Synthesis method of trinonyl benzene-1,2,4-tricarboxylate plasticizer

A technology of triisononyl trimellitate and a synthesis method, which is applied in the field of synthesizing triisononyl trimellitate plasticizers, and can solve the problems of phthalate dissolution, strong volatility and migration, etc. problems, to achieve the effect of easy control of process conditions, stable quality and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

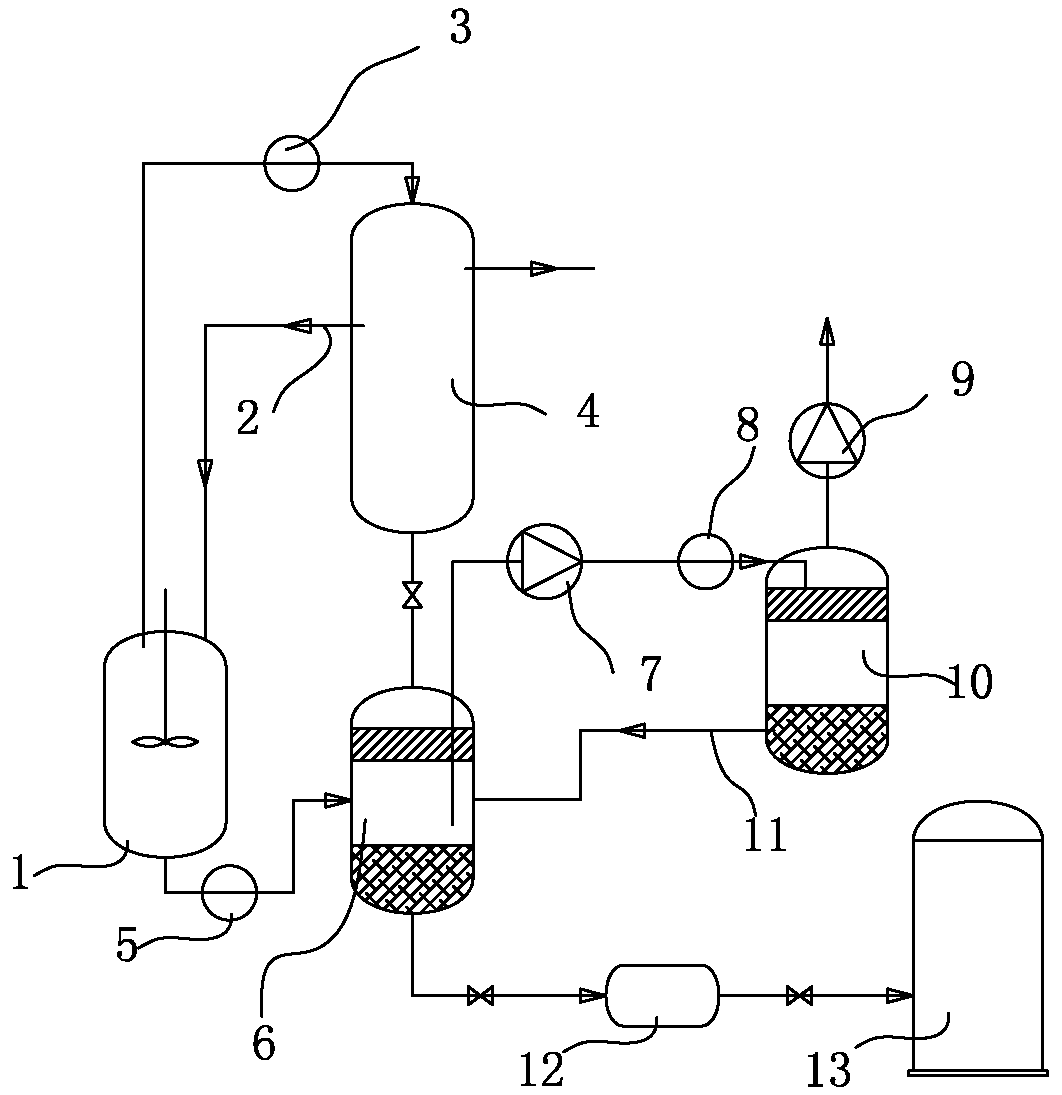

[0023] Such as figure 1 As shown, it is a device for the synthesis of triisononyl trimellitate plasticizer, including an esterification reactor 1, and the gas phase outlet at the top of the esterification reactor 1 is connected to the alcohol-water separation tower through a heat exchanger 3 4. The top, and the middle part of the alcohol-water separation tower 4 is provided with a reflux pipe—2 connected to the esterification reactor 1; the bottom of the esterification reactor 1 is connected to the dealcoholization tower 7, and the bottom of the dealcoholization tower 7 is connected to the finished product tank 13 through a filter 12; The dealcoholization tower 7 is connected with a dealcoholization reflux device, which includes a rectification tower 10, and the dealcoholization tower 7 is connected to the rectification tower 10 through a circulating pump 7 and a heat exchanger 38, and the rectification tower 10 A vacuum pump 9 is connected to it, and the reflux tank 2 11 at t...

