Pulping method of high-yield coniferous wood dissolving pulp and dissolving pulp prepared by pulping method

A technology for coniferous wood and dissolving pulp, which is applied in the direction of pulping with inorganic alkali, pulp bleaching, digester, etc., can solve the problems of scaling on the inner wall of hydrolysis equipment, increase in cost, etc., so as to improve the risk resistance ability, easy operation, and increase products. The effect of diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

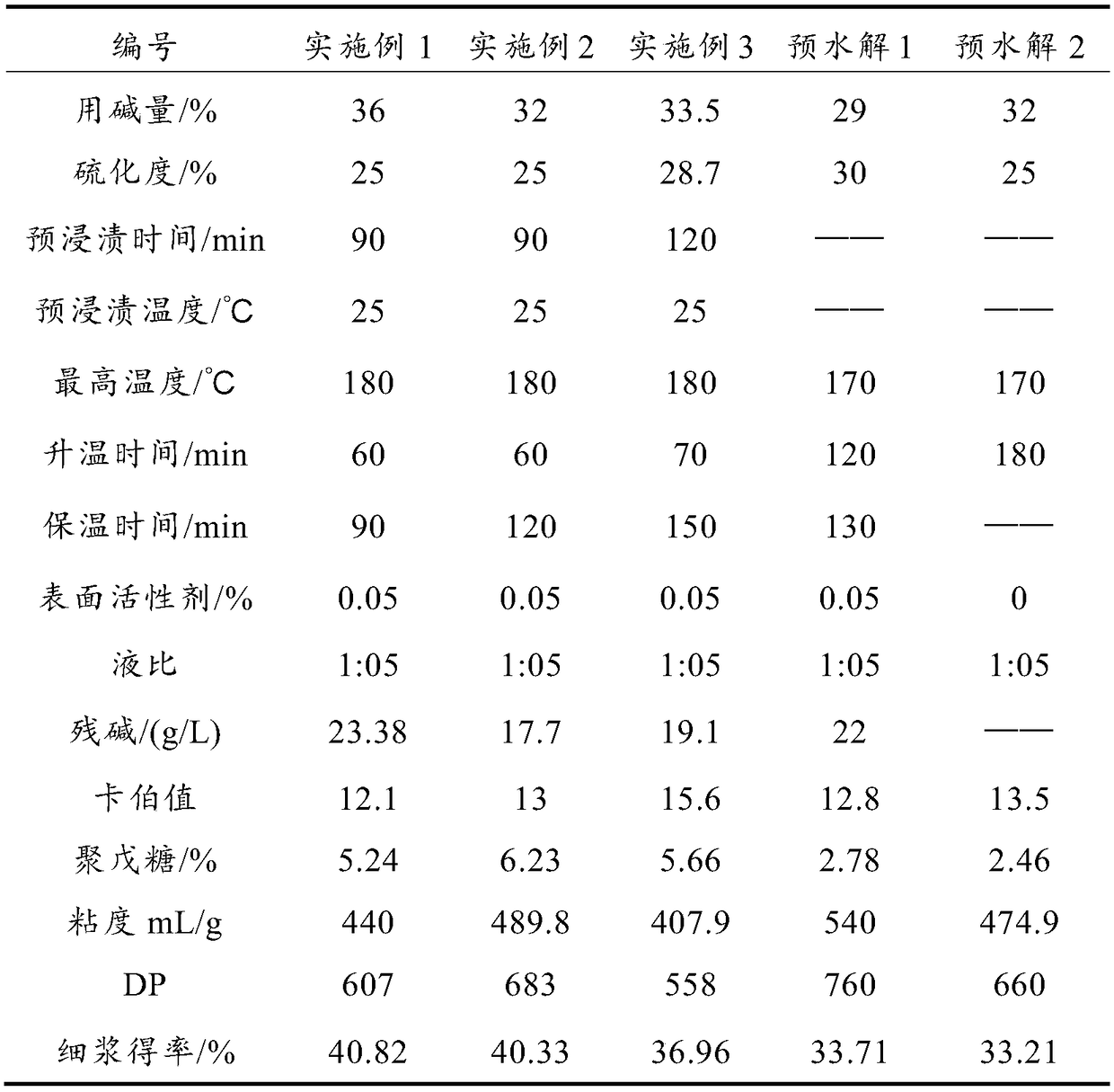

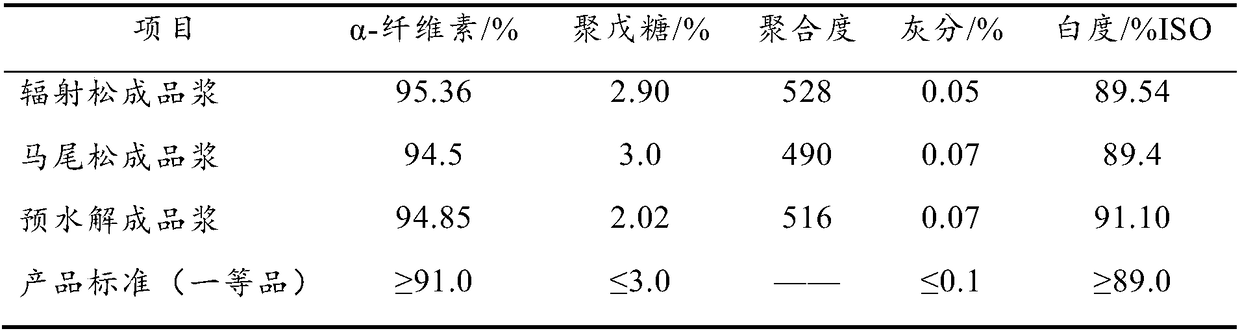

Embodiment 1

[0033] The present embodiment takes radiata pine as the research object, and the pulping method of the high-yield softwood dissolving pulp provided comprises the following steps carried out in order:

[0034] Kraft cooking steps:

[0035] 1) Remove the knots from the radiata pine log, peel it, cut it into 15-30mm long and 3-5mm thick wood chips, air-dry and mix well, then balance the moisture for subsequent cooking;

[0036] 2) The cooking liquid is prepared and mixed with wood chips; wherein, the cooking liquid is a mixed solution of sodium hydroxide, sodium sulfide, sodium dodecylbenzenesulfonate and water.

[0037] 3) Low-temperature pre-impregnation: put the wood chips and cooking liquid into the digester, and perform pre-impregnation at a temperature of 25°C. The amount of alkali used is 36% (NaOH), the degree of sulfide is 25%, and the liquid ratio is 1:5. The dosage of sodium dialkylbenzene sulfonate is 0.05%, and it is pre-impregnated for 90 minutes to make half mater...

Embodiment 2

[0040] The present embodiment takes radiata pine as the research object, and the pulping method of the high-yield radiata pine dissolving pulp provided comprises the following steps carried out in order:

