Method for improving freeze-thaw stability of maltodextrin

A freeze-thaw stability and maltodextrin technology, applied in the field of maltodextrin, can solve the problems of high content of straight-chain molecules, restrictions on products added with maltodextrin, affecting the sensory properties and shelf life of products added with maltodextrin, etc. The effect of improving branching degree and improving freeze-thaw stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

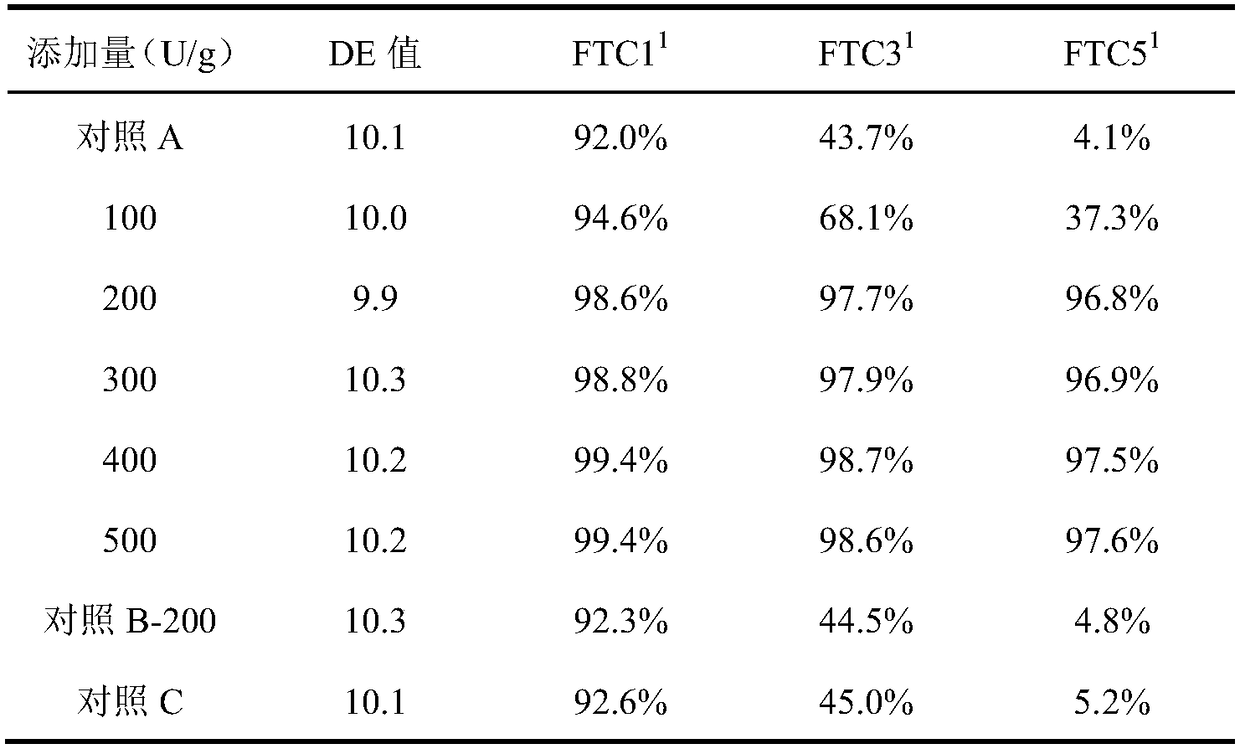

[0036] Example 1: Influence of the amount of starch branching enzyme added on the freeze-thaw stability of maltodextrin

[0037] (1) Slurry preparation: adjust the starch into 35% starch milk, keep it warm at 70°C for 30 minutes, add high-temperature-resistant α-amylase of 12U / g starch on a dry basis and 0.2% calcium chloride, and adjust the pH after stirring evenly is 6.5.

[0038] (2) Injection liquefaction: Use a low-pressure steam injection liquefier for injection. The material pressure of the first injection is 0.35MPa, the steam pressure is 0.1MPa, the temperature is 105°C, and the time is 8min. After that, it is liquefied at 90°C for 40min. Carry out the second spraying to kill the enzyme, the material pressure is 0.35MPa, the steam pressure is 0.3MPa, the temperature is 140°C, and the time is 5min.

