Dust granulation-leaching-residual oil removal process for oil-tea camellia cakes

A technology for camellia cake and dust is applied in the field of camellia cake dust granulation and leaching to remove residual oil. The effect of reducing dosage and improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The process of oil tea cake dust granulation and leaching to remove residual oil includes the following steps:

[0029] (1) placing the camellia oleifera cake in a vacuum low-temperature cold air dryer, and drying at 32-35°C until the moisture content of the camellia oleifera cake is 25%-27%;

[0030] (2) Pulverize the camellia oleifera cake, pass through a 30-mesh sieve to obtain tea-oil tea cake powder, send the camellia oleifera cake powder into the microwave processing equipment, and microwave at intervals at a microwave frequency of 2450MHz and a power of 500W, the interval time is 5min, each microwave Treat for 10 minutes, 3 times in a row;

[0031] (3) the camellia oleifera cake powder after the microwave treatment is passed through a granulator, the compression ratio of the granulator is 1:7, the granulation diameter is 6mm, and the granulation length is 8mm;

[0032] (4) put the camellia oleifera cake particles in step 3 into an organic solvent and soak for 2....

Embodiment 2

[0038] The process of oil tea cake dust granulation and leaching to remove residual oil includes the following steps:

[0039] (1) placing the camellia oleifera cake in a vacuum low-temperature cold air dryer, and drying at 32-35°C until the moisture content of the camellia oleifera cake is 25%-27%;

[0040] (2) Pulverize the camellia oleifera cake, pass through a 30-mesh sieve to obtain tea-oil tea cake powder, send the camellia oleifera cake powder into the microwave processing equipment, and microwave at intervals at a microwave frequency of 2450MHz and a power of 500W, the interval time is 5min, each microwave Treat for 10 minutes, 3 times in a row;

[0041] (3) the camellia oleifera cake powder after the microwave treatment is passed through a granulator, the compression ratio of the granulator is 1:7, the granulation diameter is 6mm, and the granulation length is 8mm;

[0042] (4) put the camellia oleifera cake particles in step 3 into an organic solvent and soak for 2....

Embodiment 3

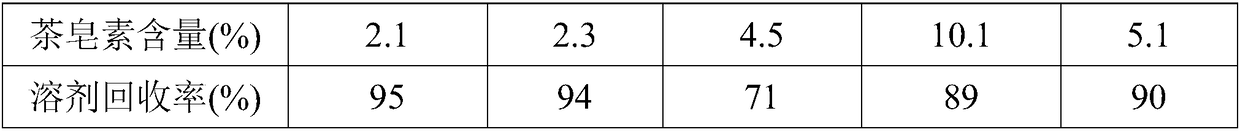

[0078] Based on Example 1, a comparative example 1 in which glycerin formal is not added to the organic solvent, a comparative example 2 in which DM130 macroporous adsorption resin is used, and a comparative example 3 in which a flash dryer is used to dry are set.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com