A preparation process of tin-based babbitt alloy coating material based on 3D printing technology

A tin-based babbitt alloy, 3D printing technology, applied in metal material coating process, coating, additive processing, etc., can solve the problems of material waste, large particle size, low atomization efficiency, etc., and achieve controllable particle size Sexual enhancement, uniform tissue refinement, and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Add antimony and copper into the vacuum melting chamber, evacuate to 0.5Pa, first raise the temperature to 800°C at a rate of 5°C / min, and keep warm for 5 minutes, then raise the temperature to 1050°C at a rate of 1°C / min, and keep warm After complete melting, lower the temperature to 800°C, add tin and continue to stir evenly, then raise the temperature to 900°C at a rate of 1°C / min, add bismuth, lead and cadmium, stir at 8000r / min at a high speed, and solidify to obtain ZSnSb11Cu6 tin-based Babbitt alloy ingot, wherein the mass percentage of the components in the tin-based Babbitt alloy ingot is: Sn balance, Cu 5.5-6.5, Sb10.0-12.0, Fe≤0.1, Zn≤0.01, Bi≤0.03, As ≤0.1, Al≤0.01, Pb≤0.35, Cd≤0.35, other elements ≤0.55.

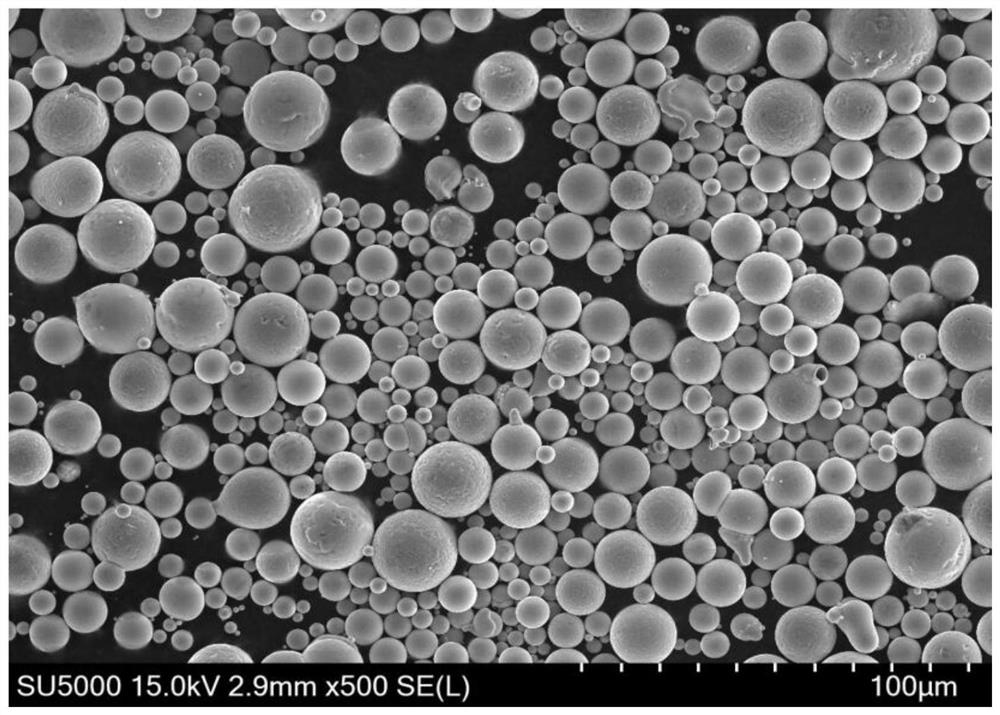

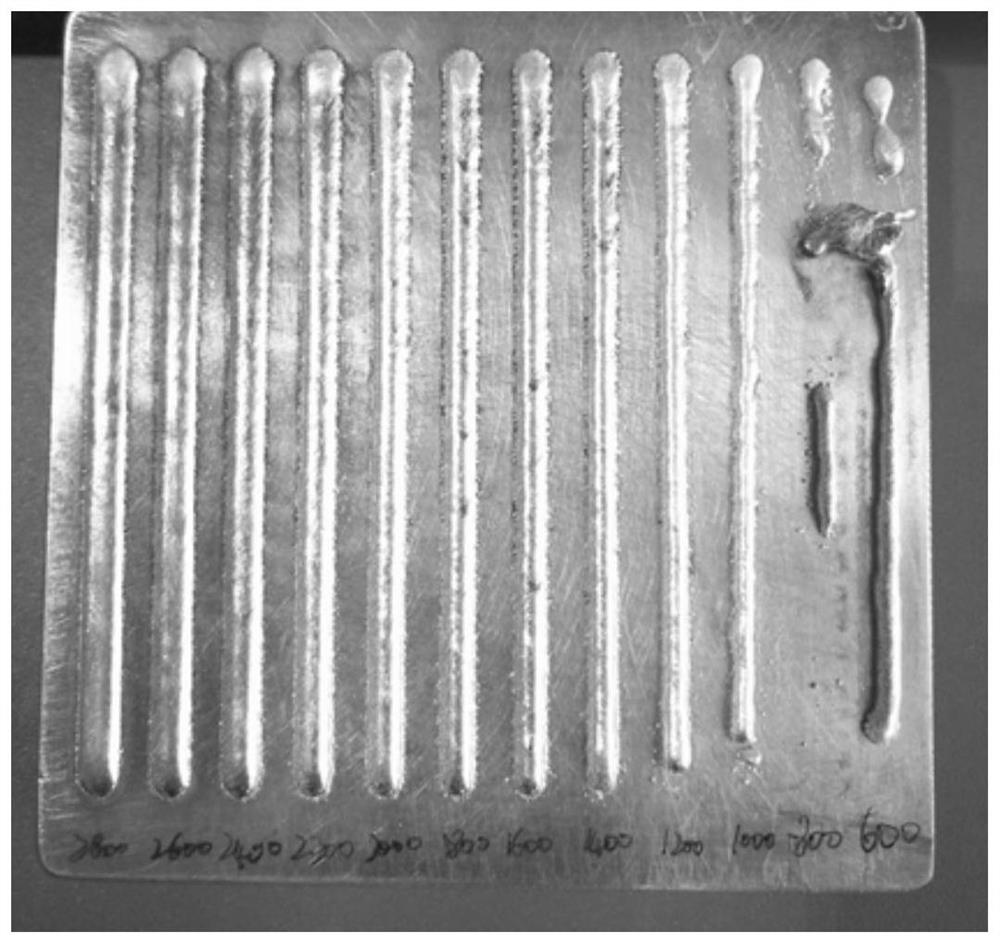

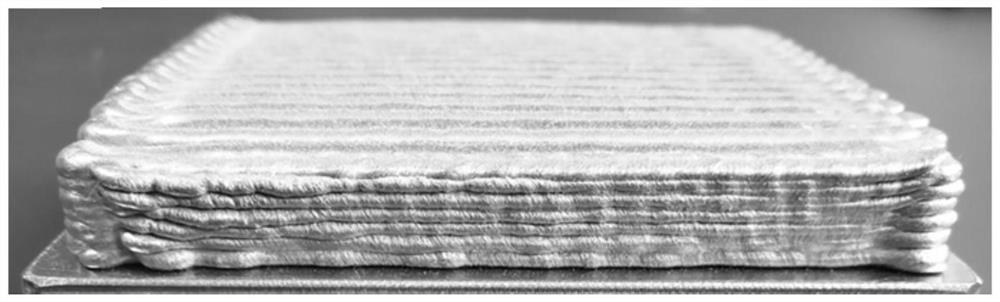

[0042] (2) The tin-based Babbitt alloy ingot flows downward from the diversion nozzle, and passes through the secondary laminar flow injection system composed of the restricted nozzle and the close-coupled nozzle. Under the working pressure of 2MPa, t...

Embodiment 2

[0047] (1) Add antimony and copper into the vacuum melting chamber, pump the vacuum to 3Pa, first raise the temperature to 850°C at a rate of 10°C / min, keep it warm for 10 minutes, then raise the temperature to 1250°C at a rate of 3°C / min, and keep it warm until After complete melting, lower the temperature to 850°C, add tin and continue to stir evenly, then raise the temperature to 950°C at a rate of 5°C / min, add bismuth, lead and cadmium, stir at a high speed of 12000r / min, and solidify to obtain ZSnSb11Cu6 tin base bar Babbitt alloy ingot, wherein the mass percentage of the components in the tin-based babbitt alloy ingot is: Sn balance, Cu 5.5-6.5, Sb10.0-12.0, Fe≤0.1, Zn≤0.01, Bi≤0.03, As≤ 0.1, Al≤0.01, Pb≤0.35, Cd≤0.35, other elements≤0.55.

[0048] (2) The tin-based Babbitt alloy ingot flows downward from the diversion nozzle, and through the secondary laminar flow injection system composed of the restricted nozzle and the close-coupled nozzle, under the working pressure...

Embodiment 3

[0053](1) Add antimony and copper into the vacuum melting chamber, evacuate to 1.5Pa, first raise the temperature to 830°C at a rate of 6°C / min, keep it warm for 6 minutes, then raise the temperature to 1150°C at a rate of 1.5°C / min, and keep warm After complete melting, lower the temperature to 830°C, add tin and continue to stir evenly, then raise the temperature to 920°C at a rate of 3°C / min, add bismuth, lead and cadmium, stir at a high speed of 10000r / min, and solidify to obtain ZSnSb11Cu6 tin-based Babbitt alloy ingot, wherein the mass percentage of the components in the tin-based Babbitt alloy ingot is: Sn balance, Cu 5.5-6.5, Sb10.0-12.0, Fe≤0.1, Zn≤0.01, Bi≤0.03, As ≤0.1, Al≤0.01, Pb≤0.35, Cd≤0.35, other elements ≤0.55.

[0054] (2) The tin-based Babbitt alloy ingot flows downward from the diversion nozzle, and passes through the secondary laminar flow injection system composed of the restricted nozzle and the close-coupled nozzle. Under the working pressure of 4MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com