Safe and efficient formaldehyde light purification agent and preparation method thereof

A purification agent and formaldehyde technology, applied in the field of photocatalytic materials, can solve the problems of poor dispersion stability, unsafe hidden dangers, low light purification efficiency, etc., and achieve the effects of stable and long-lasting dispersion properties, safe use and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

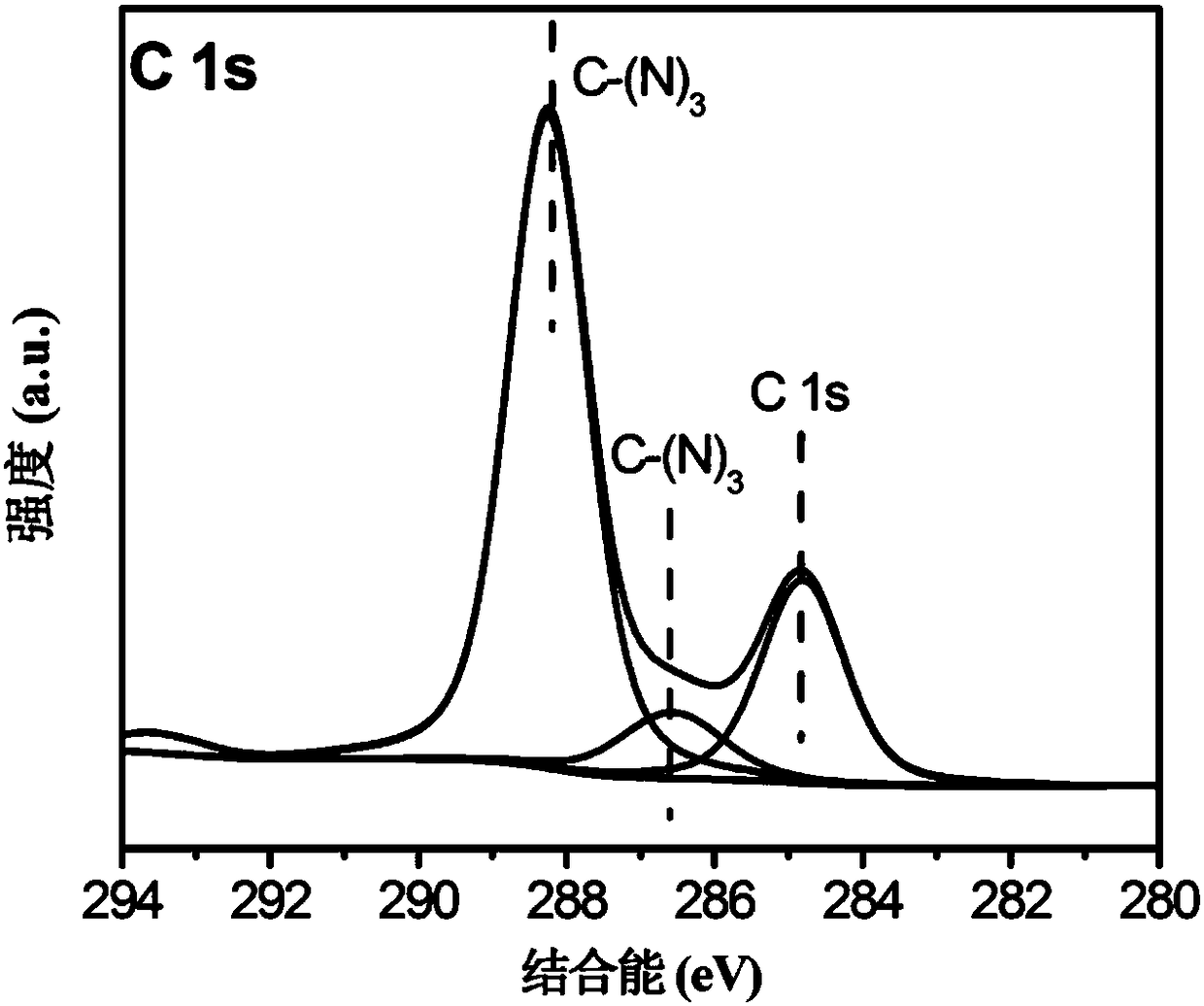

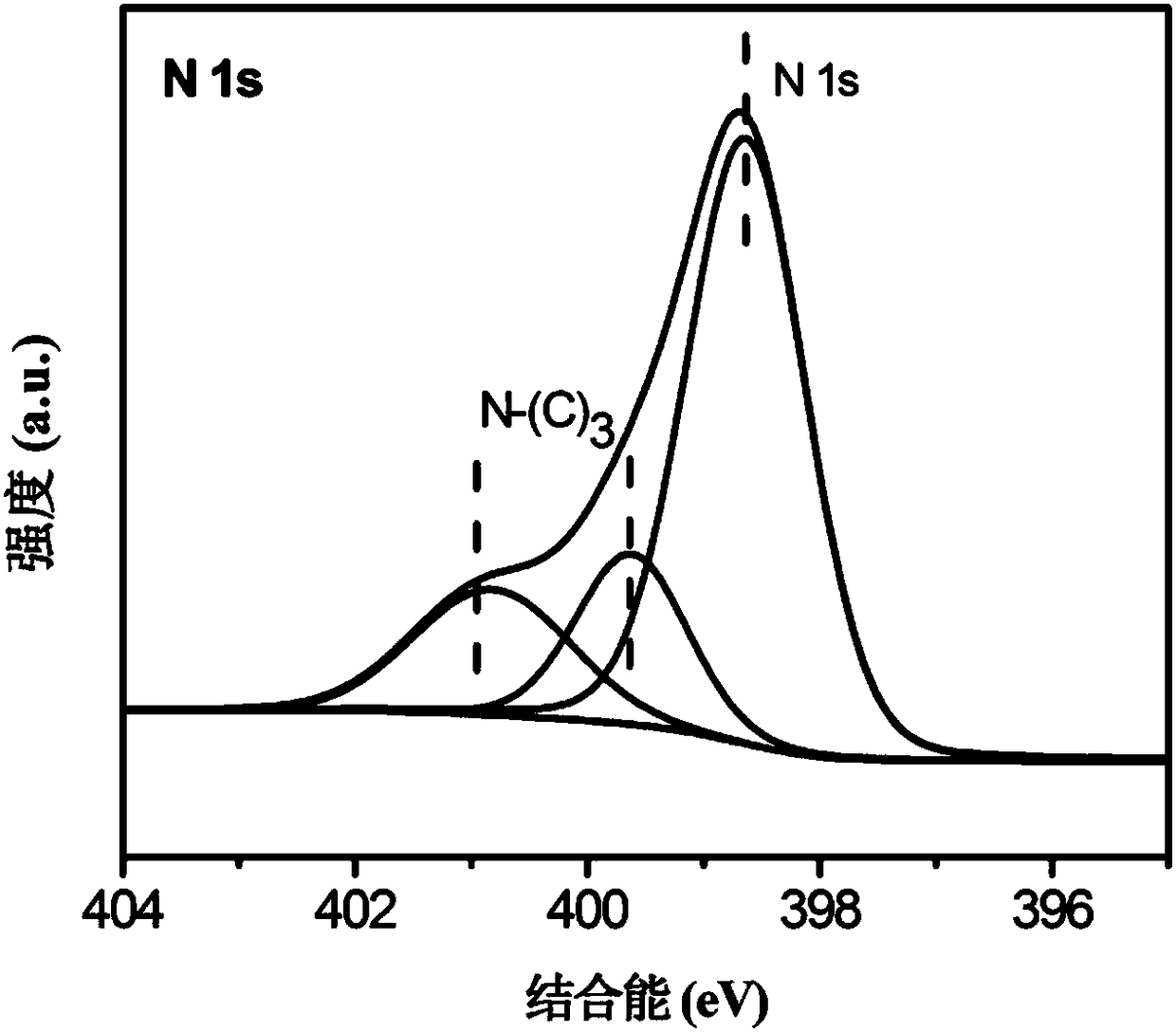

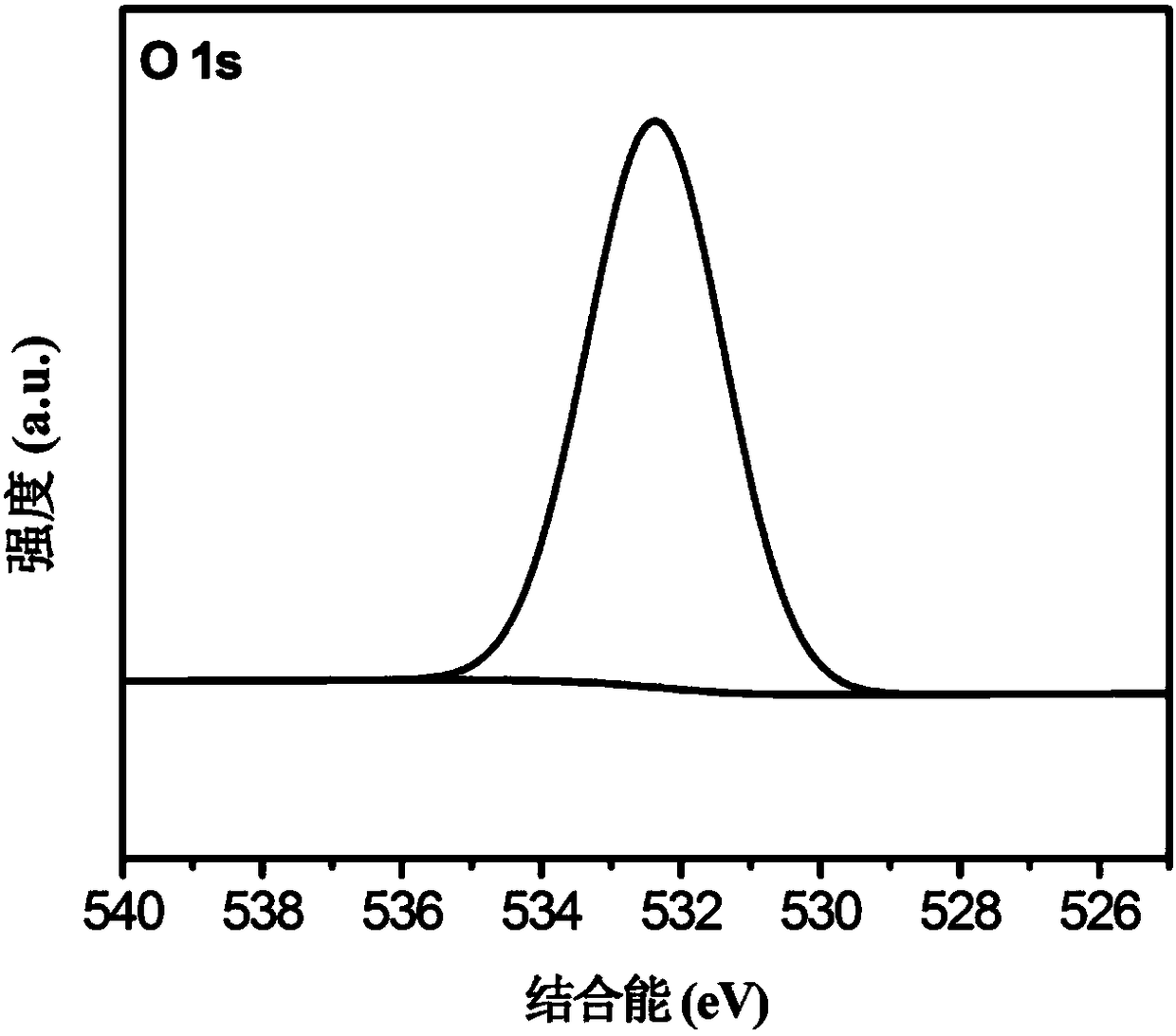

Embodiment 1

[0054]Put dicyandiamide and barbituric acid in a beaker with an appropriate amount of water at a mass ratio of 1:0.02, heat to 60°C and keep stirring for 30 minutes, and then dry it in an oven to obtain a precursor. The precursor was transferred to a crucible and calcined in a muffle furnace at a temperature of 550 °C, a holding time of 4 hours, and a heating rate of 3.0 °C / min; after natural cooling, it was ground into powder to obtain graphite phase carbon nitride ( BACN-1), weighed 1.2g BACN-1 and calcined again in a muffle furnace under air atmosphere, the calcining temperature was 500°C, the holding time was 3 hours, and