Wear-resistant combined valve head

A combined valve and valve head technology, which is applied to valve devices, engine components, mechanical equipment, etc., can solve the problems of high molding density, increased sealing difficulty, and weakened flow capacity, so as to increase the joint area and facilitate reliable connection. The effect of stress reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

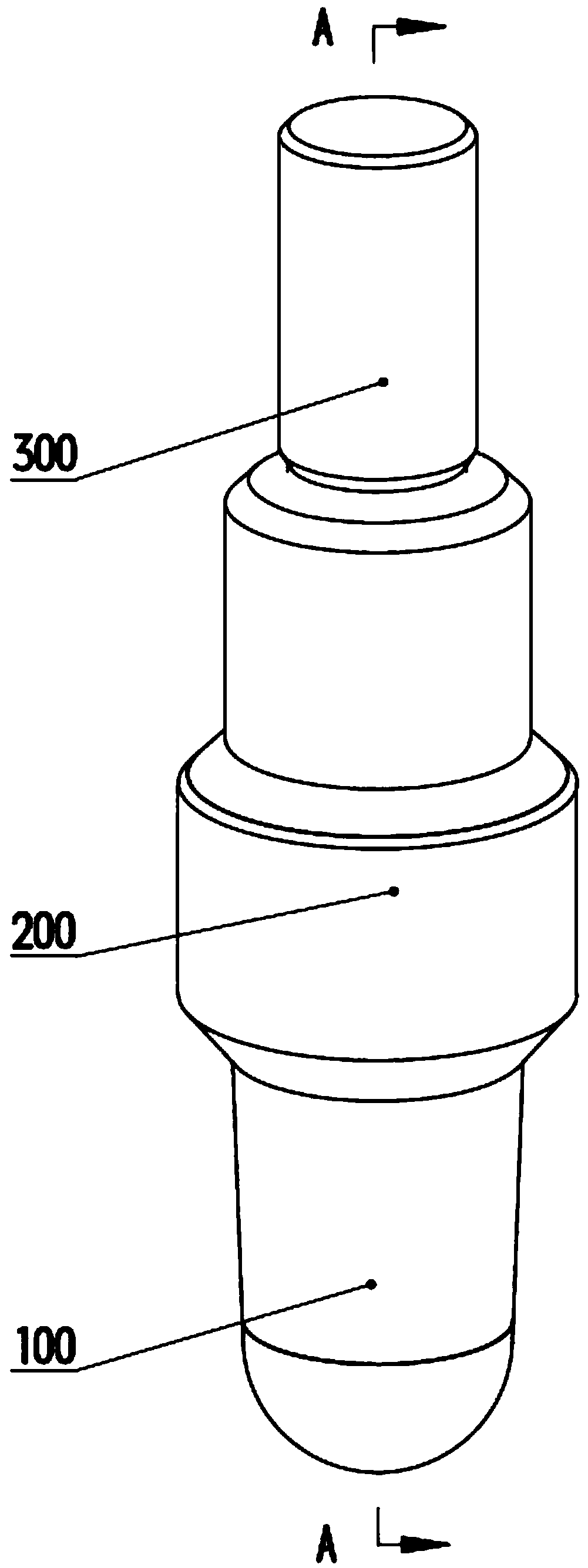

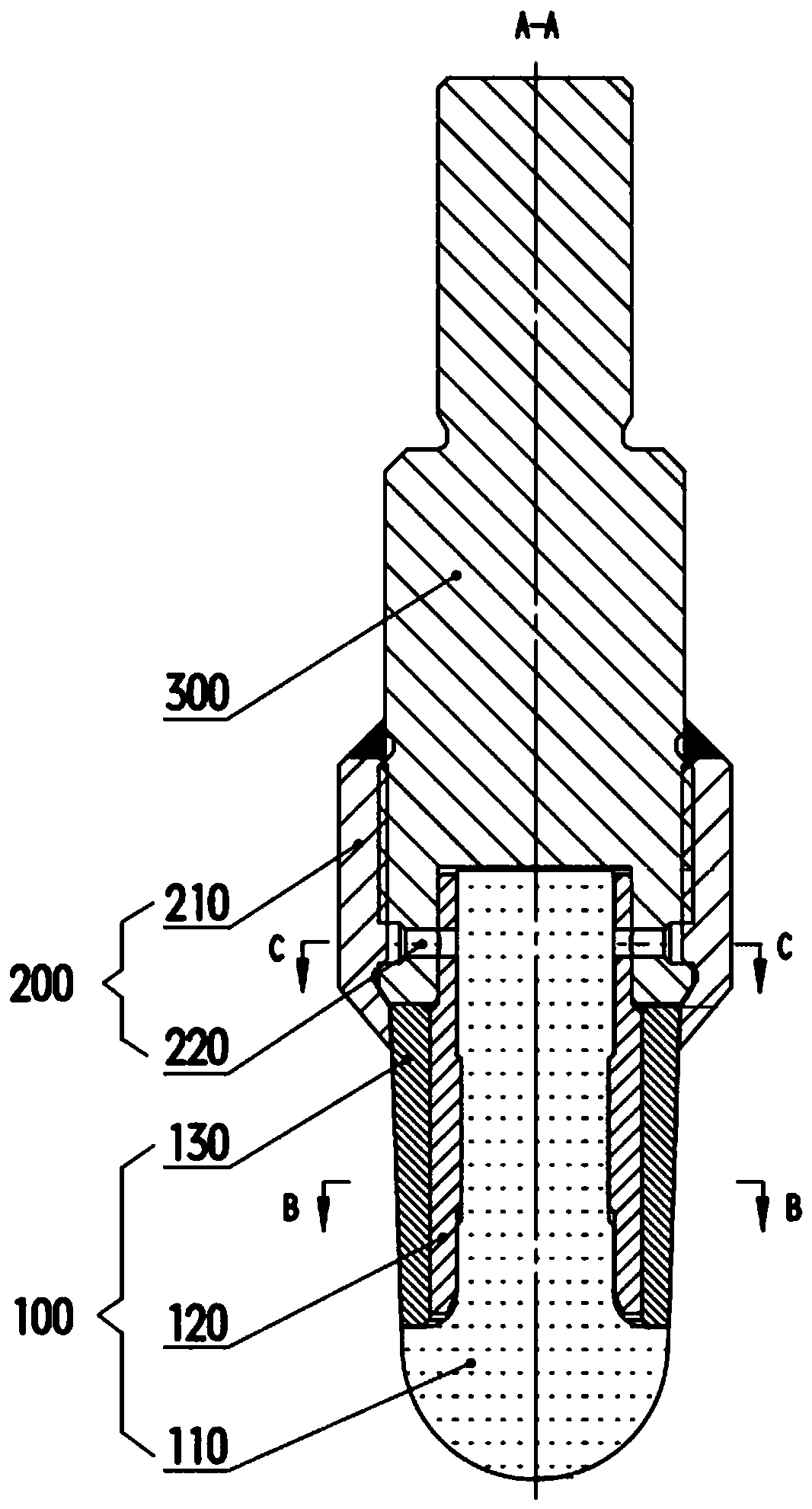

[0046] Such as Figure 1-8 As shown, a wear-resistant combined valve head of the present invention is used as a main part of a regulating valve in cooperation with a valve stem and a valve seat; it includes a valve head assembly 100, a cladding sleeve assembly 200 and a valve head seat 300;

