Method for improving yield of avermectin and producing strain

A technology of abamectin and strains, applied in the field of microbial genetic engineering and fermentation engineering, can solve the problems of low fermentation unit and high production cost, and achieve the effects of increasing fermentation unit, increasing yield and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

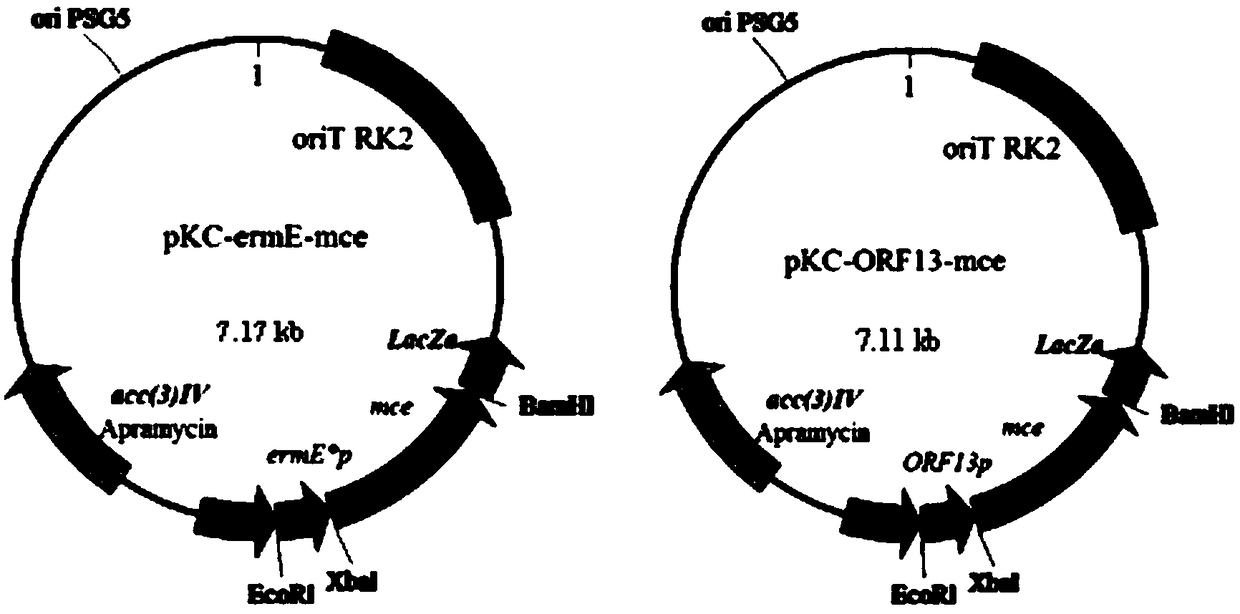

[0026] The construction of embodiment 1mce gene overexpression vector

[0027] 1. Cloning of Streptomyces avermitilis mce gene

[0028] According to the mce gene [NC_003155.5 (3499939..3500430)] in the Streptomyces avermitilis wild-type strain ATCC 31267 that Genbank announces, the sequence design PCR primer of erythromycin resistance gene ermE*p promoter and ORF13p promoter:

[0029] Primer mce_1: 5′-gctctagagtgatcgcgcgcacgttg-3′

[0030] Primer mce_2: 5′-cgggatcccaaccctaccggcccata-3′

[0031] Primer erme*p_1: 5′-cggaattcgtgtccgttcgagtggcg-3′

[0032] Primer erme*p_2: 5′-gctctagagctcaccgctggatcctac-3′

[0033] Primer orf13p_1: 5′-cggaattctgtacggcgctgattact-3′

[0034] Primer orf13p_2: 5′-gctctagaggtgacagacatggaggtctc-3′

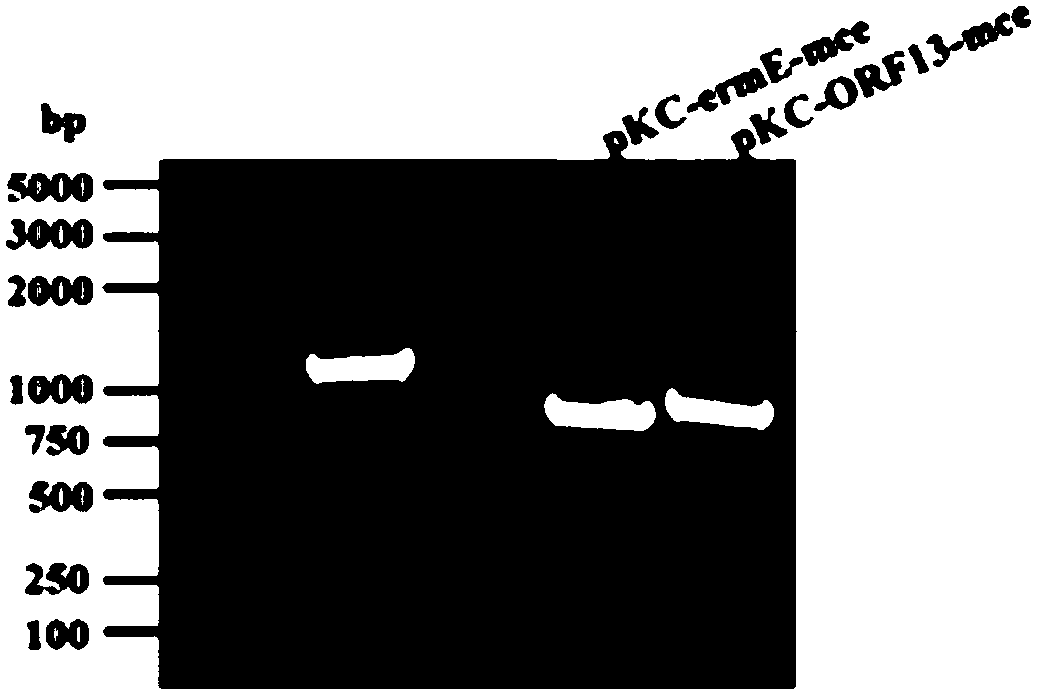

[0035]Both ends of primers mce_1 and mce_2 were respectively introduced with XbaI / BamHI restriction sites (underlined part), and both ends of ermE*p_1, ermE*p_2 and ORF13p_1 and ORF13p_2 were respectively introduced with EcoRI / XbaI restriction sites (un...

Embodiment 2

[0038] Transformation of embodiment 2 recombinant plasmids

[0039] The mce overexpression plasmids pKC-ermE-mce and pKC-ORF13-mce were constructed according to Example 1, and the original plasmid used as a control was pKC1139.

[0040] In this embodiment, the wild-type strain of Streptomyces avermitilis ATCC31267 and the high-yielding strain of abamectin 76-02-e were respectively selected as starting strains. The protoplasts of these two S. avermitilis strains were prepared, and the mce overexpression recombinant plasmids pKC-ermE-mce and pKC-ORF13-mce extracted from Escherichia coli were transformed into the wild-type strain and the avermectin high-yielding strain respectively76 The protoplasts of -02-e were spread on the protoplast regeneration medium RM14 plate respectively, and cultured at 28°C for 16-20h. When fog appeared on the plate, apply 1mL aqueous solution containing 1000μg apramycin on the plate. , continue culturing at 28°C for 7-10 days, and the grown colonies...

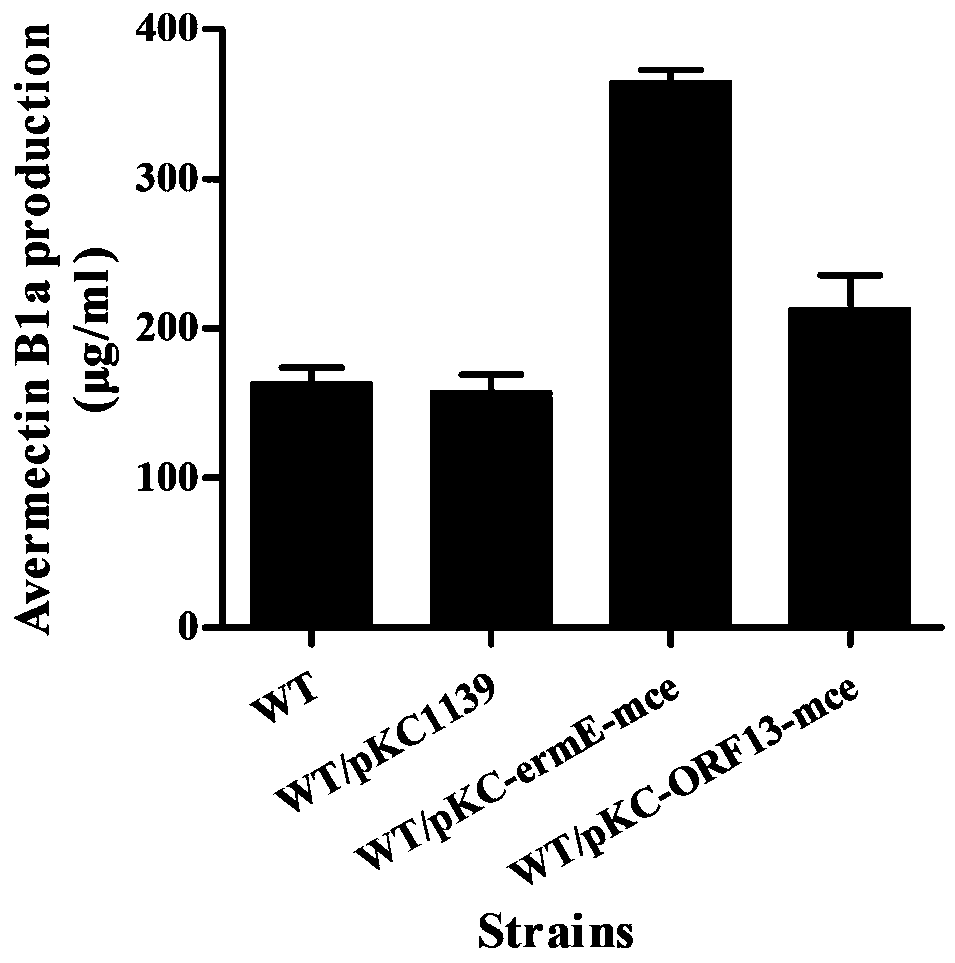

Embodiment 3

[0042] Embodiment 3 In Streptomyces avermitilis wild-type bacterial strain ATCC31267, the impact of overexpressing mce on the synthesis of abamectin

[0043] 1. Shake flask fermentation of Streptomyces avermitilis

[0044] Seed medium: 30g soluble starch, 2g malt extract, 2g soybean peptone, CoCl 2 ·6H 2 O 5mg, add distilled water to 1L, adjust pH to 7.0-7.2.

[0045] Fermentation medium: 50g soluble starch, 12g yeast powder, MgSO 4 ·7H 2 O 0.5g, K 2 HPO 4 ·3H 2 O 0.5g, KCl 4g, CaCO 3 2g, CoCl 2 ·6H 2 O 5mg, add distilled water to 1L, adjust pH to 7.0-7.2.

[0046] 2. HPLC analysis of fermentation products

[0047] Abamectin extraction: take 1.0mL fermentation broth, add 4.0mL methanol, soak for more than 30 minutes, oscillate once every 10 minutes, centrifuge at 12000rpm for 5 minutes, centrifuge twice, take supernatant and inject for analysis.

[0048] HPLC analysis conditions: C 18 Reversed-phase column, column length 150mm, column inner diameter 4.6mm, column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com