Preparation method of polyvinyl chloride-based polymer electrolyte membrane

A polyvinyl chloride, electrolyte membrane technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of high voltage, high specific energy, low self-discharge rate, etc., to achieve enhanced wear resistance and impact resistance, The effect of low raw material cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

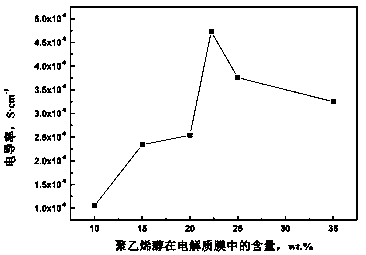

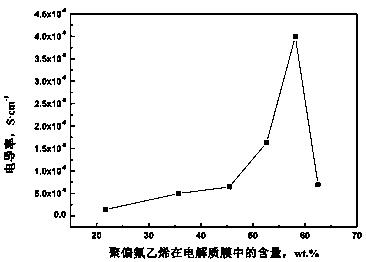

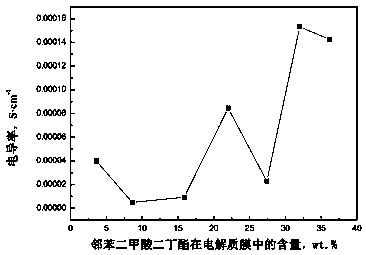

Image

Examples

specific Embodiment approach 1

[0016] Embodiment 1: A method for preparing a polyvinyl chloride-based polymer electrolyte membrane according to this embodiment is prepared according to the following steps:

[0017] 1. Weigh polyvinyl chloride and polyvinyl alcohol into a reaction vessel, add 4-6ml of solvent, stir well to dissolve the polymer completely, then add plasticizer dibutyl phthalate, and keep stirring for about 1 hour;

[0018] 2. Weigh polyvinylidene fluoride, add polyvinylidene fluoride and 4-6ml solvent into another reaction vessel, stir to dissolve polyvinylidene fluoride completely, and mix with polyvinyl alcohol, polyvinyl chloride and phthalic acid Dibutyl ester was blended, stirred evenly, lithium salt was added, stirred for 5 hours, the mixture was cast on a glass plate, placed in a vacuum drying oven, and dried at 120° C. for 1 hour to obtain a polymer electrolyte membrane.

[0019] Specific implementation measures two: the difference between this embodiment and specific embodiment one i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com