Flexible display substrate material and preparation method thereof

A flexible display and substrate technology, applied in the field of flexible materials, can solve the problems of poor water vapor barrier, failure to meet the performance requirements of flexible display substrates, poor heat resistance, etc., and achieve excellent toughness, easy laser peeling, and good in-plane isotropy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing a flexible display substrate material, which is characterized in that it comprises the following steps:

[0040] a) polymerizing aromatic dianhydride, aromatic diamine and inorganic nanoparticles in a solvent to obtain a reaction solution;

[0041] b) capping the reaction solution with aminosiloxane to obtain polyamic acid slurry;

[0042] c) heat-treating the polyamic acid slurry to obtain a flexible display substrate material.

[0043] According to the present invention, the aromatic dianhydride, aromatic diamine and inorganic nanoparticles are polymerized in a solvent to obtain a reaction liquid.

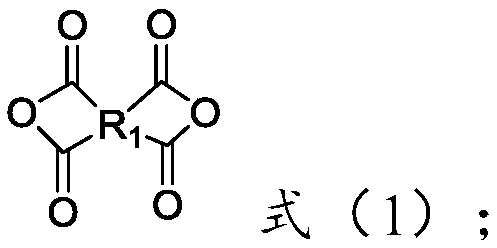

[0044] In the present invention, preferably, the aromatic dianhydride is selected from one or more of the compounds represented by formula (1);

[0045]

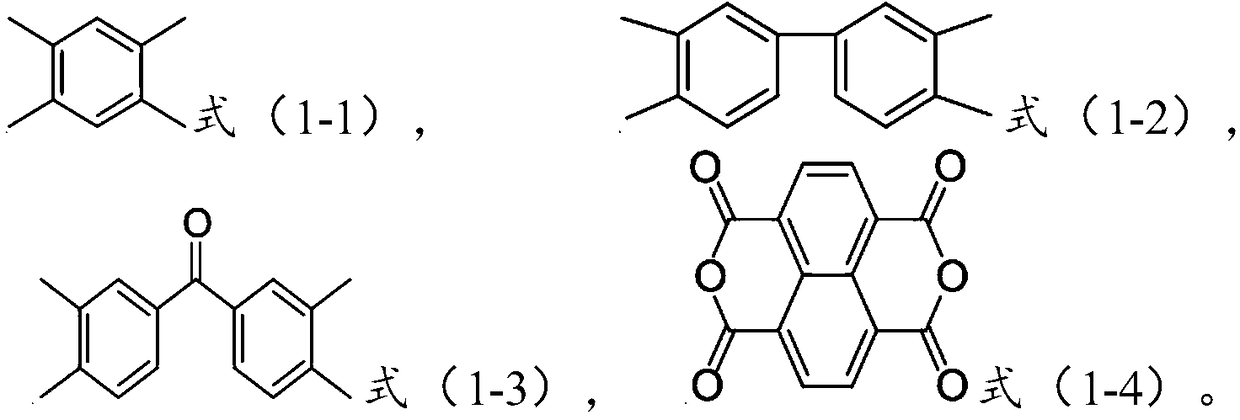

[0046] Among them, R 1 Preferably it is the structure shown in formula (1-1), formula (1-2), formula (1-3) or formula (1-4):

[0047]

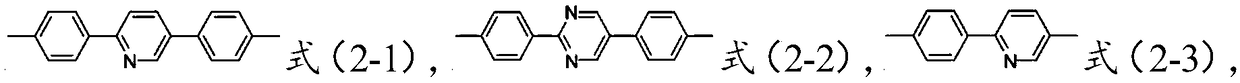

[0048] In the present invent...

Embodiment 1

[0086] 2,5-bis(4-aminophenyl)pyrimidine (1.836g, 7.00mmol), 4,4'-diaminodiphenyl ether (0.200g, 1.00mmol) and nano-silica (0.15g) were added to N , N-dimethylacetamide (25g), stirred at room temperature. Add pyromellitic dianhydride (1.845g, 8.46mmol), stir at room temperature and react for 24 hours, add aminopropyltriethoxysilane (0.204g, 0.92mmol), react for 2h, and obtain a rotational viscosity of 1×10 4 cPS polyamic acid slurry. Coat the polyamic acid slurry on the glass, place it in an oven and heat it to 400° C., and heat it for 120 minutes to obtain a polyimide-based film material.

Embodiment 2

[0088]2,5-bis(4-aminophenyl)pyridine (1.882g, 7.20mmol), 3,3′-dimethyl-4,4′-diaminobiphenyl (0.170g, 0.80mmol) and nano-oxidized Silicon (0.15g) was added into N,N-dimethylacetamide (25g), and stirred evenly at room temperature. Add 4,4'-biphenyl dianhydride (2.477g, 8.42mmol), stir at room temperature and react for 24 hours, add aminopropyltrimethoxysilane (0.151g, 0.84mmol), react for 2.5h, and the rotational viscosity is 1×10 4 cPS polyamic acid slurry. Coat the polyamic acid slurry on the glass, place it in an oven and heat it to 400° C., and heat it for 120 minutes to obtain a polyimide-based film material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com