[0041] Kraft cooking steps:

[0042] 1) Remove the knots from the radiata pine log, peel it, cut it into 15-30mm long and 3-5mm thick wood chips, air-dry and mix well, then balance the moisture for subsequent cooking;

[0043] 2) mixing the prepared cooking liquid with wood chips; wherein, the cooking liquid is a mixed solution of sodium hydroxide, sodium sulfide, sodium dodecylbenzenesulfonate and water.

[0044] 3) Low-temperature pre-impregnation: put the wood chips and cooking liquid into the digester, and perform pre-impregnation at a temperature of 25°C. The amount of alkali used is 32% (calculated by NaOH), and the degree of sulfide is 25%; the liquid ratio is 1:5, ten The dosage of sodium dialkylbenzene sulfonate is 0.05%, and it is pre-impregnated for 90 minutes to...

Embodiment 3

[0047] The present embodiment takes Masson pine as the research object, and the pulping method of the high-yield softwood dissolving pulp provided comprises the following steps carried out in order:

[0048] Kraft cooking steps:

[0049] 1) Remove the knots from the masson pine log, peel it, cut it into 15-30mm long and 3-5mm thick wood chips, air-dry and mix well, balance the water, and prepare for subsequent cooking;

[0050] 2) The cooking liquid is prepared and mixed with wood chips; wherein, the cooking liquid is a mixed solution of sodium hydroxide, sodium sulfide, sodium dodecylbenzenesulfonate and water.

[0051] 3) Low-temperature pre-impregnation: put the wood chips and cooking liquid into the digester, and perform pre-impregnation at a temperature of 25°C. The amount of alkali used is 32% (calculated by NaOH), and the degree of sulfide is 25%; the liquid ratio is 1:5, ten The dosage of sodium dialkylbenzene sulfonate is 0.05%, and it is pre-soaked for 120 minutes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com