Gas-generating agent granules for air bags and pressing preparation method thereof

A technology of gas generating agent and preparation process, which is applied in the production of compressed gas, explosives, attack equipment, etc., can solve the problems of affecting the stability of generator products, unable to improve the strength of drug particles, and decreasing gas production, so as to avoid drug particles. The effect of reducing strength, avoiding a decrease in gas production, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

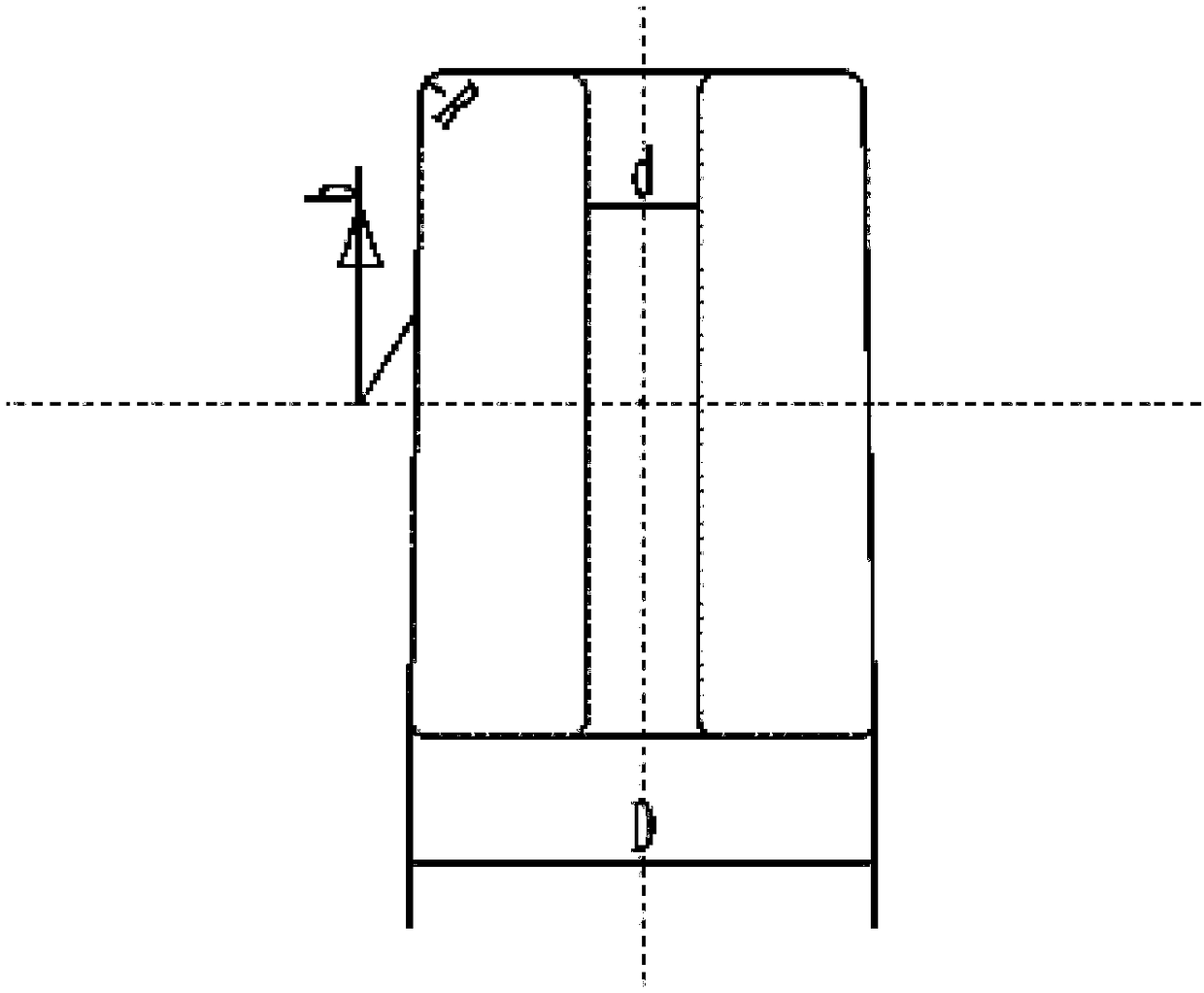

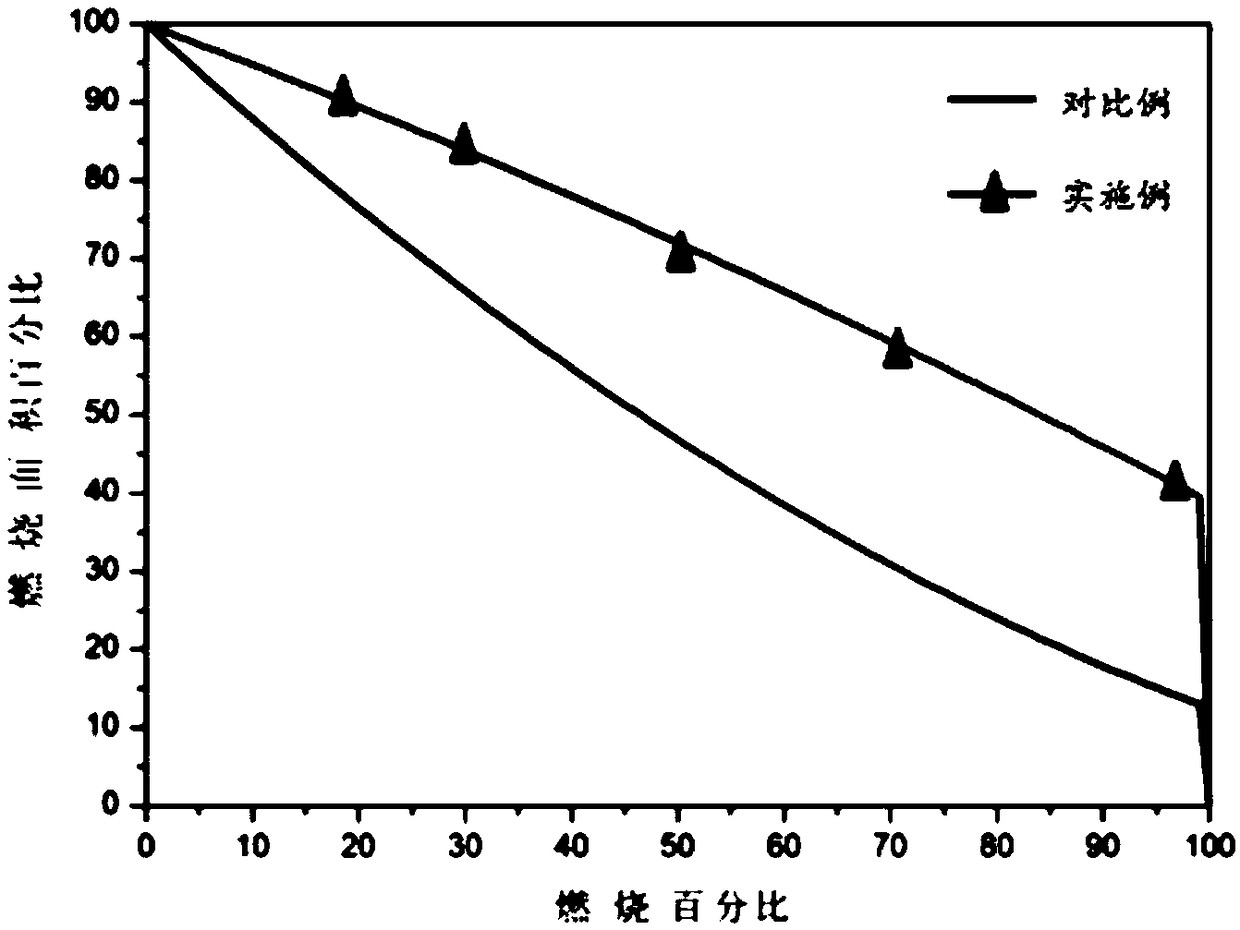

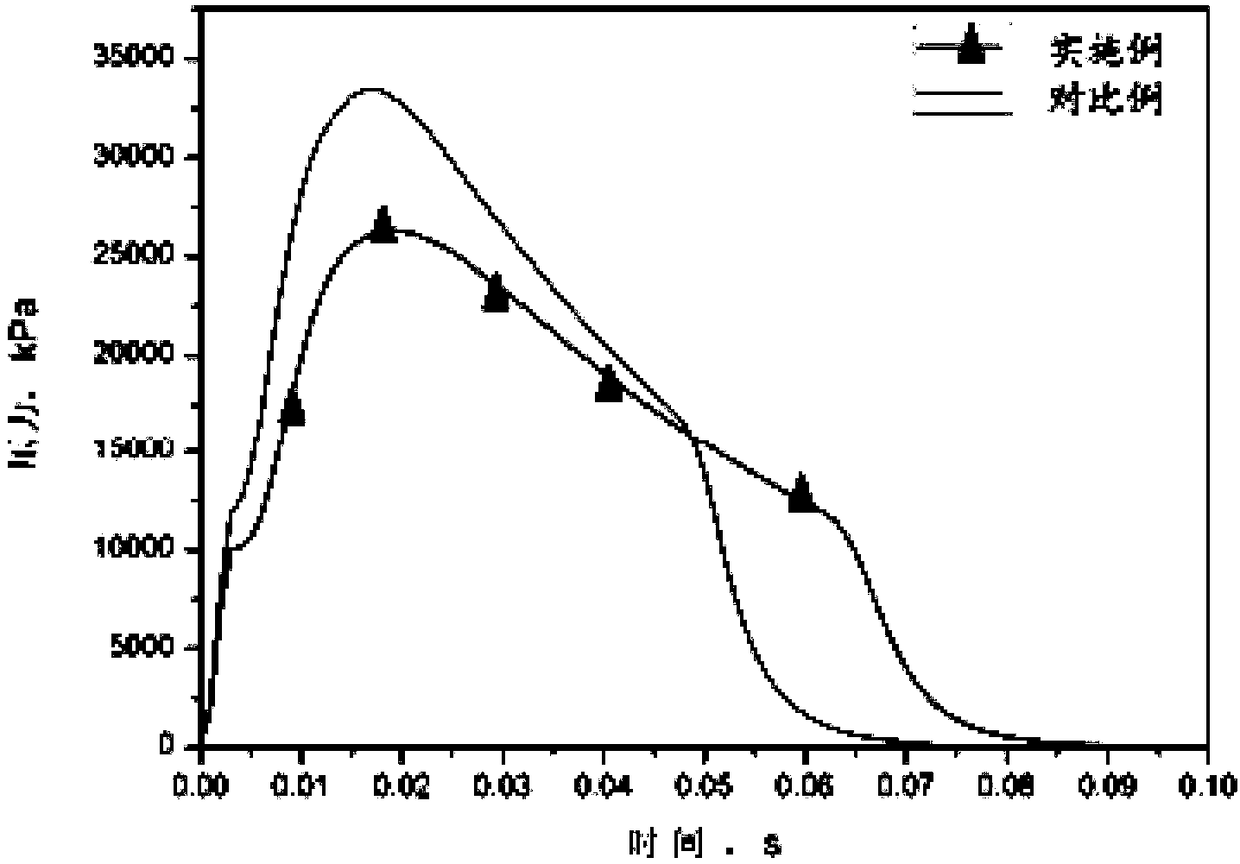

[0029] Take by weighing 52 kilograms of guanidine nitrate, 82.5 kilograms of basic copper nitrate with a solid content of 40%, 10 kilograms of ammonium perchlorate and 5 kilograms of copper oxide mixed and granulated, and then use a rotary tablet press to cooperate with a mold to compress into an outer diameter of 4mm, Gas generating agent pellets for frustum-shaped