[0047] 1. Valve head assembly 100

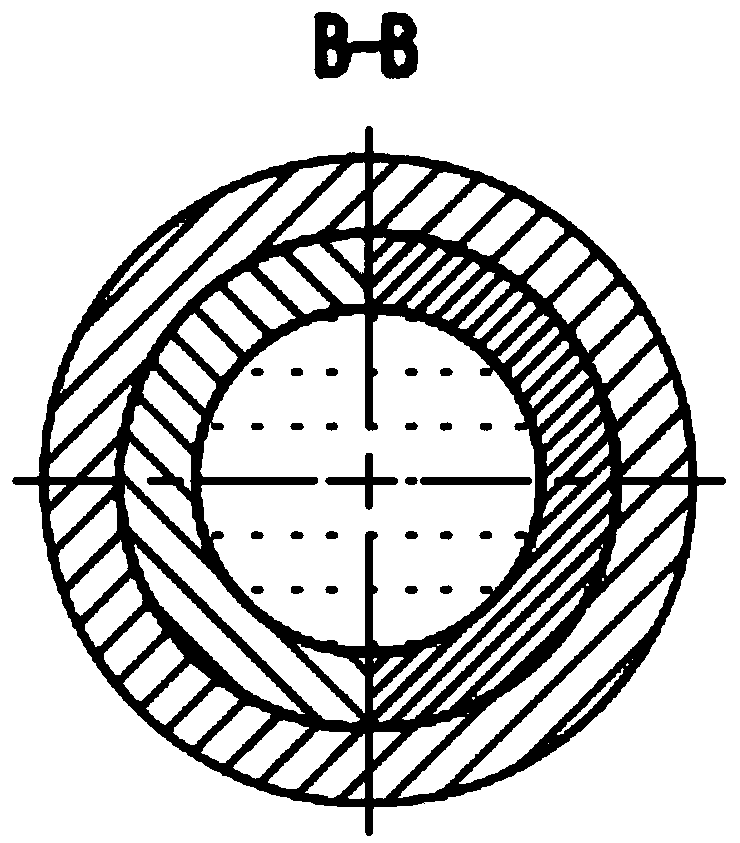

[0048] The valve head assembly 100 includes a valve head 110 and a hardened sleeve 130;

[0049] The tail of the valve head 110 is a reduced-diameter structure, and the head is the working section of the valve head assembly 100;

[0050] The two end surfaces of the hardening sleeve 130 are closely attached to the end surfaces of the valve head 110 and the valve head seat 300 respectively. The advantage of such setting is to ensure that after the material expands at the operating temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com