[0039] (3) Starch branching enzyme action: After the liquefied solution in (2) is cooled below 50°C, add starch branching enzymes from Rhodothermus obamensis at 100, 200,...

Embodiment 2

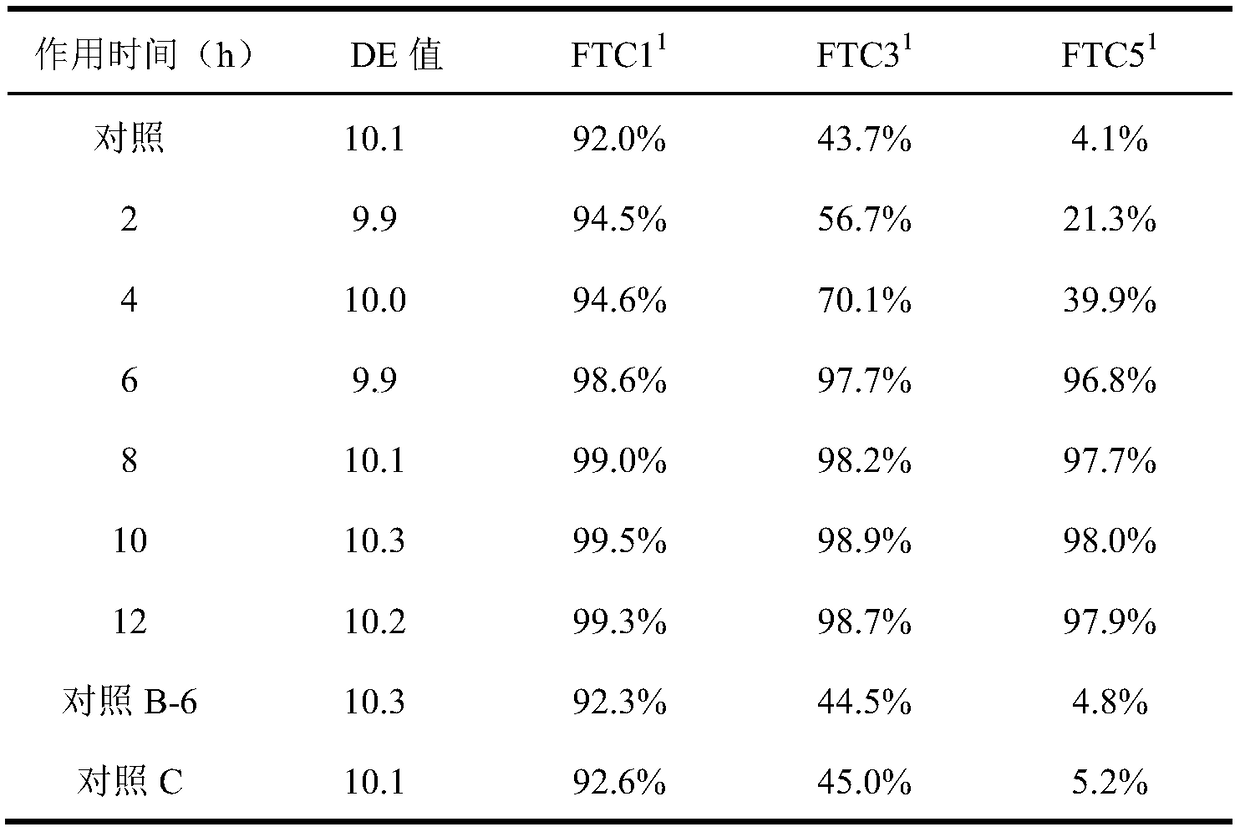

[0053] Example 2: Effect of starch branching enzyme action time on the freeze-thaw stability of maltodextrin

[0054] (1) Slurry preparation: adjust the starch into 35% starch milk, keep it warm at 70°C for 30 minutes, add high-temperature-resistant α-amylase of 12U / g starch on a dry basis and 0.2% calcium chloride, and adjust the pH after stirring evenly is 6.5.

[0055] (2) Injection liquefaction: Use a low-pressure steam injection liquefier for injection. The material pressure of the first injection is 0.35MPa, the steam pressure is 0.1MPa, the temperature is 105°C, and the time is 8min. After that, it is liquefied at 90°C for 40min. Carry out the second spraying to kill the enzyme, the material pressure is 0.35MPa, the steam pressure is 0.3MPa, the temperature is 140°C, and the time is 5min.