the heating rate was 5°C / min. After natural cooling, a high specific surface area modified carbon nitride photocatalyst (BACN-2) was obtained. Weigh 0.1g BACN-2, disperse it in 100mL water (about 100g), use an ultrasonic machine to sonicate for 2 hours, and then use a centrifuge to obtain a light yellow suspension with a concentration of about 0.01wt% and...

Embodiment 2

[0063] Put dicyandiamide and barbituric acid in a beaker with an appropriate amount of water at a mass ratio of 1:0.01, heat to 40°C and keep stirring for 120 minutes, and then dry it in an oven to obtain a precursor. The precursor was transferred to a crucible and calcined in a muffle furnace at a temperature of 500 °C, a holding time of 6 hours, and a heating rate of 2.0 °C / min; after natural cooling, it was ground into powder to obtain graphite phase carbon nitride ( BACN-1), weighed 1.2g BACN-1 and calcined again in a muffle furnace under air atmosphere, the calcining temperature was 450°C, the holding time was 4 hours, and the heating rate was 10°C / min. After natural cooling, a high specific surface area modified carbon nitride photocatalyst (BACN-2) was obtained. Weigh 1.0g BACN-2, disperse it in 100mL water (about 100g), stir it with a mixer for 12 hours, and then let it stand for 2 days to obtain a light yellow suspension with a concentration of about 0.06wt% and a pH ...

Embodiment 3

[0065] According to the mass ratio of 1:0.1, dicyandiamide and barbituric acid were put in a beaker with an appropriate amount of water, heated to 100°C and kept stirring for 60 minutes, and then dried in an oven to obtain a precursor. The precursor was transferred to a crucible and calcined in a muffle furnace at a temperature of 620 °C, a holding time of 2 hours, and a heating rate of 4.0 °C / min; after natural cooling, it was ground into powder to obtain graphite phase carbon nitride ( BACN-1), weighed 1.2g BACN-1 and calcined again in a muffle furnace under air atmosphere, the calcining temperature was 550°C, the holding time was 1 hour, and the heating rate was 2°C / min. After natural cooling, a high specific surface area modified carbon nitride photocatalyst (BACN-2) was obtained. Weigh 0.02g BACN-2, disperse it in 100mL water (about 100g), shake it with a shaker for 24 hours, and centrifuge it with a centrifuge to obtain a light yellow suspension with a concentration of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com