Method for treating surface of dental material by adopting polyethylene glycol.chitosan gel

A technology of chitosan gel and dental material, applied in the field of biochemical industry, can solve the problems of high cost, need for photoactivation, poor antibacterial durability, etc., achieve good biocompatibility, avoid insufficient sterilization, and save light treatment effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

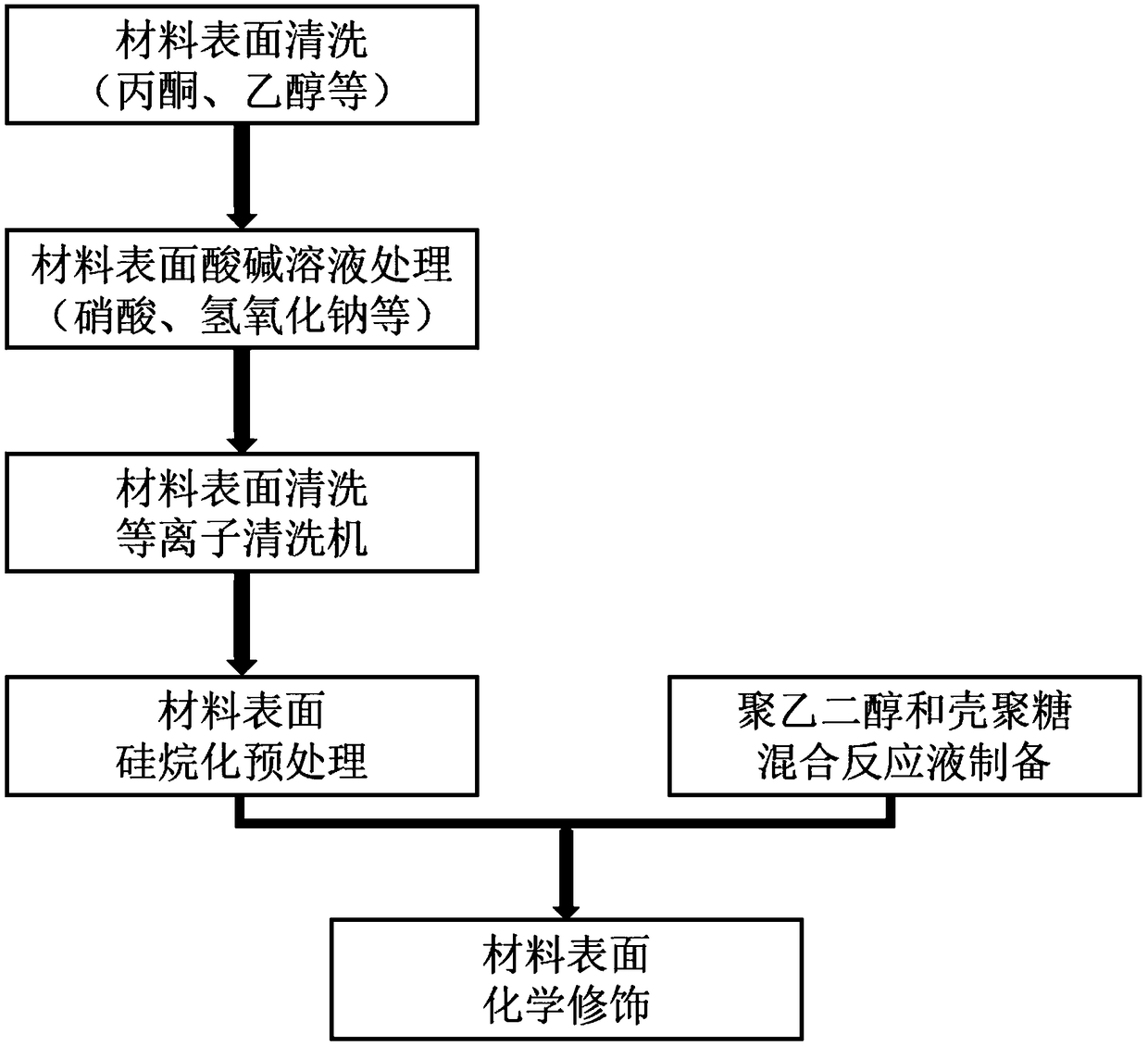

Method used

Image

Examples

Embodiment 1

[0032] In Example 1, the stainless steel arch wire in the orthodontic material was used as the experimental object.

[0033] Pretreatment: ultrasonically clean the stainless steel archwire with acetone for 15 minutes, ultrasonically clean the stainless steel archwire with ethanol for 15 minutes, rinse the surface of the archwire with deionized water, and blow dry with nitrogen to make the surface of the archwire clean and dry.

[0034] At this time, the archwires were divided into control group, PEG group and CS-PEG group.

[0035] Control group: no follow-up treatment.

[0036] The PEG group and the CS-PEG group were also processed as follows:

[0037] Soak the arch wire with 0.1wt% NaOH solution for 30s, and then use 0.1wt% HNO 3 Soak the archwire in the solution for 30s, blow dry with nitrogen to make the surface of the archwire clean and dry, and treat the surface of the archwire with a PLASMA plasma cleaner for 15min.

[0038] Preparation of silylation solution: Dissol...

Embodiment 2

[0044] In Example 2, the stainless steel bracket in the orthodontic material is used as the experimental object.

[0045] Pretreatment: ultrasonically clean the stainless steel brackets with acetone for 15 minutes, ultrasonically clean the stainless steel brackets with ethanol for 15 minutes, rinse the surface of the brackets with deionized water, and blow dry with nitrogen to make the surface of the brackets clean and dry.

[0046] At this time, the brackets were divided into control group, PEG group and CS-PEG group.

[0047] Control group: no follow-up treatment.

[0048] The PEG group and the CS-PEG group were also processed as follows:

[0049] Soak the brackets with 0.1wt% NaOH solution for 30s, and use 0.1wt% HNO 3 Soak the bracket in the solution for 30 seconds, blow it dry with nitrogen to make the surface of the bracket clean and dry, and treat the surface of the bracket with a PLASMA plasma cleaner for 15 minutes.

[0050] Preparation of silylation solution: Diss...

Embodiment 3

[0056] In embodiment 3, the nickel-titanium arch wire in the orthodontic material is used as the experimental object.

[0057] Pretreatment: Use a mixture of hydrofluoric acid, nitric acid, and water (volume ratio HF:HNO3:H2O=3:35:100) to ultrasonically clean the nickel-titanium arch wire at room temperature for 5-10 minutes, and then use deionized water to ultrasonically clean the nickel-titanium arch wire at room temperature The arch wire was dried for 5-10 minutes with nitrogen to make the surface of the arch wire clean and dry.

[0058] At this time, the archwires were divided into control group, PEG group and CS-PEG group.

[0059] Control group: no follow-up treatment.

[0060] The PEG group and the CS-PEG group were also processed as follows:

[0061] Soak the arch wire with 0.1wt% NaOH solution for 30s, and then use 0.1wt% HNO 3 Soak the archwire in the solution for 30s, blow dry with nitrogen to make the surface of the archwire clean and dry, and treat the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com