Moisturizing and repairing composition for stimulating cellular water channel protein production

An aquaporin and cell-stimulating technology, which is applied in the field of moisturizing and repairing compositions that stimulate the production of cell aquaporin, can solve problems such as decreased hydration of the stratum corneum, delayed skin barrier repair, and impaired biosynthetic function, achieving Improves skin dryness, moisturizes and repairs the skin barrier, and improves the effect of bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

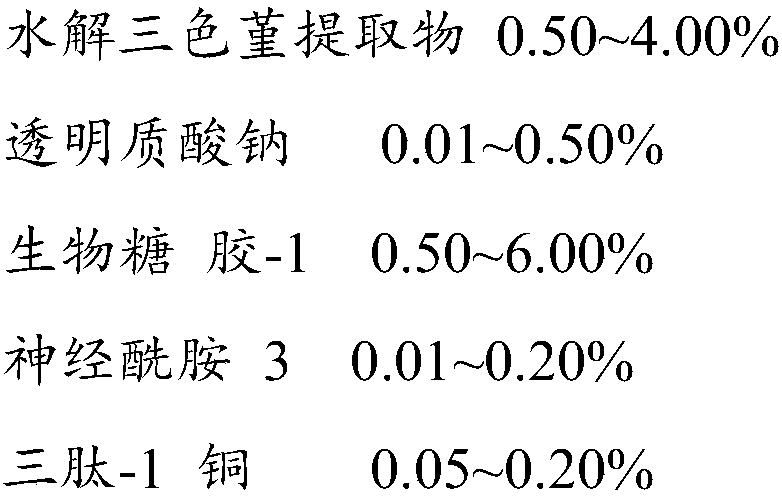

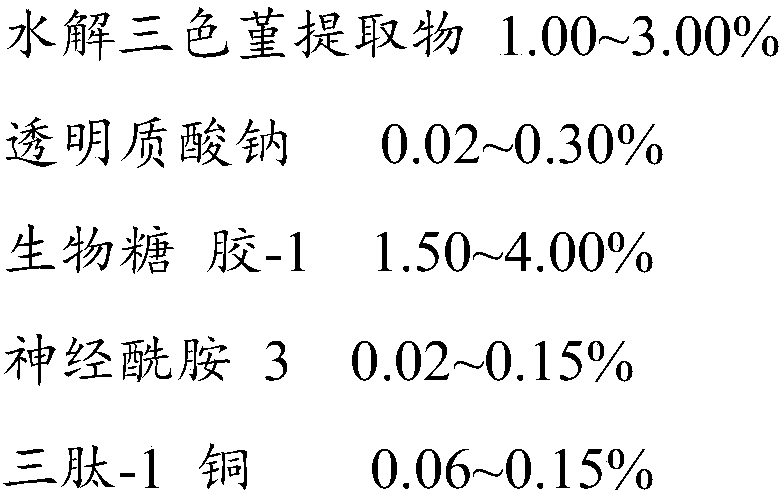

[0046] Moisturizing Repair Cream:

[0047] The components and mass percentages of the above-mentioned moisturizing and repairing cream are:

[0048] Oil phase:

[0049]

[0050] water box:

[0051]

[0052] After emulsification, add at low temperature (45°C):

[0053]

[0054]

[0055] After heating the oil phase and the water phase to 78°C respectively, mix the two phases homogeneously for 10 minutes, stir and cool down, cool down to 45°C, add hydrolyzed pansy extract, bio-glucose gum-1, 10% ceramide 3 aqueous solution and pansy Peptide-1 copper, preservatives (preservatives are routinely used in this field), essence (essences are routinely used in this field), stirred evenly, and placed at 35°C to form a white fine and uniform paste.

[0056] The hydrolyzed pansy extract is the commercially available French Celestia Bo (SILAB) company's The solid content of the hydrolyzed pansy extract is 28-42 g / L, which is only listed here and not limited.

[0057] Sodium...

Embodiment 2

[0061] Moisturizing Repair Milk:

[0062] The components and mass percentages of the above-mentioned moisturizing and repairing milk are as follows:

[0063] Oil phase:

[0064]

[0065]

[0066] water box:

[0067]

[0068] After emulsification, add at low temperature (45°C):

[0069]

[0070] After heating the oil phase and the water phase to 78°C respectively, mix the two phases homogeneously for a few minutes, stir and cool down, then cool down to 45°C and add hydrolyzed pansy extract, bio-glucose gum-1, 10% ceramide 3 aqueous solution and tripeptide -1 Copper, preservatives, flavors, stir evenly, and place at 35°C to form a white fine and uniform emulsion.

Embodiment 3

[0072] Moisturizing Gel

[0073] The components and mass percentages of the above-mentioned moisturizing and repairing gel are:

[0074]

[0075]

[0076] The preparation method of the above-mentioned moisturizing and repairing gel comprises the following steps:

[0077] (1) Mix Stabylen 30 with PNC400 and deionized water and heat to 75°C, homogenize and dissolve to obtain a uniform gel matrix;

[0078] (2) Evenly disperse butanediol and sodium hyaluronate, add it into the gel matrix while stirring, stir and disperse evenly;

[0079] (3) Stir to lower the temperature, cool down to 45°C, mix and stir the hydrolyzed pansy extract, bio-glucose gum-1, 1% ceramide 3 aqueous solution and tripeptide-1 copper, preservative and gel matrix evenly, and deionized water add to full amount;

[0080] (5) The above-mentioned gel is inspected, and after passing the test, it is then filled to obtain the moisturizing and repairing gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com