Back surface field gasb thermal photovoltaic cell and preparation method thereof

A technology of thermal photovoltaic cells and back surface field, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problem of low conversion efficiency of thermal photovoltaic cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

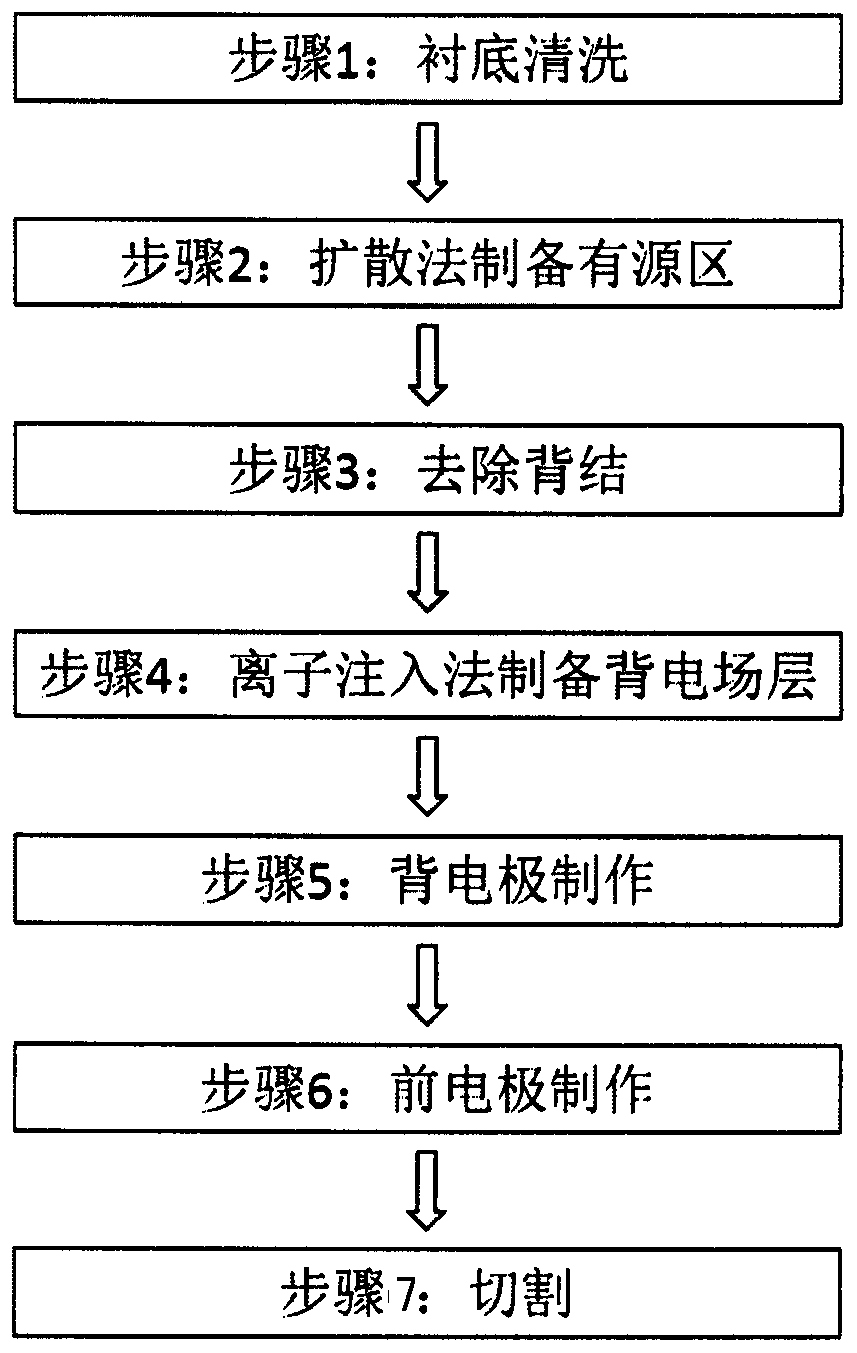

Method used

Image

Examples

Embodiment Construction

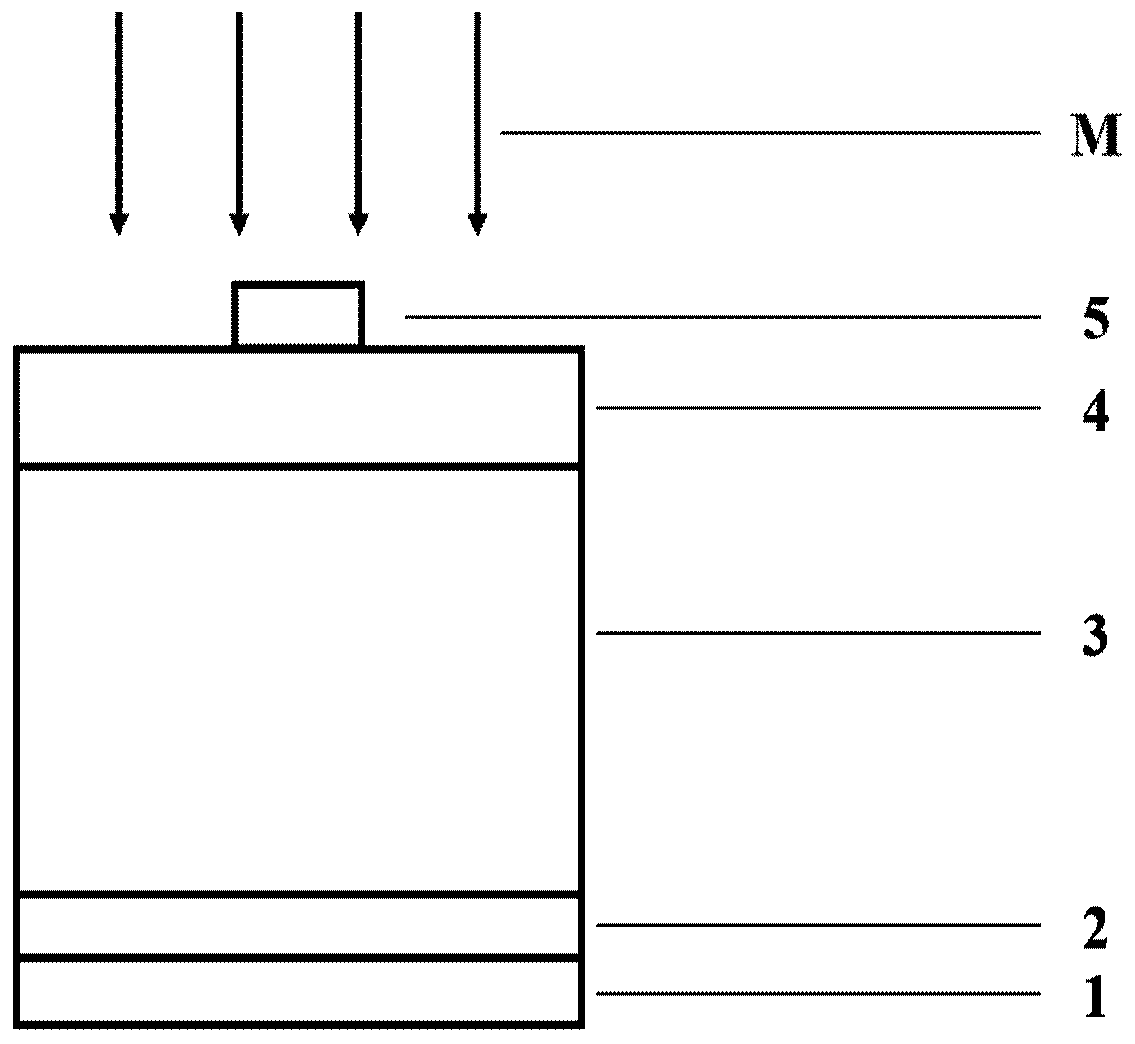

[0024] see figure 1 As shown, the present invention provides a back surface field GaSb thermal photovoltaic cell, comprising:

[0025] A substrate 3, the substrate 3 is a single wafer obtained by cutting and polishing a Te-doped n-type GaSb single crystal grown by the liquid seal Czochralski method (LEC), and the donor Te doping concentration is 5×10 16 -8×10 16 cm -3 , the crystal orientation is 2° from the (100) direction to the (110) direction, the thickness is 500 μm, and the size is 1×1cm 2 ;

[0026] An active region 4, which is made on the substrate 3, the material of the active region 4 is Zn-diffused p-type GaSb, the diffusion depth is 300-800nm, and the doping concentration is 5×10 18 -5×10 19 cm -3 ;

[0027] A back electric field layer 2, which is made on the back of the substrate 3, the material of the back electric field layer 2 is Te ion-implanted n+ type GaSb, the implantation depth is 50-75nm, and the doping concentration is 1×10 18 -1×10 19 cm -3 ; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com