Pineapple primary pulp wine making method and intelligent fermentation apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

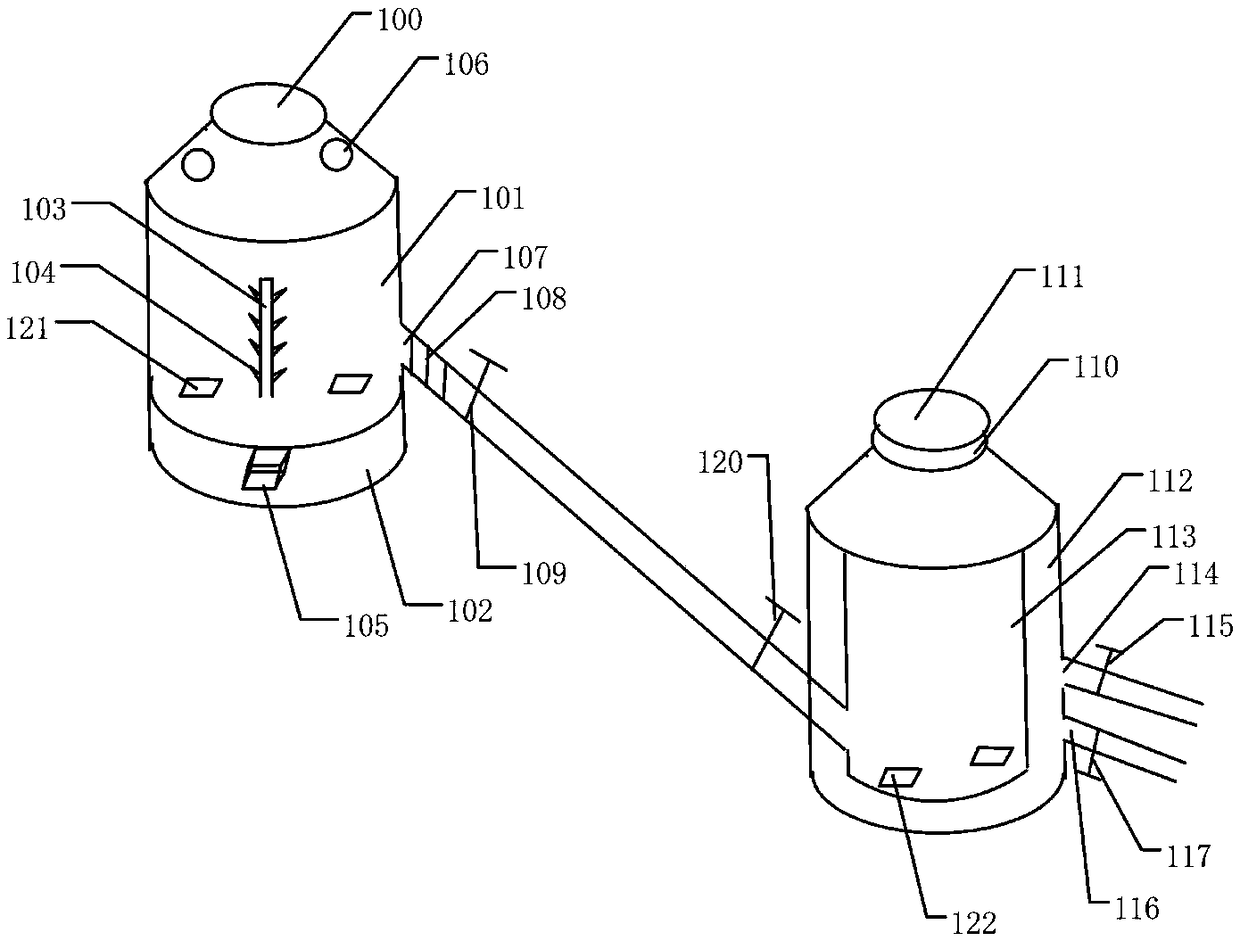

Image

Examples

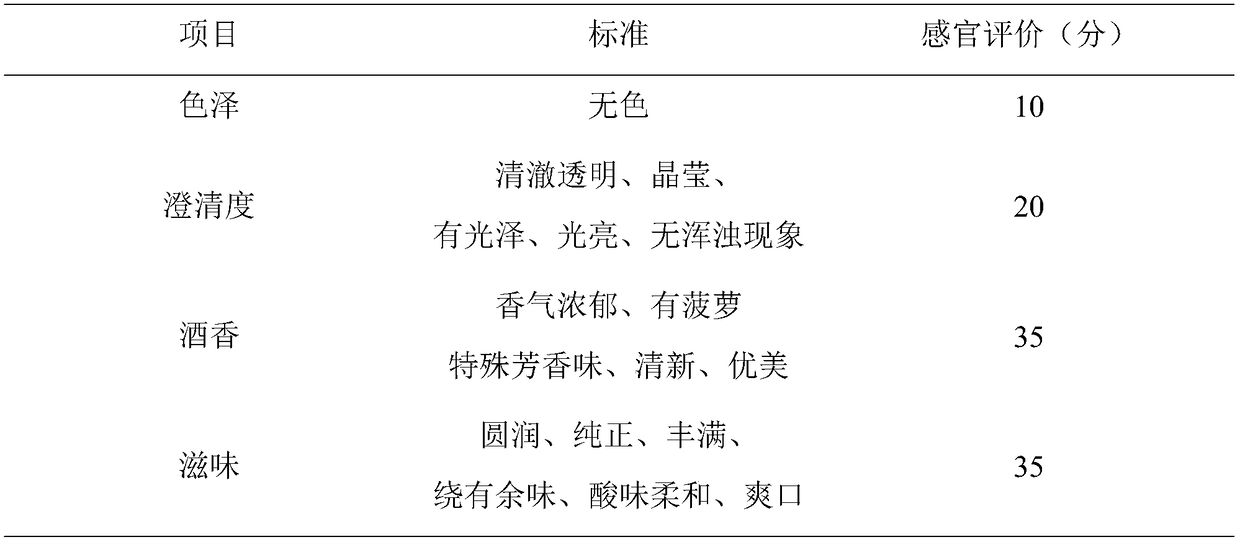

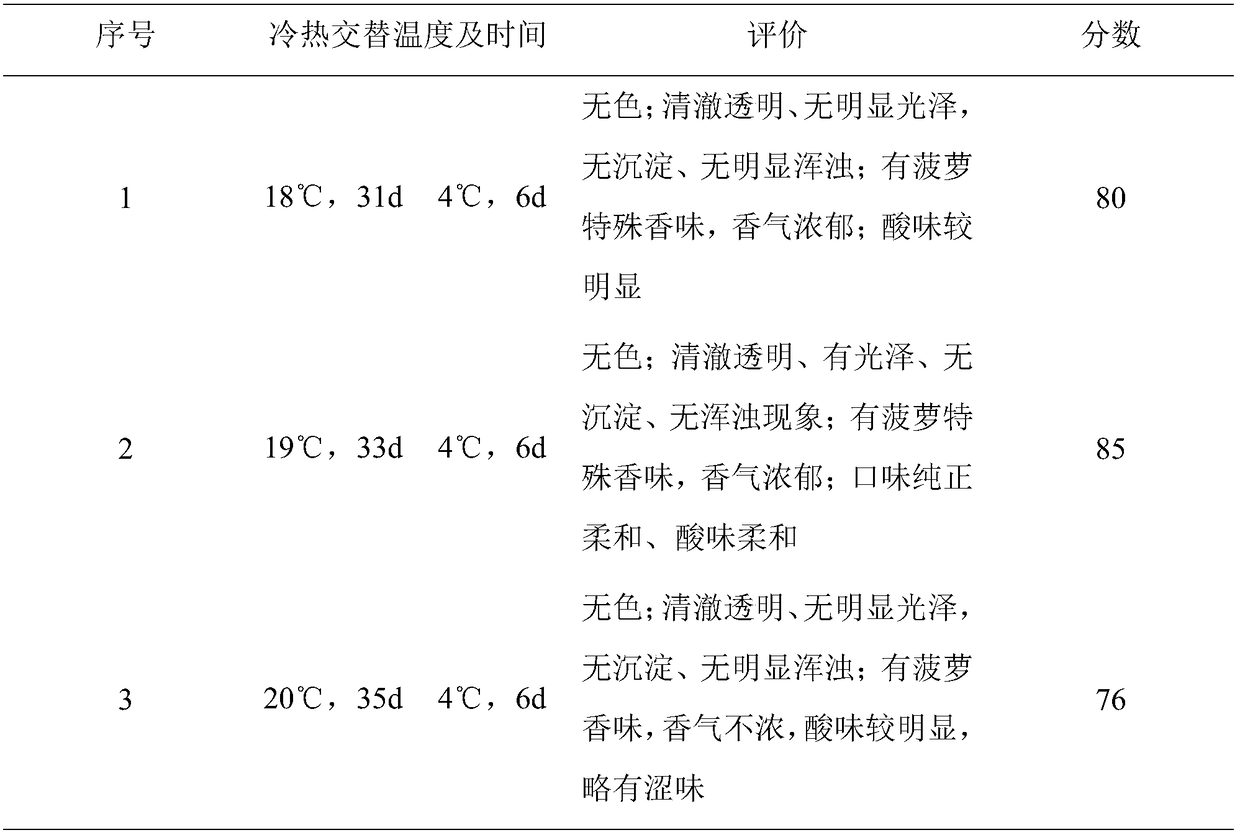

Embodiment 1

[0046] In parts by weight, after 100 parts of pineapples are peeled and cored and crushed, pretreated pineapples are obtained, and 0.5-1 part of pretreated pineapples are mixed with cellulase and pectinase in a mass ratio of 1:1 mixed with the mixed enzyme, and enzymatically hydrolyzed at 40°C for 8 hours, after the enzymolysis, the pH was adjusted to 3.0-4.0 to obtain pineapple mash;

[0047] Add dry yeast to the obtained pineapple mash by 0.6% of the total mass of pineapple, add white sugar to 10%, carry out aerobic fermentation at 22°C, carry out intermittent stirring during the fermentation process, and filter after 4 days of fermentation to obtain the first fermentation liquid;

