Deep red fluorescent powder, and preparation method and application thereof

A phosphor, deep red technology, applied in the field of deep red phosphor and its preparation, can solve the problem of less research on the deep red light emission area, and achieve the effects of easy industrial production, easy availability of raw materials, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

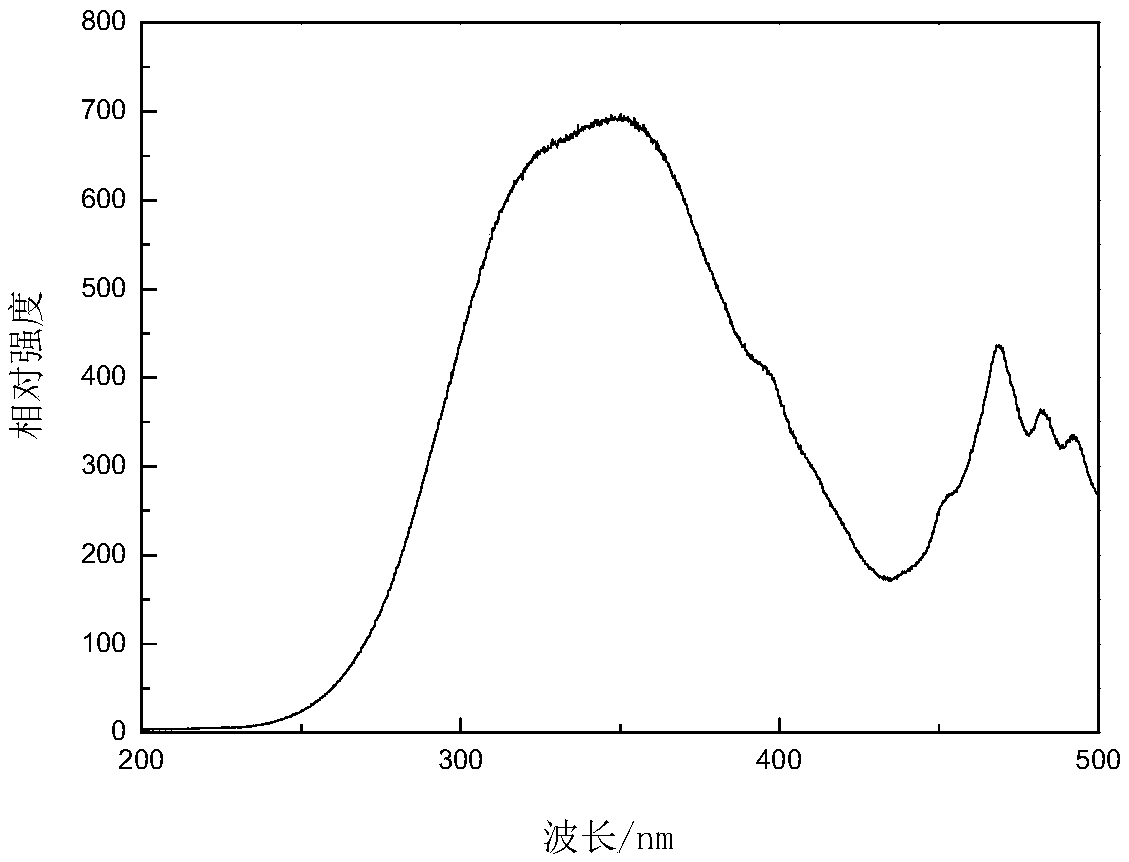

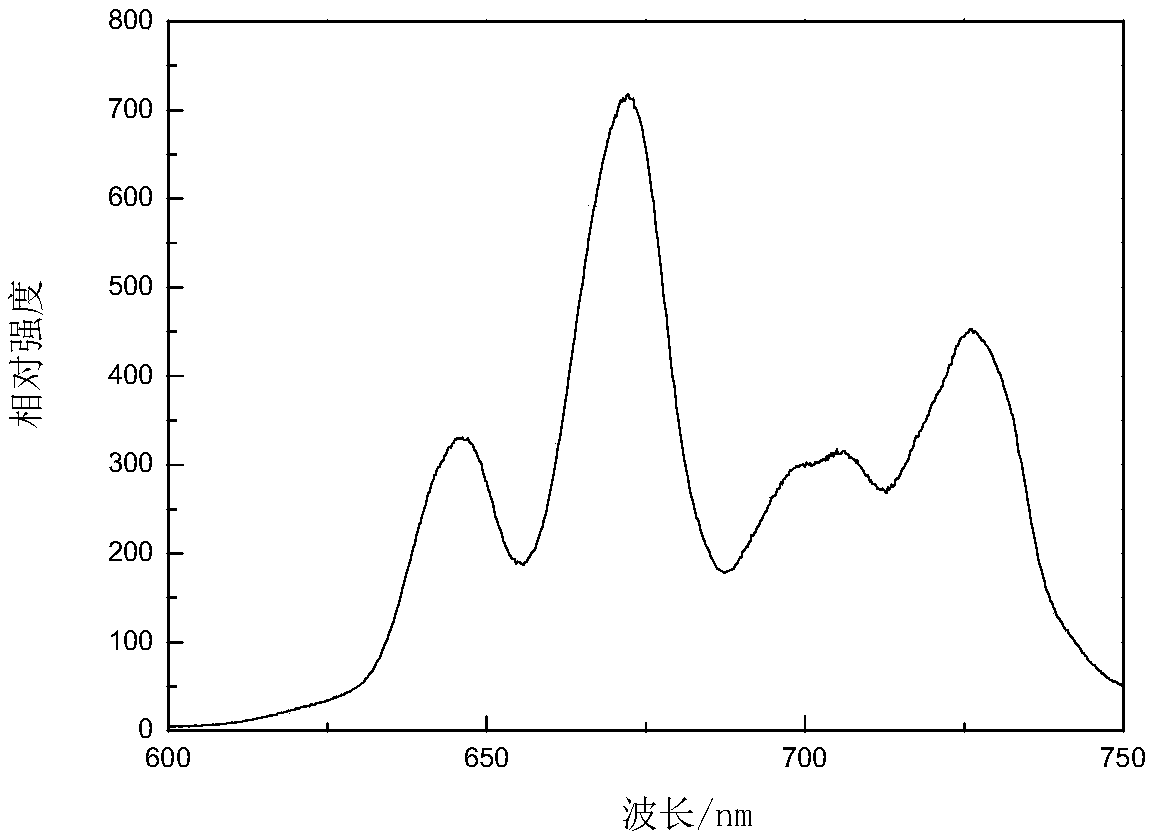

[0028] A deep red phosphor, the chemical formula of which is: Y 3-X La X al 5 o 12 : Mn, when x=0.1, that is, the chemical formula of the phosphor is Y 2.9 La 0.1 al 5 o 12 :Mn.

[0029] Follow Y 2.9 La 0.1 al 5 o 12 : Mn stoichiometric ratio Weigh yttrium oxide, lanthanum oxide, manganese carbonate, aluminum nitrate, then weigh citric acid, wherein the mol ratio of yttrium oxide, lanthanum oxide, manganese carbonate, aluminum nitrate, citric acid is 2.9:0.1:0.01: 4.99:9.6, add citric acid into water until it is completely dissolved to make an aqueous solution of citric acid; dissolve yttrium oxide and lanthanum oxide in concentrated nitric acid with a mass fraction of 68% until they are completely dissolved to make a rare earth nitrate solution; Manganese carbonate, rare earth nitrate solution and aluminum nitrate were dissolved in citric acid solution and the pH value was adjusted to neutral with ammonia water. Put it in an 80°C water bath and stir continuously u...

