Preparation method of SAPO-56/SAPO-34 composite molecular sieve

A technology of SAPO-56 and SAPO-34, which is applied in the field of preparation of SAPO-56/SAPO-34 composite molecular sieves, can solve the problems of little MTO process research and SAPO-56 molecular sieve research, and achieve high solid phase yield , regular crystal form and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

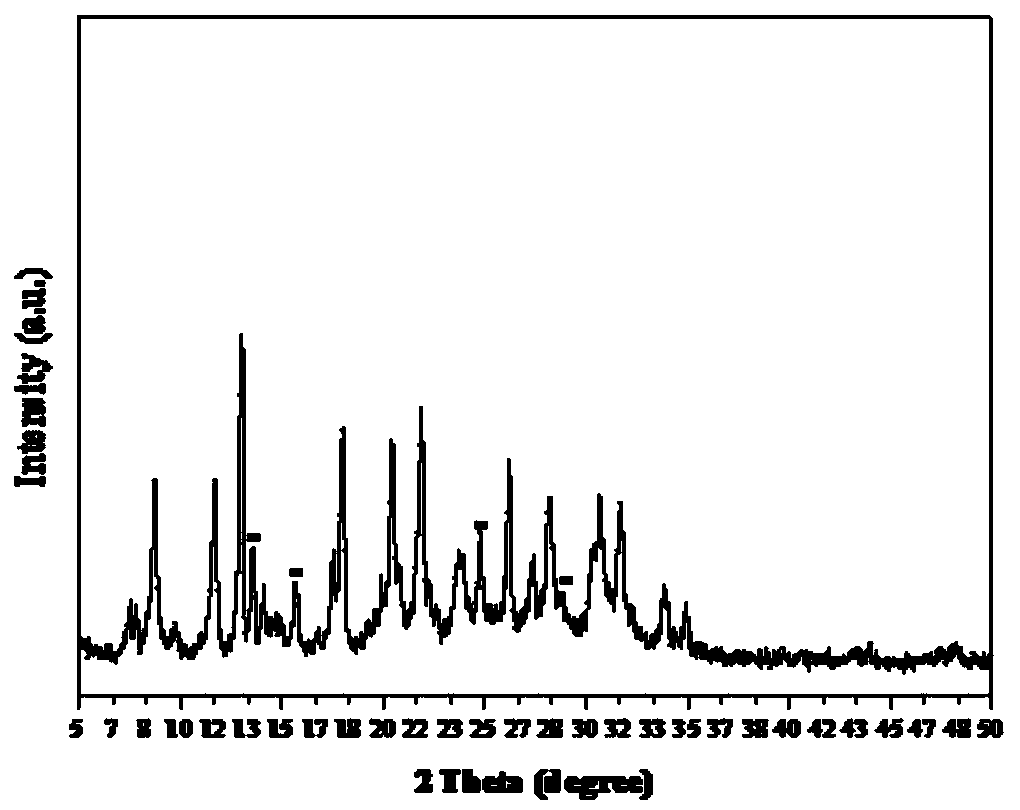

[0025] A preparation method for synthesizing SAPO-56 / SAPO-34 composite molecular sieves with N,N,N,N-tetramethyl-1,6-hexanediamine and triethylamine, the steps are as follows:

[0026] Step 1: N,N,N,N-Tetramethyl-1,6-hexanediamine and triethylamine are fully stirred and mixed to obtain a uniform mixed solution, and then added to the aqueous solution. The molar ratio of N,N,N,N-tetramethyl-1,6-hexanediamine to triethylamine was 8.

[0027] Step 2: Pseudoboehmite (Al 2 o 3 content is 75%) was added to the above homogeneous mixed solution, stirred at room temperature for 1 hour to obtain mixed solution A, and then weighed silica sol (SiO 2 content of 40%) was added to the mixed solution A, and stirred thoroughly for 1 hour to obtain the mixed solution B. In mixed solution B, the molar ratio of aluminum source and silicon source is SiO 2 :Al 2 o 3 =0.8.

[0028] Step 3: Add 5.77g of phosphoric acid dropwise into the mixed solution B, and stir well until a uniform gel mixtur...

Embodiment 2

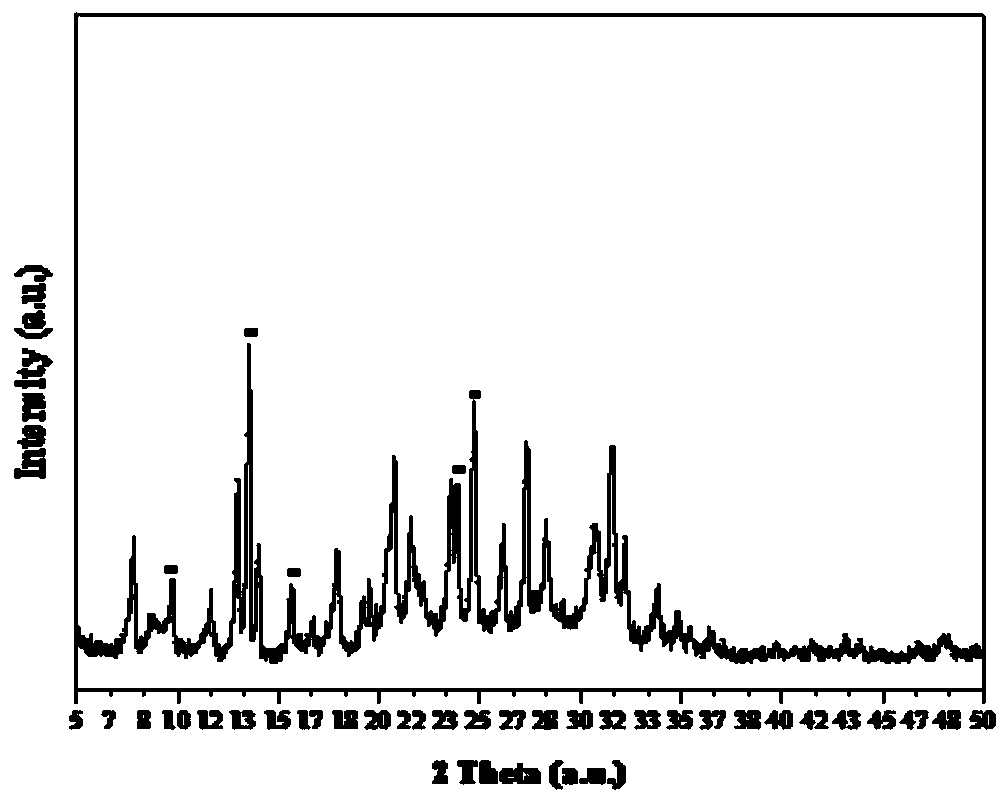

[0032] A kind of preparation method of synthetic SAPO-56 / SAPO-34 composite molecular sieve with N,N,N,N-tetramethyl-1,6-hexanediamine and triethylamine, the basic steps of its preparation are identical with embodiment 1 , the difference is: in step 1, the molar ratio of N,N,N,N-tetramethyl-1,6-hexanediamine and triethylamine is changed from 8 to 2, and finally SAPO-56 / SAPO- 34 composite molecular sieves, more SAPO-34 molecular sieves are formed, such as image 3 As shown in the XRD characterization results, its morphology changes to a square shape, such as Figure 4 SEM characterization picture shown.

Embodiment 3

[0034] A kind of preparation method of synthetic SAPO-56 / SAPO-34 composite molecular sieve with N,N,N,N-tetramethyl-1,6-hexanediamine and triethylamine, the basic steps of its preparation are identical with embodiment 1 , the difference is: in step 1, the molar ratio of N,N,N,N-tetramethyl-1,6-hexanediamine and triethylamine is changed from 8 to 0.8, and most of the obtained amorphous Gel-like substance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com