A kind of preparation method of imidazole dialkyl phosphate ionic liquid

A technology of azole-type dialkyl phosphate and dialkyl phosphate, which is applied in the field of ionic liquid preparation, can solve the impossibility of ionic liquid in the chemical industry, restrict the large-scale production of ionic liquid, and difficult to remove impurity ions, etc. problems, to achieve huge industrial application potential, easy control of the preparation process, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

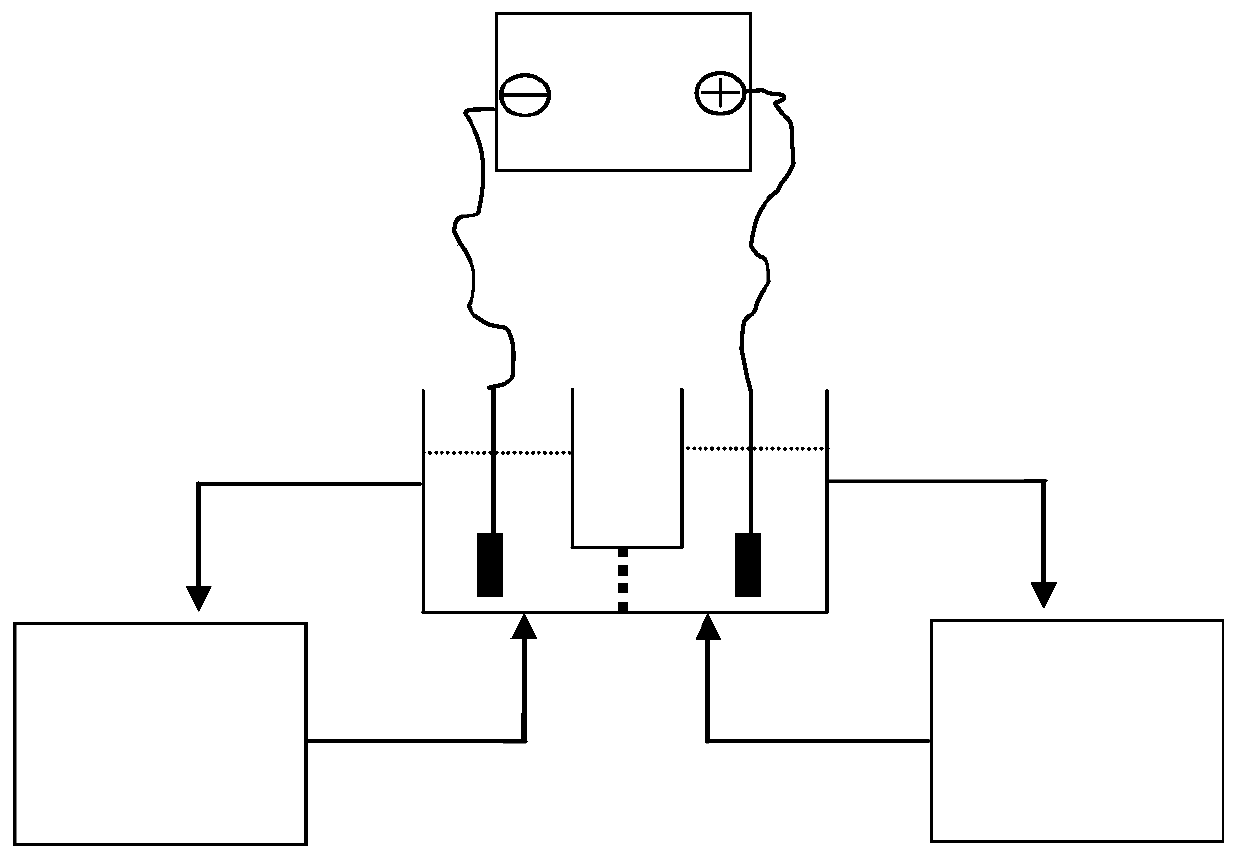

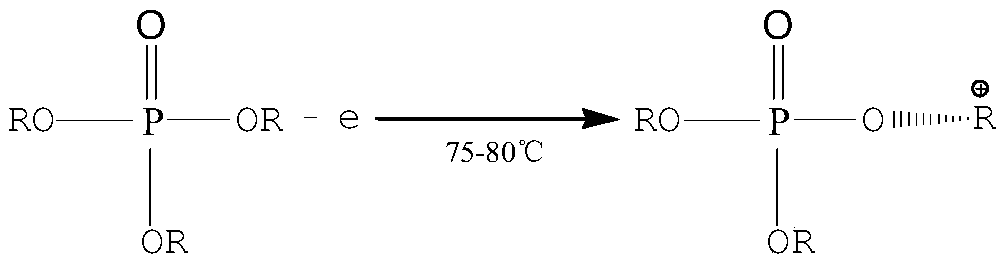

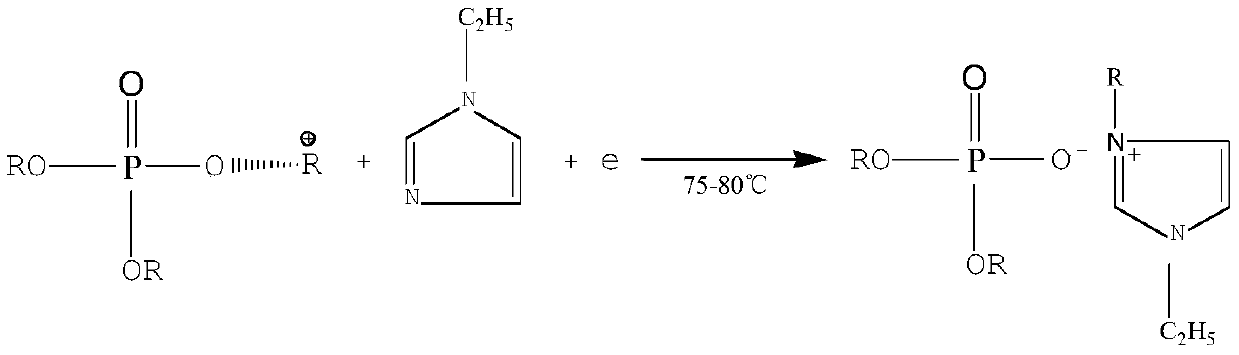

[0024] A method for preparing an imidazole dialkyl phosphate ionic liquid. Electrolysis is carried out in an electrolytic cell including a cathode chamber and an anode chamber. A layer of perfluorinated cation exchange membrane is also arranged between the cathode chamber and the anode chamber. The stable anode is the anode, and Pt is the cathode. The acetonitrile solution of N-ethylimidazole with a concentration of 1.2mol / L is added in the cathode chamber, and the acetonitrile solution of trimethyl phosphate with a concentration of 1.6mol / L is added in the anode chamber. Silicon-through rectifier power supply, the electrolysis temperature is 75°C, and the current density is 2.5A / dm 2 Under the conditions of electrolysis for 6.5h, the catholyte was taken out after the electrolysis was completed, separated and purified to obtain 1-ethyl-3-methylimidazolium phosphate ionic liquid with a purity of 83wt%, and its H 1 NMR: 8.706(s, 1H), 7.485(s, 1H), 7.419(s, 1H), 4.211(q, 2H), 3.8...

Embodiment 2

