Light extraction film for OLED illumination device and manufacturing method thereof

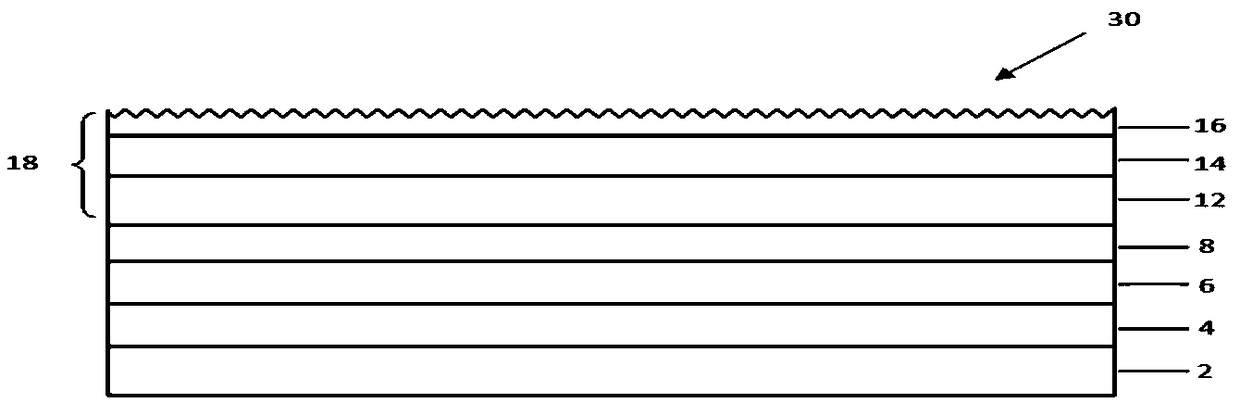

A technology for light extraction films and lighting devices, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of cumbersome preparation process, unfavorable mass production, complex structure of light extraction films, etc., and achieve uniform light. , to avoid the reduction of light extraction efficiency and the effect of reducing glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

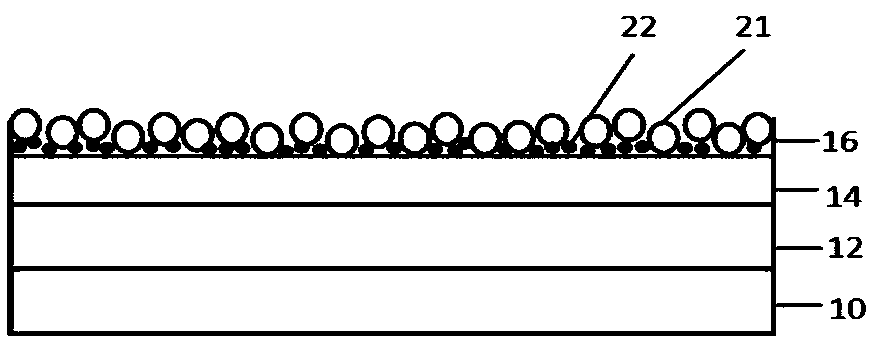

[0038] 2. For the preparation of the high refractive index concave-convex coating 16 coating liquid, select a thermosetting resin or a photocurable prepolymer as the film-forming resin component of the concave-convex layer, select a solvent or an active monomer as a diluent, and select nanoparticles 22 It is dispersed in the film-forming material resin, and the refractive index of the coating after film formation is adjusted by the nanoparticles and the film-forming resin to not be lower than the refractive index of the support body. The added micron-sized particles 21 are used as a coating protrusion regulator and as a light scattering effect, and the coating has a concave-convex surface after curing.

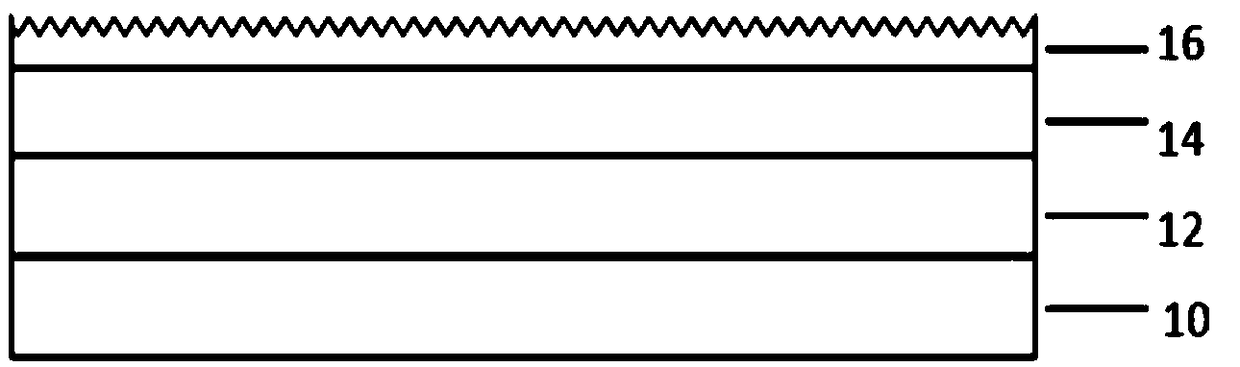

[0039] 3. Low-refractive-index bonding layer coating, coating a low-refractive index bonding layer on one side of the support, coating thickness 3-20 μm, preferably 5-8 μm, thermal curing or UV radiation curing, synchronous compounding during winding protective film10.

[004...

Embodiment 1

[0043] Low refractive index bonding layer coating solution consists of 63 grams of UV-curable acrylic pressure-sensitive adhesive, 10 grams of aluminum oxide nanoparticles, 20 grams of butyl acetate, 2 grams of bridging agent, and 4 grams are added after the dispersion is uniform. Photoinitiator 184, 1 g each of defoamer, leveling agent, and substrate wetting agent, stirred evenly, and the refractive index is 1.5-1.55.

[0044] The high refractive index concave-convex coating coating solution consists of 50 grams of polyester acrylic resin, 20 grams of nano-zinc oxide particles, 8 grams of polyethylene glycol diacrylate, and 6 grams of trimethylolpropane triacrylate. 10 grams of 5 μm polystyrene microspheres, 4 grams of photoinitiator 184 and defoamer, and 1 gram of substrate wetting agent, were prepared as a coating solution with a refractive index of 1.65-1.70.

[0045] The polyester film (PET) with a refractive index of 1.6 is selected, and the adhesive layer is coated with...

Embodiment 2

[0047] 60 grams of polyacrylate pressure-sensitive adhesive is selected as the low-refractive index bonding layer coating solution, 22 grams of toluene is selected as the first diluent, 3 grams of bridging agent and catalyst, and 14 grams of magnesium oxide nanoparticles are uniformly dispersed and added to solidify 3 grams of agent, and 1 gram each of defoamer, leveling agent, and substrate wetting agent, stir evenly, and the refractive index is 1.5-1.55.

[0048] The high refractive index concave-convex coating coating liquid is composed of 52 grams of thermosetting acrylic resin, 20 grams of nano-zirconia particles, 10 grams of benzene solvent and gasoline mixed solvent, uniformly dispersed, and adding 12 polymethyl methacrylate microspheres with a particle size of 3 μm. gram, 4 grams of curing agent, 1 gram of defoaming agent, 1 gram of substrate wetting agent, and configured as a coating solution with a refractive index of 1.65-1.70.

[0049] A polyester film (PET) with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com