[0056] (3) Starch branching enzyme action: After cooling the liquefied solution in (2) below 50°C, add 200 U / g Rhodothermus obamensis starch branching enzyme on a dry basis, adjust ...

Embodiment 3

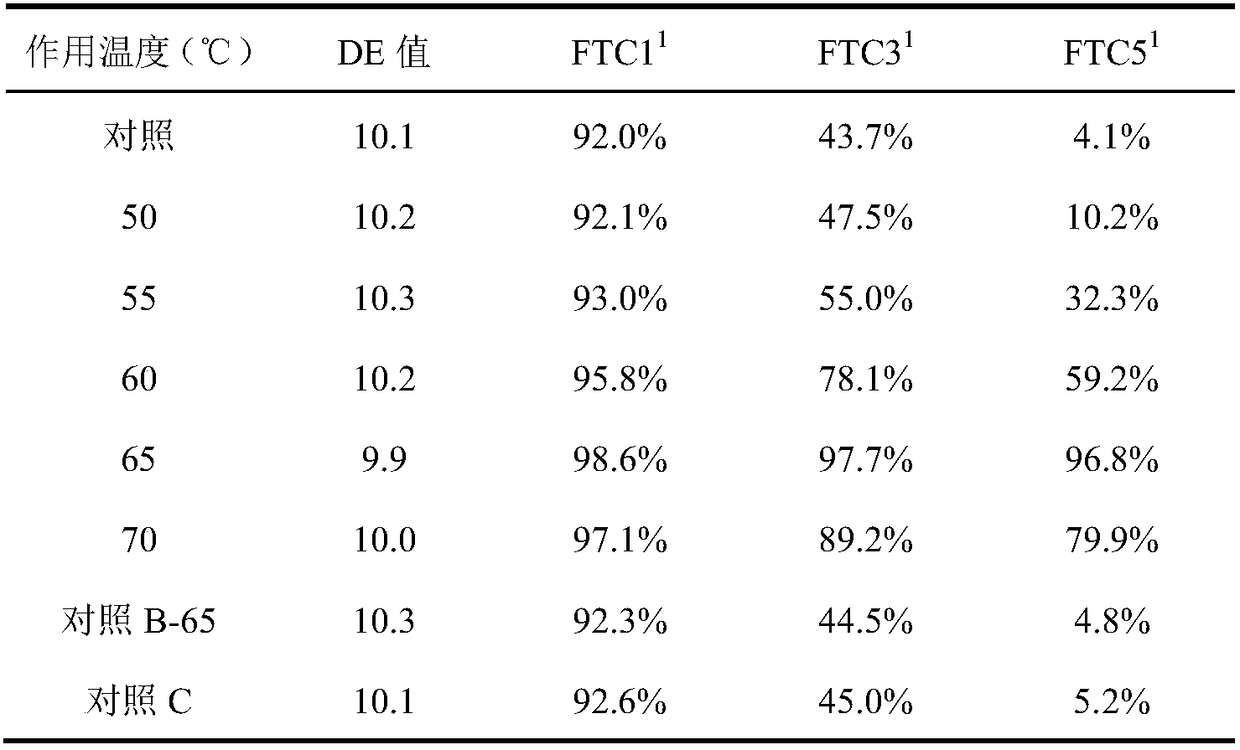

[0070] Example 3: Effect of starch branching enzyme action temperature on the freeze-thaw stability of maltodextrin

[0071] (1) Slurry preparation: adjust the starch into 35% starch milk, keep it warm at 70°C for 30 minutes, add high-temperature-resistant α-amylase of 12U / g starch on a dry basis and 0.2% calcium chloride, and adjust the pH after stirring evenly is 6.5.

[0072] (2) Injection liquefaction: Use a low-pressure steam injection liquefier for injection. The material pressure of the first injection is 0.35MPa, the steam pressure is 0.1MPa, the temperature is 105°C, and the time is 8min. After that, it is liquefied at 90°C for 40min. Carry out the second spraying to kill the enzyme, the material pressure is 0.35MPa, the steam pressure is 0.3MPa, the temperature is 140°C, and the time is 5min.

[0073] (3) Starch branching enzyme action: After the liquefied liquid in (2) is cooled below 50°C, add 200U / g Rhodothermus obamensis starch branching enzyme, adjust the pH to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com