Embodiment 2

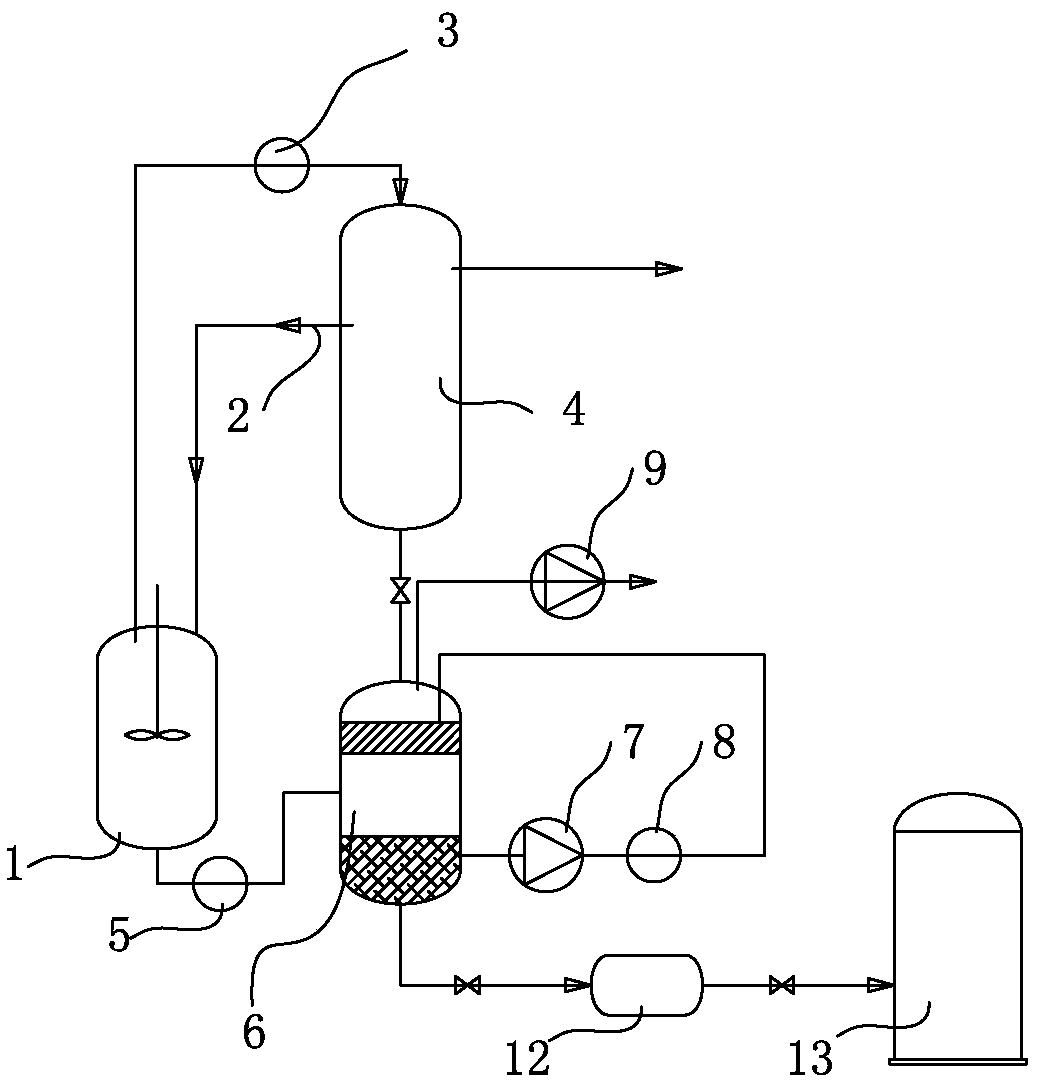

[0031] Such as figure 2 As shown, it is another device used for the synthesis of triisononyl trimellitate plasticizer, including an esterification reactor 1, and the gas phase outlet at the top of the esterification reactor 1 is connected to the alcohol-water separation through a heat exchanger 3 The top of the tower 4 and the middle part of the alcohol-water separation tower 4 are provided with a reflux pipe-2 connected to the esterification reactor 1; the bottom of the esterification reactor 1 is connected to the dealcoholization tower 7, and the bottom of the dealcoholization tower 7 is connected to the finished product tank 13 through a filter 12 ; The dealcoholization tower 7 is connected with a dealcoholization reflux device, which includes a vacuum pump 9, a circulation pump 7, a heat exchanger three 8, and the dealcoholization tower 7 passes through the circulation pump 7, the heat exchanger three 8 Since the circulation is connected, the vacuum pump 9 is connected at...

Embodiment 3

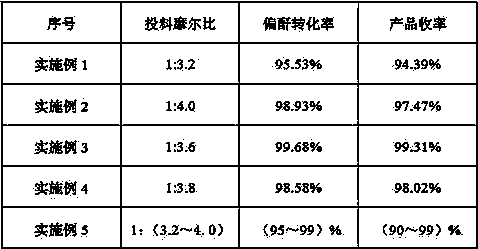

[0039] A kind of synthetic method of triisononyl trimellitate plasticizer comprises the following steps successively:

[0040] S1, esterification reaction: the content of anhydride in the raw material trimellitic anhydride ≥ 98%; the purity of the raw material isononyl alcohol ≥ 99%; the raw material trimellitic anhydride and isononyl alcohol are put into the esterification reaction kettle 1, under the condition of nitrogen protection and uniform stirring , heated to 135-155°C, the molar ratio of trimellitic anhydride to isononanol is 1:3.6; after trimellitic anhydride is completely dissolved in isononanol, then the temperature is raised to 180°C, and a catalyst is added, the catalyst is tetrapropylene titanate Ester and tetraisopropyl titanate are compounded at a mass ratio of 1:2, and the amount of catalyst is 0.08% of the total mass of the reaction raw materials; heat preservation reaction for 1 hour, and the water generated during the esterification process is separated; co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com