airbags with an inner diameter of 1mm, a height of 6mm, an edge fillet radius of 0.2mm, and a taper of 1:500; the schematic diagram of its shape and structure is as follows figure 1 shown. The prepared medicine pellets have high molding rate, high finish, good consistency of the whole batch of medicine pellets, and the gas production rate is 2.9mol / 100g.

[0030] Because tablets are prone to fragmentation, capping, rupture, etc. after being subjected to vibration or friction. Tablet friability reflects the anti-wear and vibration ability of the tablet, and is also an important item for tablet quality standard insp...

Embodiment 2

[0034] Weigh 37 kilograms of guanidine nitrate, 41 kilograms of dried basic copper nitrate, 10 kilograms of strontium nitrate, 9 kilograms of pentaaminotetrazole, 2 kilograms of ammonium perchlorate and 1 kilogram of iron oxide and mix and granulate them for use The rotary tablet press was pressed into frustum-shaped gas generating agent pellets for airbags with an outer diameter of 5.5 mm, an inner diameter of 1.5 mm, a height of 6 mm, a taper of 1:500, and a rounded edge with a radius of 0.5 mm. The gas production rate was 2.77 mol / 100 g.

[0035] It was tested by a brittle instrument, and the weight loss was determined to be 0.3%, and the lateral compressive strength was measured to be 120N by a hardness tester.

Embodiment 3

[0037] Take by weighing 25 kilograms of guanidine nitrate, 83 kilograms of basic copper nitrate with a solid content of 52%, 26 kilograms of guanidinyl urea copper nitrate, 4 kilograms of iron oxide and 2 kilograms of potassium perchlorate spray granules and dry and press to make the outer diameter 5.5mm, inner diameter 1.5mm, height 6mm, taper 1:500 frustum-shaped gas generating agent for airbags with right-angled edges, the gas production rate is 2.64mol / 100g.

[0038] It was tested with a brittle instrument, and the weight loss was determined to be 0.9%, and the lateral compressive strength was measured to be 120N using a tablet hardness tester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com