1-butene catalyst prepared through selective hydrogenation of butadiene as well as preparation method and application thereof

A technology for selective hydrogenation and butadiene, applied in catalysts, metal/metal oxide/metal hydroxide catalysts, carbon compound catalysts, etc. Advanced problems, to achieve the effect of high catalytic activity, reduced loss, and stable online operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

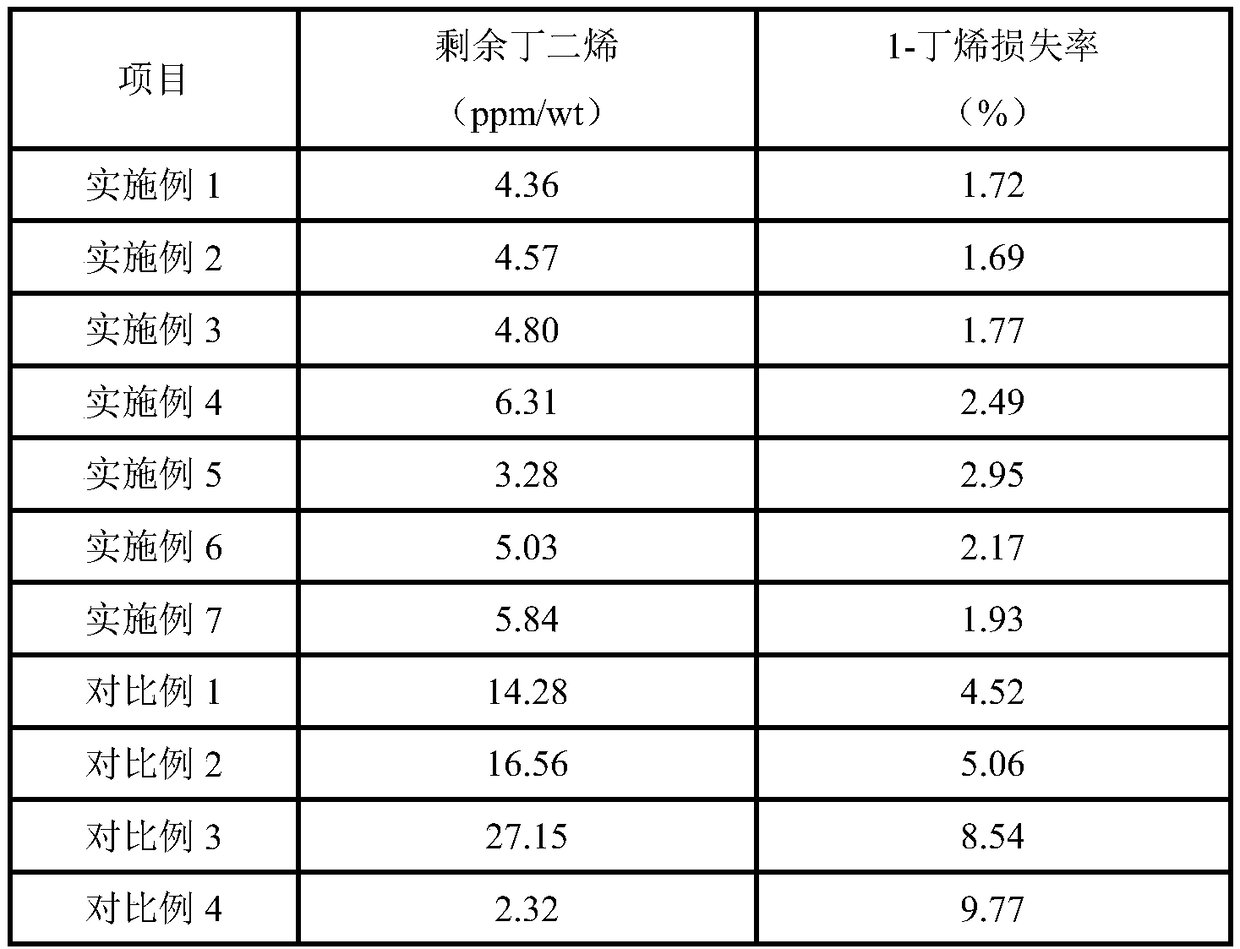

Embodiment 1

[0052] 1. Catalyst preparation

[0053] Take by weighing 70.00 grams of gamma-alumina, pseudo-boehmite with a quality equivalent to 20.00 grams of alumina, 6.00 grams of asparagus powder, 45.00 grams of citric acid monohydrate, 44.35 grams of magnesium nitrate hexahydrate (256.41), add poly Add 18.00 grams of vinyl alcohol aqueous solution (mass concentration: 5%), add 150 ml of water, extrude, dry at 80°C for 4 hours, dry at 120°C for 6 hours, and roast at 980°C for 4 hours to obtain a modified carrier .

[0054] The modified carrier was impregnated with an equal volume of 7.00 grams of manganese nitrate aqueous solution (mass concentration: 50%) (178.95) for 8 hours. After the impregnation was completed, it was aged at room temperature for 6 hours, dried at 80°C for 4 hours, and dried at 120°C for 6 hours. hour, roasting at 400°C for 4 hours to obtain a catalyst precursor; prepare an aqueous solution with a concentration of palladium nitrate dihydrate (266.46) of 0.10mol / L ...

Embodiment 2

[0060] 1. Catalyst preparation

[0061] Take by weighing 71.00 grams of gamma-alumina, pseudo-boehmite whose quality is equivalent to 20.00 grams of alumina, 6.00 grams of asparagus powder, 45.00 grams of citric acid monohydrate, 19.64 grams of magnesium nitrate hexahydrate (256.41), add poly Add 18.00 grams of vinyl alcohol aqueous solution (mass concentration: 5%), add 150 ml of water, extrude, dry at 50°C for 4 hours, dry at 120°C for 6 hours, and roast at 980°C for 4 hours to obtain a modified carrier .

[0062] The above-mentioned modified carrier and 21.20 grams of manganese nitrate aqueous solution (mass concentration: 50%) (178.95) were impregnated in an equal volume for 8 hours. After the impregnation was completed, it was aged at room temperature for 5 hours, dried at 80° C. for 4 hours, and dried at 120° C. for 6 hours. hour, roasting at 500°C for 4 hours to obtain a catalyst precursor; prepare an aqueous solution with a concentration of palladium nitrate dihydrate...

Embodiment 3

[0067] 1. Catalyst preparation

[0068] Take by weighing 71.00 grams of gamma-alumina, pseudo-boehmite whose quality is equivalent to 20.00 grams of alumina, 6.00 grams of asparagus powder, 45.00 grams of citric acid monohydrate, 32.95 grams of magnesium nitrate hexahydrate (256.41), add poly Add 18.00 grams of vinyl alcohol aqueous solution (mass concentration: 5%), add 150 ml of water, extrude, dry at 70°C for 3 hours, dry at 100°C for 5 hours, and roast at 1100°C for 4 hours to obtain a modified carrier .

[0069]The above-mentioned modified carrier and 14.00 grams of manganese nitrate aqueous solution (mass concentration: 50%) (178.95) were impregnated in an equal volume for 8 hours. After the impregnation was completed, it was aged at room temperature for 4 hours, dried at 80° C. for 4 hours, and dried at 120° C. for 6 hours. hour, roasting at 550°C for 4 hours to obtain a catalyst precursor; prepare an aqueous solution with a concentration of palladium nitrate dihydrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com