3D printing Ti-hydrogel-osteoblast bone tissue engineering support and preparation method thereof

A technology of bone tissue engineering and 3D printing, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of allergic reaction, unguaranteed biological safety, tumor causing, etc., and achieve good mechanical properties and good tissue integration. Properties and effects on biosafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Prepare 3D printed Ti scaffold

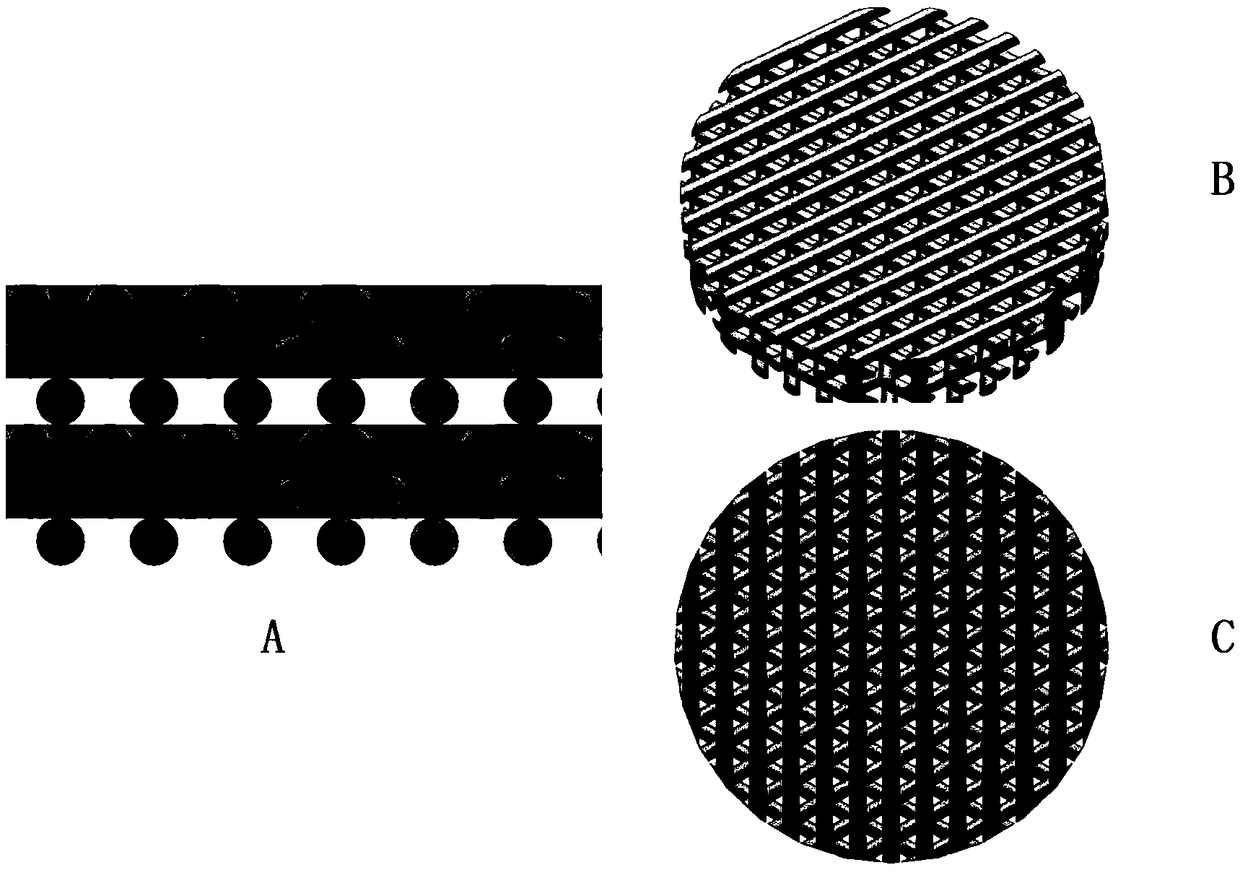

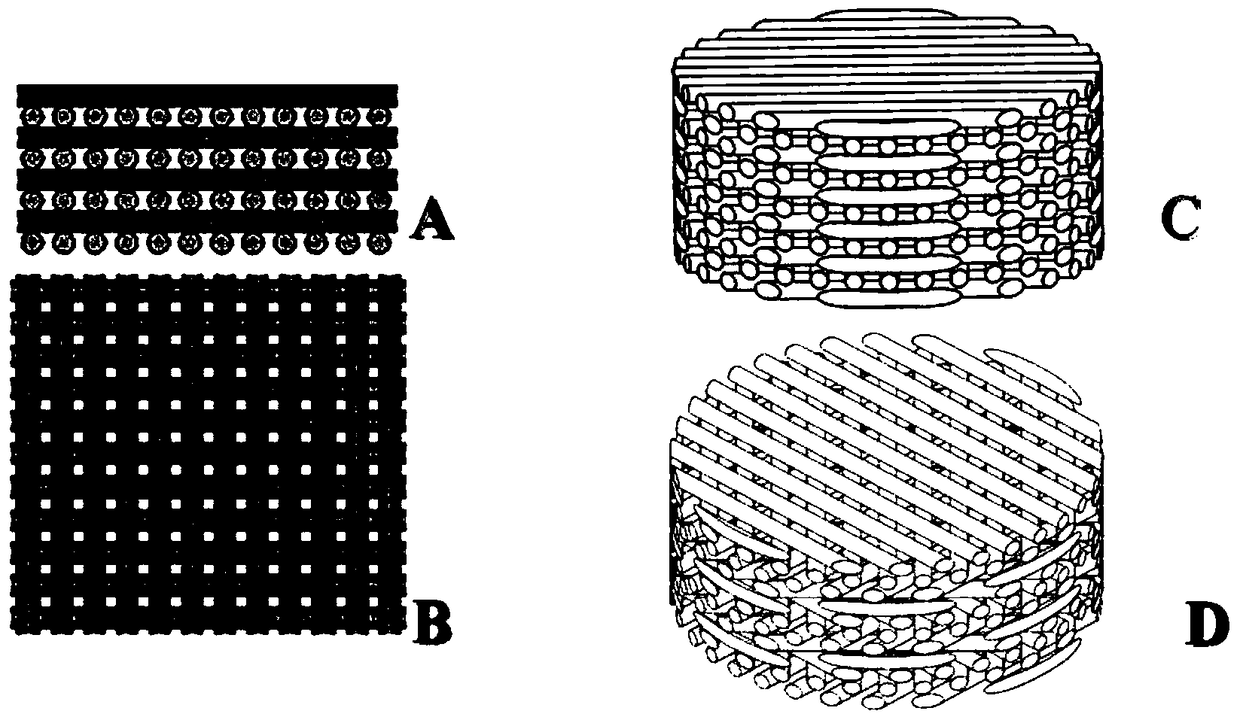

[0040] Firstly, the Ti6L4V powder was sintered into shaped fiber bundles by laser sintering (Selective Laser Sintering, SLM) technology, and the fiber bundles were arranged and spliced at 0-90°, 0-60-120°, etc. to prepare 3D printed Ti scaffolds ( figure 2 , 3 );

[0041] Step 2: Osteoblast extraction and culture

[0042] Take the calvaria of young white rabbits, cut it into pieces, add 5ml of 0.25% EDTA trypsin, digest for 30min, centrifuge to remove the supernatant, digest with 10ml of 0.1% type II collagenase for 4h, take the supernatant and centrifuge to remove the supernatant, culture medium Suspend the cells and inoculate, culture, change the medium after the cells adhere to the wall, carry out Alizarin red staining and ALP staining identification, and take 5x10 cells after amplification to the third generation 4 / ml cells for use;

[0043] Step 3: Preparation of hydrogel carrying osteoblasts:

[0044] Take agarose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com