Embodiment 2

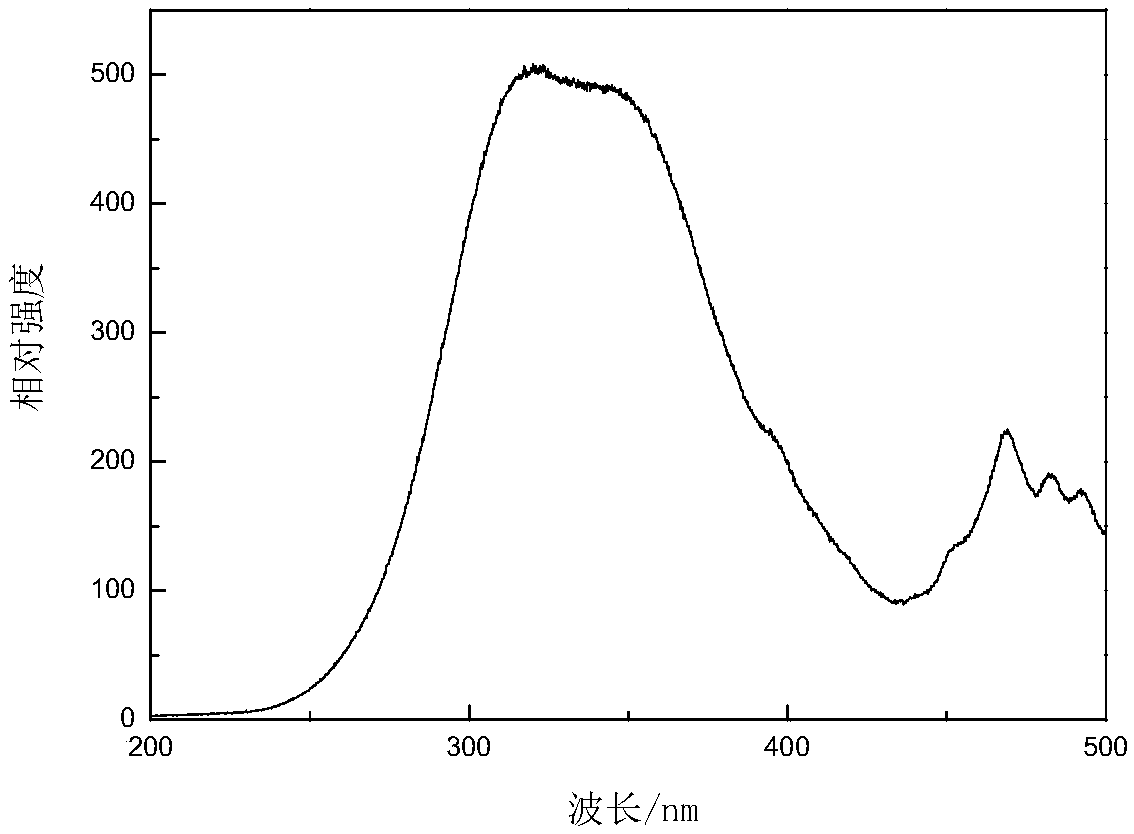

[0033] A deep red phosphor, the chemical formula of which is: Y 3-X La X al 5 o 12 : Mn, when x=0.15, that is, the chemical formula of the phosphor is Y 2.85 La 0.15 al 5 o 12 :Mn.

[0034] Follow Y 2.85 La 0.15 al 5 o 12 : Mn stoichiometric ratio Weigh yttrium oxide, lanthanum oxide, manganese carbonate, aluminum nitrate, then weigh citric acid, wherein the mol ratio of yttrium oxide, lanthanum oxide, manganese carbonate, aluminum nitrate, citric acid is 2.85:0.15:0.01: 4.99:9.6, add citric acid into water until it is completely dissolved to make an aqueous citric acid solution; dissolve yttrium oxide and lanthanum oxide in concentrated nitric acid with a mass fraction of 68% until they are completely dissolved to make a rare earth nitrate solution. Dissolve manganese carbonate, rare earth nitrate solution and aluminum nitrate in citric acid solution in turn and adjust the pH value to neutral with ammonia water. Put it in an 80°C water bath and stir continuously u...

Embodiment 3

[0038] A deep red phosphor, the chemical formula of which is: Y 3-X La X al 5 o 12 : Mn, when x=0.45, that is, the chemical formula of the phosphor is Y 2.55 La 0.45 al 5 o 12 :Mn.

[0039] Follow Y 2.55 La 0.45 al 5 o 12: Mn stoichiometric ratio Weigh yttrium oxide, lanthanum oxide, manganese carbonate, aluminum nitrate, then weigh citric acid, wherein the mol ratio of yttrium oxide, lanthanum oxide, manganese carbonate, aluminum nitrate, citric acid is 2.55:0.45:0.01: 4.99:9.6. Add citric acid into water until it is completely dissolved to make an aqueous citric acid solution; dissolve yttrium oxide and lanthanum oxide in concentrated nitric acid with a mass fraction of 68% until they are completely dissolved to make a rare earth nitrate solution; Salt and aluminum nitrate were dissolved in aqueous citric acid and the pH was adjusted to neutral with ammonia. Put it in an 80°C water bath and stir continuously until a transparent gel is formed. The gel was dried ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap