Method for preparing high-purity rubidium by one-step thermal reduction of metallic calcium

A metal calcium, high-purity technology is applied in the field of one-step heating reduction to prepare high-purity rubidium, which can solve the problems of inability to complete continuous operation, continuous production, and difficult cleaning of pipelines, and achieve a simple and easy purification process, low cost, and convenient cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

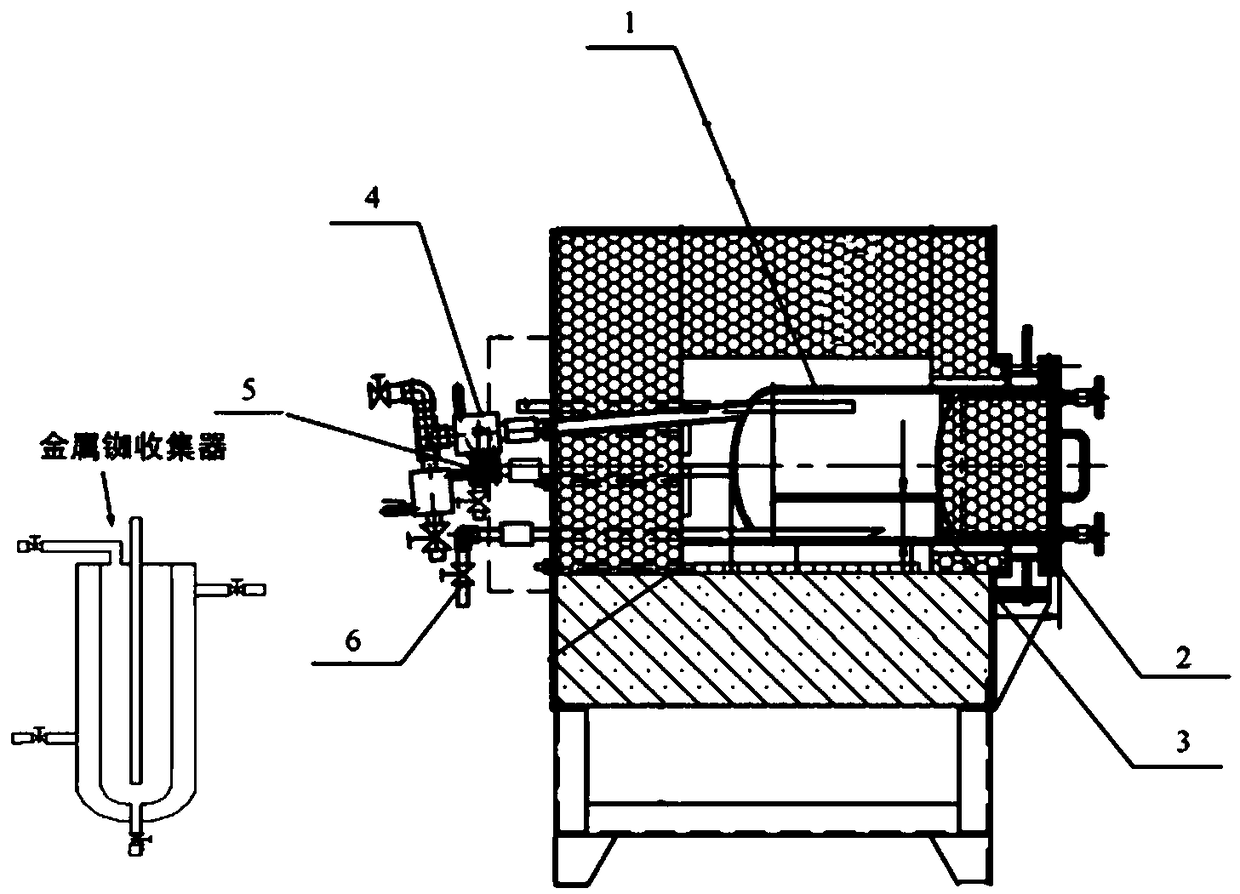

Method used

Image

Examples

Embodiment 1

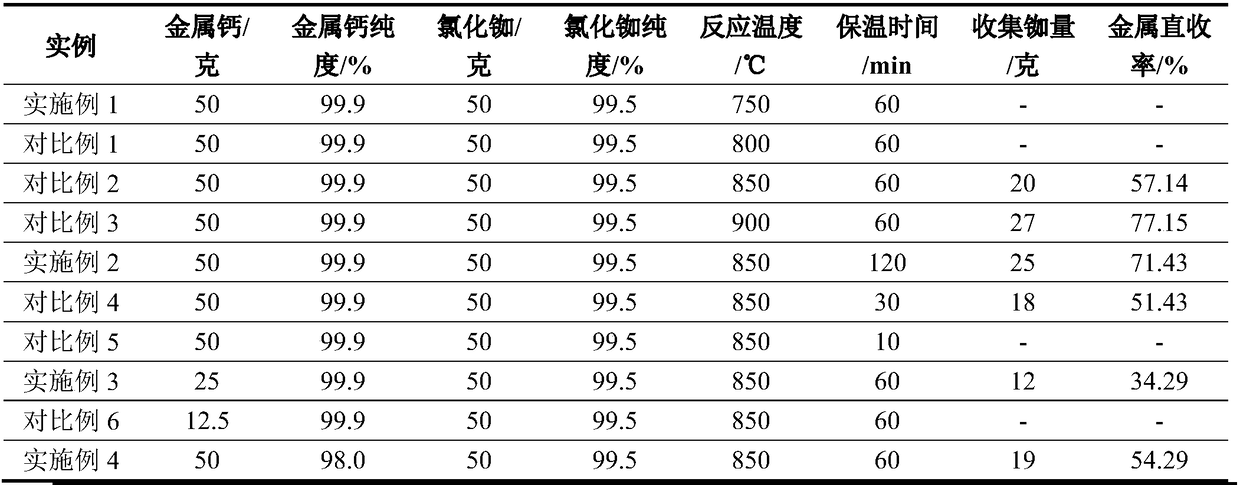

[0040] Take 50 grams of rubidium chloride powder (99.5%, white) and 50 grams of metal calcium particles (99.9%, average particle size ~5mm, silver white), mix them evenly, put them in a stainless steel pan, put them in a horizontal vacuum electric furnace, and heat Control the vacuum degree in the furnace to 0.01Pa before, pour in inert gas such as argon to normal pressure, then vacuum, and then purge the inert gas, and repeat the vacuum + inert gas to replace the oxygen in the horizontal vacuum electric furnace 3 times Above, the material was then heated to 750°C for 60 minutes under normal pressure in an inert atmosphere. The pressure did not change significantly during the entire reaction. The liquid metal rubidium was collected in a jar filled with liquid paraffin, and no liquid metal flowed out. After the heat preservation is over, turn off the heating device and open the furnace cover when the furnace temperature is cooled to room temperature. White powder is covering the ...

Embodiment 2

