Efficient grinding system for grinding machine

A high-efficiency and grinding technology, used in grain processing and other directions, can solve the problems of low grinding efficiency, poor toughness of low-chromium cast iron, and increased power consumption per unit product, so as to reduce grinding costs, improve grinding performance, and reduce operations. Effects of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

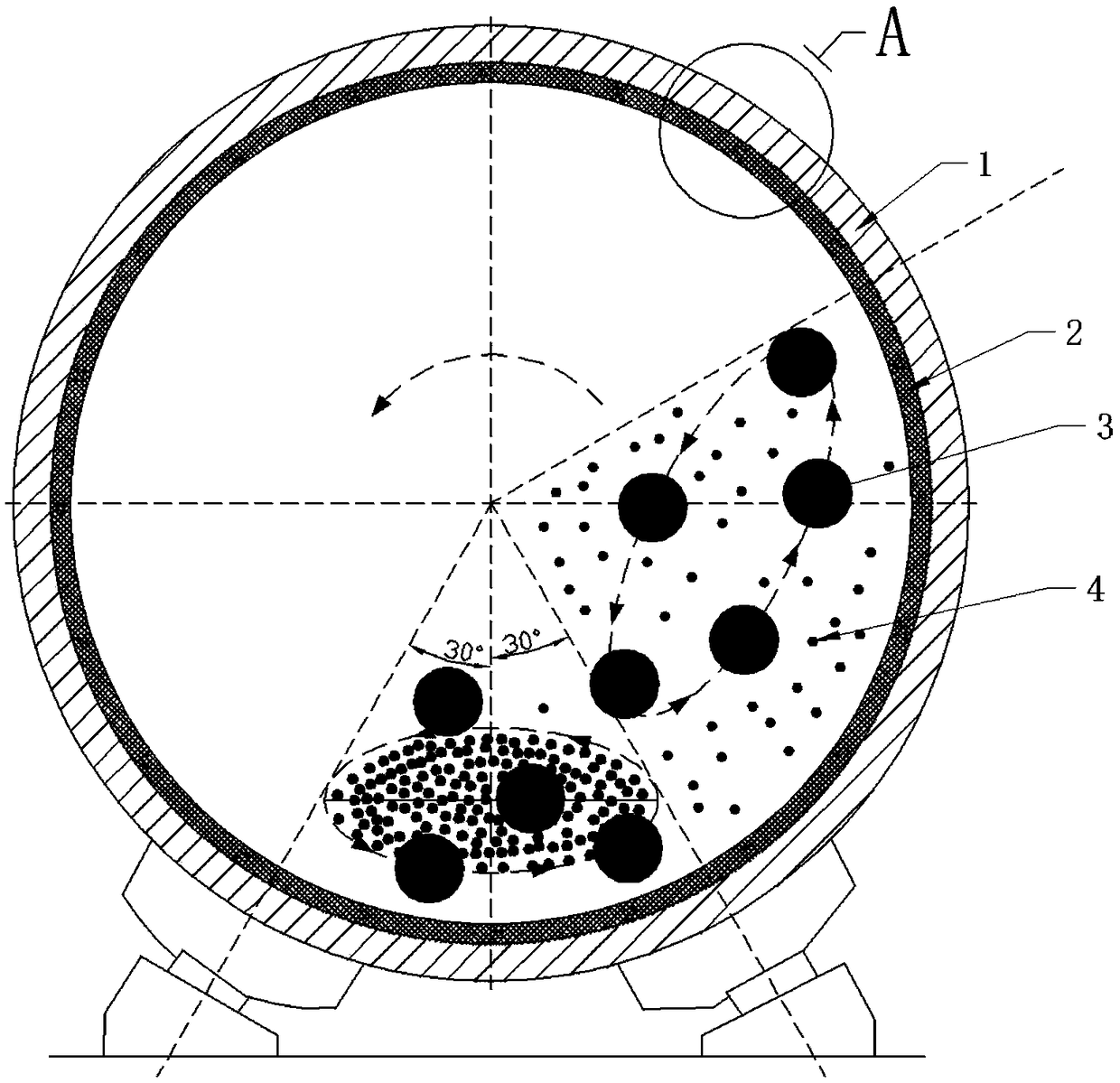

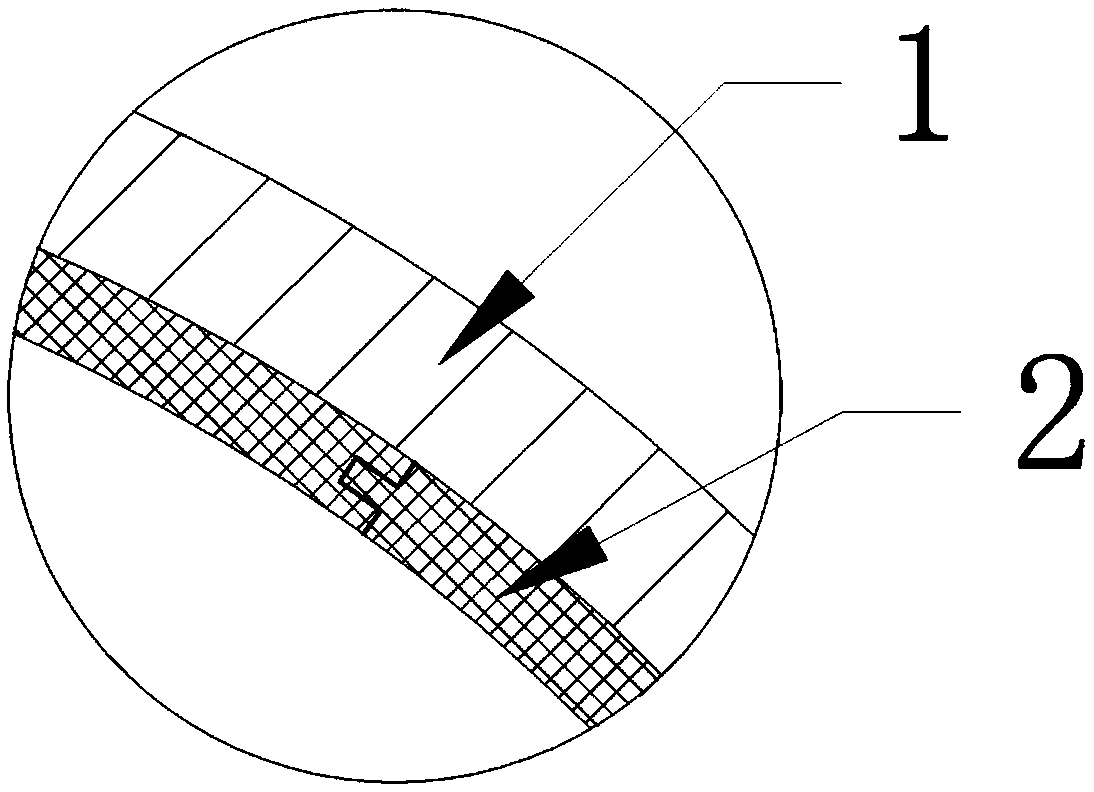

[0022] see figure 1 , figure 2 A high-efficiency grinding system for a mill. In this embodiment, the grinding system includes a grinding chamber 1 and a grinding body, wherein a layer of microcrystalline wear-resistant alumina liner 2 is formed inside the grinding chamber 1 The microcrystalline wear-resistant alumina liner 2 includes a liner unit, the liner unit is a curved veneer matching the arc surface of the grinding chamber cavity, and the adjacent liner units can be connected through the insertion groove structure. Disassemble and assemble, and form on the inner side of the grinding chamber cavity 1 by assembling.

[0023] In this example, the microcrystalline wear-resistant alumina liner has the characteristics of good wear resistance,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com