High-strength coated fabric for oil delivery pipe and preparation method of high-strength coated fabric

An oil pipeline, high-strength technology, applied in the field of coated cloth, can solve problems such as insufficient strength, and achieve the effects of long service life, good strength and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

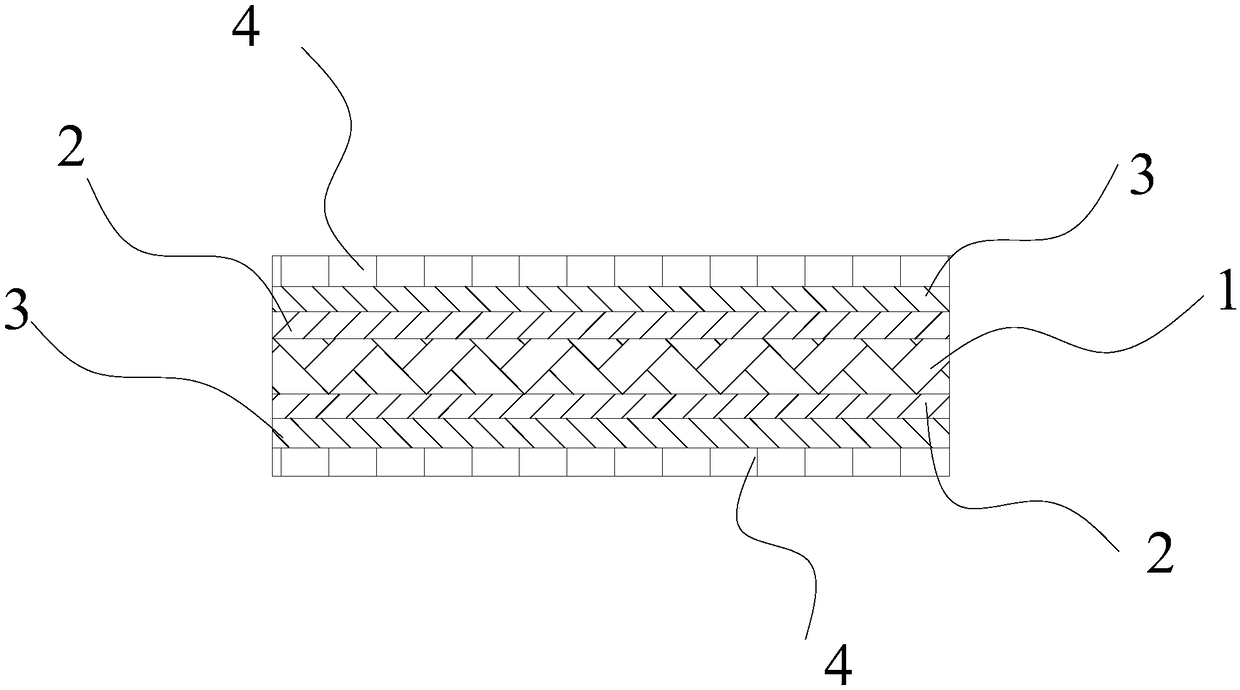

[0037] Such as figure 1 As shown, a high-strength coated cloth for oil pipelines in this embodiment includes a warp-knitted fabric 1, a first coating 2 coated on the upper and lower surfaces of the warp-knitted fabric 1, and a first coating 2 coated on each first coating 2. The second coating 3 on the outer surface and the silicone-modified acrylate layer 4 coated on the outer surface of each second coating 3 .

[0038] The paint formula of the first coating 2 is as follows: 110 parts of PSM31 type polyvinyl chloride paste resin, 65 parts of dimethyl phthalate, 20 parts of cold-resistant agent DOA, 7 parts of modified ultraviolet absorber, JLK-106 PVC plastic mold proof 6 parts, 4.5 parts of barium zinc, 28 parts of LD-100 superfine calcium carbonate, 20 parts of nano calcium carbonate, 10 parts of epoxy resin, 46 parts of halogen-free phosphorus flame retardant, 5 parts of molybdenum trioxide, 5 parts of titanium dioxide , 5 parts of zinc oxide.

[0039] The paint formula o...

Embodiment 2

[0042] Such as figure 1 As shown, a high-strength coated cloth for oil pipelines in this embodiment includes a warp-knitted fabric 1, a first coating 2 coated on the upper and lower surfaces of the warp-knitted fabric 1, and a first coating 2 coated on each first coating 2. The second coating 3 on the outer surface and the silicone-modified acrylate layer 4 coated on the outer surface of each second coating 3 .

[0043] The paint formula of the first coating 2 is as follows: 120 parts of PSM31 type polyvinyl chloride paste resin, 70 parts of diisononyl phthalate, 25 parts of cold resistance agent DOA, 9 parts of modified ultraviolet absorber, JLK-106 PVC plastic anti 9 parts of mold agent, 5.5 parts of dibasic lead phosphite, 32 parts of LD-100 superfine calcium carbonate, 25 parts of nano calcium carbonate, 14 parts of carboxymethyl cellulose, 56 parts of halogen-free phosphorus flame retardant, trioxide 7 parts molybdenum, 7 parts titanium dioxide, 7 parts zinc oxide.

[0...

Embodiment 3

[0047] Such as figure 1 As shown, a high-strength coated cloth for oil pipelines in this embodiment includes a warp-knitted fabric 1, a first coating 2 coated on the upper and lower surfaces of the warp-knitted fabric 1, and a first coating 2 coated on each first coating 2. The second coating 3 on the outer surface and the silicone-modified acrylate layer 4 coated on the outer surface of each second coating 3 .

[0048] The paint formula of the first coating 2 is as follows: 115 parts of PSM31 type polyvinyl chloride paste resin, 68 parts of phthalic acid diester, 22 parts of cold-resistant agent DOA, 8 parts of modified ultraviolet absorber, JLK-106 PVC plastic mold inhibitor 7 parts, 5 parts of calcium zinc, 30 parts of LD-100 superfine calcium carbonate, 22 parts of nano calcium carbonate, 12 parts of polystyrene, 51 parts of halogen-free phosphorus flame retardant, 6 parts of molybdenum trioxide, 6 parts of titanium dioxide, 6 parts of zinc oxide.

[0049] The paint form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com