Neutral formaldehyde photopurifying agent and preparation method thereof

A purification agent and formaldehyde technology, applied in the direction of chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problems of low light utilization rate of light purification agents, unsafe hidden dangers, poor dispersion stability, etc., to achieve safe use , thorough purification, stable dispersion and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Put 10g of dicyandiamide in a crucible and cover it, calcined in a muffle furnace, the calcining temperature is 550°C, the holding time is 4 hours, and the heating rate is 2.0°C / min; after natural cooling, it is ground into powder to obtain graphite phase nitrogen Carbonization (CN-D-1), weighed 1.2g, put it in a crucible without a cover, spread it out, and calcined again. The calcining temperature was 500°C, the holding time was 3 hours, and the heating rate was 5.0°C / min. After natural cooling, a high specific surface area carbon nitride photocatalyst (CN-D-2) was obtained. Weigh 0.1g CN-D-2, disperse it in 100mL water (about 100g), crush it with a cell crusher for 0.5h, and then centrifuge it with a centrifuge to obtain a milky white suspension with a concentration of about 0.01wt% and a pH of about 6~ 7.

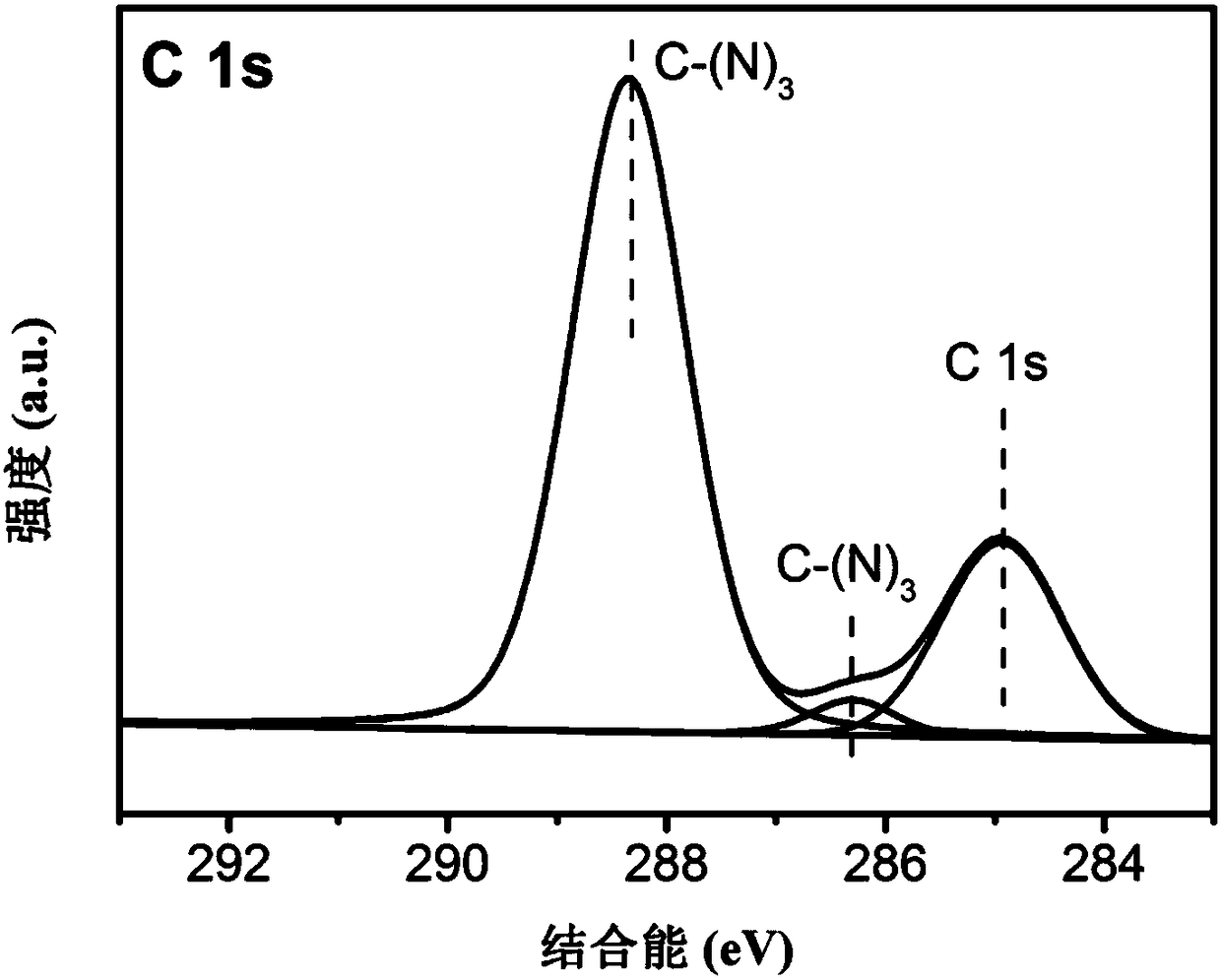

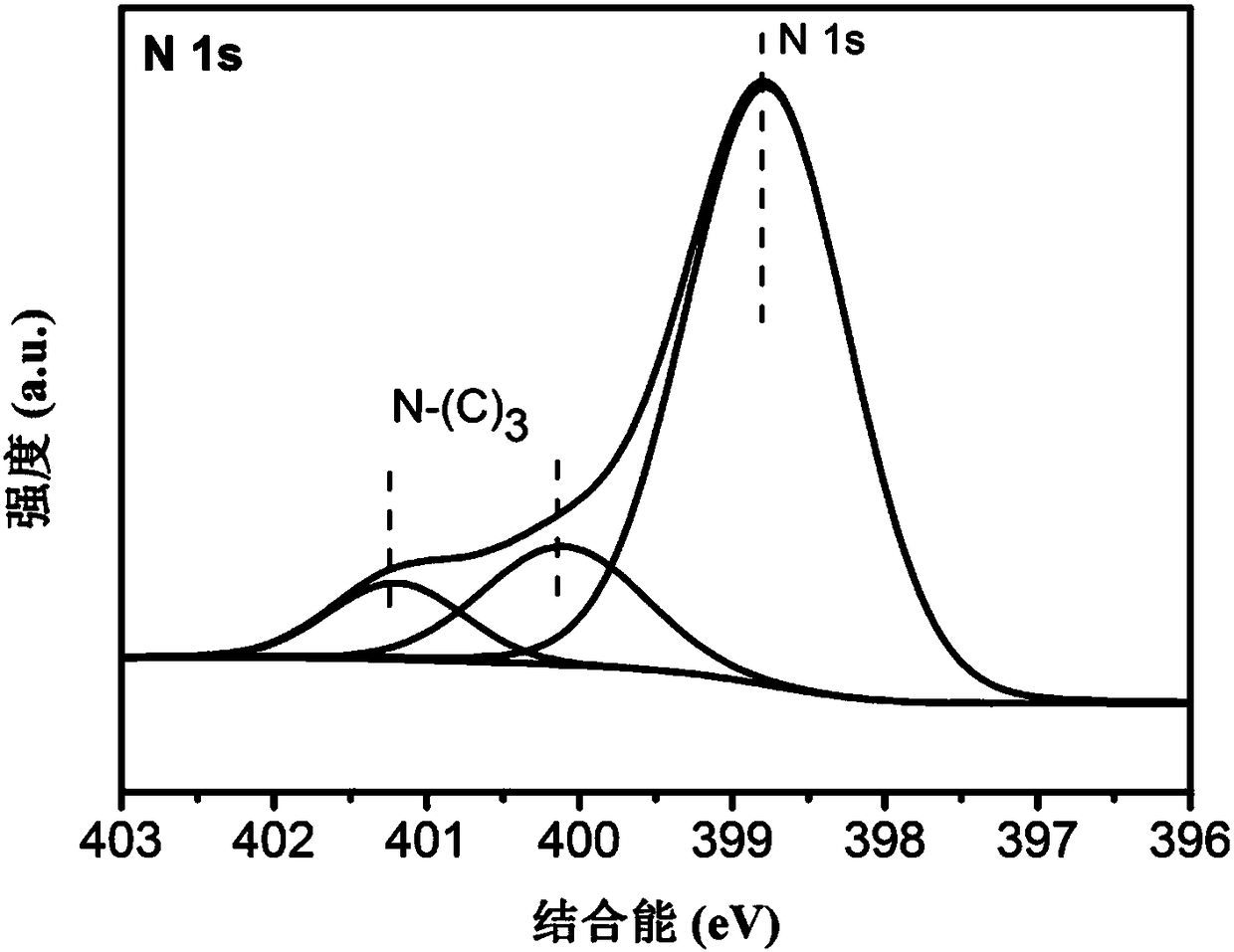

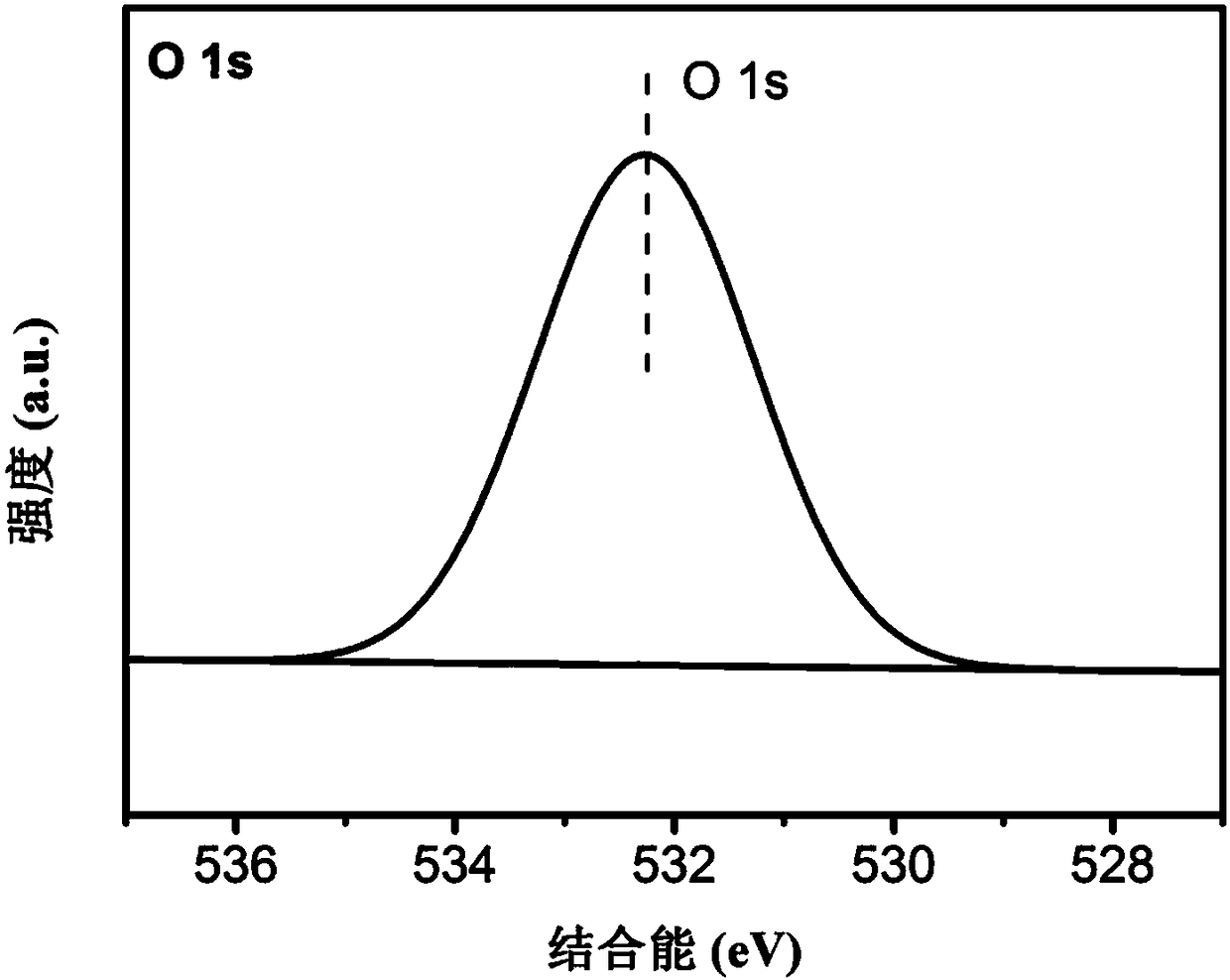

[0050] The photocatalyst prepared in embodiment 1 is carried out XPS, DRS, XRD etc. characterization, the result is as follows Figure 1 to Figure 8 shown.

[...

Embodiment 2

[0058] Put 10g of dicyandiamide in a crucible and cover it, calcined in a muffle furnace, the calcining temperature is 650°C, the holding time is 2 hours, and the heating rate is 5.0°C / min; after natural cooling, grind it into powder to obtain graphite phase nitrogen Carbonization (CN-D-1), weighed 1.2g, put it in a crucible without a cover, spread it out, and calcined again. The calcining temperature was 550°C, the holding time was 1 hour, and the heating rate was 10.0°C / min. After natural cooling, a high specific surface area carbon nitride photocatalyst (CN-D-2) was obtained. Weigh 0.01g of CN-D-2 in 100mL of water (about 100g), sonicate for 1 hour with an ultrasonic machine, and then centrifuge with a centrifuge to obtain a milky white suspension with a concentration of about 0.008wt% and a pH of about 6-7.

Embodiment 3

[0060] Put 10g of dicyandiamide in a crucible and cover it, calcined in a muffle furnace, the calcining temperature is 500°C, the holding time is 6 hours, and the heating rate is 1.0°C / min; after natural cooling, it is ground into powder to obtain graphite phase nitrogen Carbonization (CN-D-1), weighed 1.2g, put it in a crucible without a cover, spread it out, and calcined again. The calcining temperature was 450°C, the holding time was 4 hours, and the heating rate was 2.0°C / min. After natural cooling, a high specific surface area carbon nitride photocatalyst (CN-D-2) was obtained. Weigh 1g of CN-D-2 in 100mL of water (about 100g), use a ball mill to mill for 8 hours, and then let it stand to remove the precipitate to obtain a milky white suspension with a concentration of about 0.011wt% and a pH of about 6-7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com