[0048] Add solid diatomaceous earth to the obtained first fermentation broth at a mass fraction of 8%, use alternating cold and heat treatment, first seal and ferment at 18°C for 31 days, then place it at 4°C, continue to seal for 6 days, and the sugar content is 1g When the fermentation ends a...

Embodiment 2

[0053] In parts by weight, 100 parts of pineapples are peeled and cored and crushed to obtain pretreated pineapples, and the pretreated pineapples are mixed with 0.5 parts of cellulase and pectinase in a mass ratio of 1:1.2 Enzyme mixing, enzymolysis at 43°C for 9 hours, after the end of the enzymolysis, adjust the pH to 3.0-4.0 to obtain pineapple mash;

[0054] Add dry yeast to the obtained pineapple mash by 0.6% of the total mass of pineapple, add white sugar to 10%, carry out aerobic fermentation at 22°C, carry out intermittent stirring during the fermentation process, and filter after 4 days of fermentation to obtain the first fermentation liquid;

[0055] Add solid diatomaceous earth to the obtained first fermentation liquid according to the mass fraction of 8%, adopt the alternating cold and heat treatment method, first seal and ferment at 19°C for 33d, then place at 4°C and continue to seal for 6d, the sugar content is Fermentation finishes when 0.8g / L, separates and g...

Embodiment 3

[0061] In parts by weight, 100 parts of pineapples are peeled and cored and crushed to obtain pretreated pineapples, and the pretreated pineapples are mixed with 0.5 parts of cellulase and pectinase in a mass ratio of 1:1.5 Enzyme mixing, enzymolysis at 45°C for 12 hours, after the end of the enzymolysis, adjust the pH to 3.0-4.0 to obtain pineapple mash;

[0062] Add dry yeast to the obtained pineapple mash by 0.6% of the total mass of pineapple, add white sugar to 10%, carry out aerobic fermentation at 22°C, carry out intermittent stirring during the fermentation process, and filter after 5 days of fermentation to obtain the first fermentation liquid;

[0063] Add solid diatomaceous earth to the obtained first fermentation broth at a mass fraction of 8%, use alternating cold and heat treatment methods, first seal and ferment at 20°C for 35d, then place at 4°C and continue to seal for 6d, the sugar content is Fermentation ends at 1g / L, and the supernatant is separated to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com