°C, react for 1 hour, and then add 30 parts of toluene diisocyanate, 10 parts Polyethylene glycol, stirred an...

Embodiment 3

[0039] A high-strength flame-retardant ABS alloy material, comprising the following raw materials in parts by weight: 30 parts of acrylonitrile-butadiene-styrene copolymer, 30 parts of polycarbonate, 4 parts of styrene-based block copolymer compatibilizer , 0.2 parts of 168 antioxidant, 16 parts of flame retardant, 25 parts of modified polyurethane resin, 6 parts of glass fiber and 12 parts of modified zeolite. The flame retardant includes decabromodiphenylethane, antimony trioxide and polytetrafluoroethylene, and the mass ratio of decabromodiphenylethane, antimony trioxide and polytetrafluoroethylene is 1:0.1:0.4.

[0040] The preparation method of modified polyurethane resin is:

[0041]Mix 6 parts by weight of hydroxycitric acid, 1 part of methyl trifluoropropyl silicone oil, and 3 parts of ethylene glycol diglycidyl ether, then heat up to 65°C, react for 1.5 hours, and then add 33 parts of toluene diisocyanate, 12 1 part of polyethylene glycol, stirring and reacting for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com