[0054] Take 50 grams of rubidium chloride powder (99.5%, white) and 50 grams of metal calcium particles (99.9%, average particle size ~5mm, silver white), mix them evenly, put them in a stainless steel pan, put them in a horizontal vacuum electric furnace, and heat Control the vacuum degree in the furnace to 0.01Pa before, pour in inert gas such as argon to normal pressure, then vacuum, and then purge the inert gas, and repeat the vacuum + inert gas to replace the oxygen in the horizontal vacuum electric furnace 3 times Above, the material is then heated to 850℃ for 120min under normal pressure in an inert atmosphere. The air pressure changes significantly during the whole reaction. Liquid metal rubidium can be collected with a jar filled with liquid paraffin. It is estimated that the metal rubidium is about 25 grams , The straight recovery rate of metal rubidium is 71.43%.

Embodiment 3

[0060] Take 50 grams of rubidium chloride powder (99.5%, white) and 25 grams of metal calcium particles (99.9%, average particle size ~5mm, silver white), mix them evenly, put them in a stainless steel pan, put them in a horizontal vacuum electric furnace, and heat Control the vacuum degree in the furnace to 0.01Pa before, pour in inert gas such as argon to normal pressure, then vacuum, and then purge the inert gas, and repeat the vacuum + inert gas to replace the oxygen in the horizontal vacuum electric furnace 3 times Above, the material is then heated to 850℃ for 60 minutes under normal pressure in an inert atmosphere. The pressure changes significantly during the reaction. A jar filled with liquid paraffin can be used to collect liquid metal rubidium. It is estimated that the metal rubidium is about 12 grams , The straight yield of rubidium metal is 34.29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com