A kind of methanol gasoline additive and preparation method thereof

A technology of methanol gasoline and additives, which is applied in the direction of fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of methanol gasoline encountering water, stratification, metal corrosion performance, etc., and achieves reduction of soot, high production efficiency, and effective Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

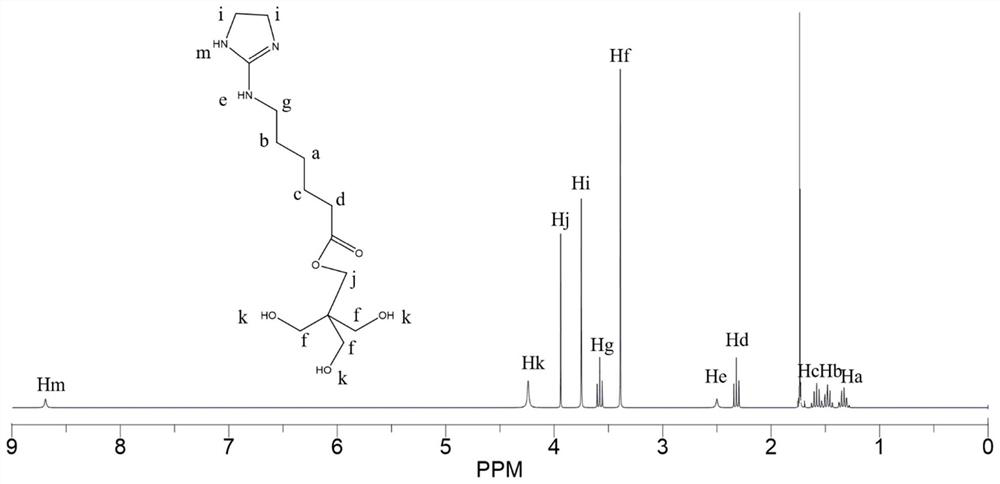

[0036] (1) Add 1.36kg of raw material pentaerythritol and 13.6L of toluene into the reaction vessel, raise the temperature to 65°C, after the pentaerythritol dissolves, add 30g of catalyst concentrated sulfuric acid, and continue to stir and mix evenly under nitrogen gas protection;

[0037] (2) Weigh 1.59kg of 6-(4-5-dihydro-1H-imidazole-2-amino)-hexanoic acid, dilute and mix with 8L of toluene;

[0038] (3) set up the reaction device, under the nitrogen gas protection condition, increase the step (1) system temperature, until the system starts to reflux, then add the solution of the step (2) dropwise in the step (1) device, and control the rate of addition to be 10 drops / min, continue to reflux for 48 hours after the dropwise addition, and measure the esterification rate of the reaction system to be 88%;

[0039] (4) After the reaction finishes, cool to room temperature, wash with saturated sodium bicarbonate water 3-5 times, then wash 3-5 times with deionized water, remove ...

Embodiment 2

[0044] (1) Add 1.36kg of raw material pentaerythritol and 16.3L of xylene into the reaction vessel, heat up to 60°C, after the pentaerythritol is dissolved, add 70.8g of catalyst p-toluenesulfonic acid, and continue to stir and mix evenly under nitrogen gas protection;

[0045] (2) Weigh 1kg of 6-(4-5-dihydro-1H-imidazole-2-amino)-hexanoic acid, dilute and mix with 6.5L xylene;

[0046] (3) set up the reaction device, under the nitrogen gas protection condition, increase the step (1) system temperature, until the system starts to reflux, then add the solution of the step (2) dropwise in the step (1) device, and control the rate of addition to be 12 drops / min, continue to reflux for 44 hours after the dropwise addition, and measure the esterification rate of the reaction system to be 85%;

[0047] (4) After the reaction finishes, cool to room temperature, wash with saturated sodium bicarbonate water 3-5 times, then wash 3-5 times with deionized water, remove trace water in the oi...

Embodiment 3

[0049] (1) 1.36kg of raw material pentaerythritol and 20.4LN'N-dimethylformamide were added to the reaction vessel, the temperature was raised to 70°C, after the pentaerythritol was dissolved, 167.5g of catalyst methanesulfonic acid was added, under the protection condition of helium gas, Continue to stir to mix well;

[0050] (2) Weigh 1.99kg of 6-(4-5-dihydro-1H-imidazole-2-amino)-hexanoic acid, dilute and mix with 15.9L of N'N-dimethylformamide;

[0051] (3) set up the reaction device, under the protection condition of helium gas, increase the temperature of the step (1) system until the system starts to reflux, then add the solution of the step (2) dropwise to the device of the step (1), and control the rate of addition It was 10 drops / min, and the reflux reaction was continued for 40h after the dropwise addition, and the esterification rate of the reaction system was determined to be 92%;

[0052] (4) After the reaction finishes, cool to room temperature, wash with satur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com