[0026] A preparation method of imidazole dialkyl phosphate ionic liquid, electrolysis is carried out in an electrolytic cell including a cathode chamber and an anode chamber, a layer of perfluorinated cation exchange membrane is also arranged between the cathode chamber and the anode chamber, and graphite is used as the Anode, Pt as the cathode, the acetonitrile solution of N-ethylimidazole with a concentration of 1mol / L is added to the cathode chamber of the electrolytic cell as the catholyte, and the acetonitrile solution of triethyl phosphate with a concentration of 3mol / L is used as the anolyte Put it into the anode chamber of the electrolytic cell, turn on the silicon rectifier power supply, the electrolysis temperature is 75°C, and the current density is 7A / dm 2 Under the conditions of electrolysis for 6 hours, the current efficiency is 30%. After the electrolysis is completed, the catholyte is taken out and put into a rotary evaporator for rotary evaporation to obtain 1-...

Embodiment 3

[0029] A preparation method of imidazole dialkyl phosphate ionic liquid, electrolysis is carried out in an electrolytic cell including a cathode chamber and an anode chamber, a layer of perfluorinated cation exchange membrane is also arranged between the cathode chamber and the anode chamber, and a Ti-based PbO 2 Is the anode, Pt is the cathode, the concentration is 1.5mol / L the acetonitrile solution of N-ethylimidazole is added in the cathode chamber of the electrolyzer as the catholyte, the concentration is the acetonitrile solution of the tributyl phosphate of 1.5mol / L as Add the anolyte into the anode chamber of the electrolytic cell, turn on the silicon rectifier power supply, and the electrolysis temperature is 80°C, and the current density is 1.5A / dm 2 Under the conditions of electrolysis for 9 hours, the current efficiency is 40%. After the electrolysis is completed, the catholyte is taken out and put into a rotary evaporator for rotary evaporation to obtain 1-butyl-3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com