Porous nitrogen-doped carbon intercalated coated ferric oxide nano panel material and preparation method thereof

A technology of nano-iron oxide and nitrogen-doped carbon, which is applied in the direction of electrochemical generators, electrical components, battery electrodes, etc., can solve the problem of limited contact area, and achieve the effects of broad application prospects, enhanced close contact, and controllable components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Disperse 0.05g of ferric oxychloride and 0.5mL of aniline into 20mL of acetonitrile, and react at 90°C for 12h to obtain solvothermal product A;

[0028] (2) The solvothermal product A was washed three times with ethanol, and then dried at 80° C. for 12 hours to obtain product B;

[0029] (3) The product B was calcined under a nitrogen atmosphere, that is, the temperature was raised to 700° C. at a heating rate of 5° C. / min, and then kept for 4 hours to form a finished porous carbon intercalation-coated iron oxide nanoplate.

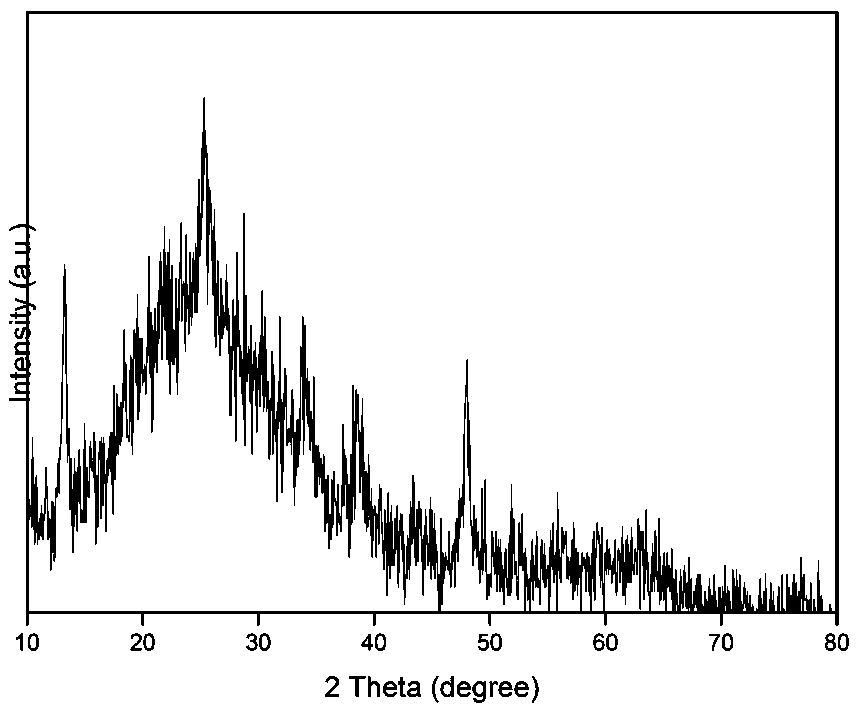

[0030] Depend on figure 1 It can be seen that the disappearance of ferric oxychloride (010) peak (11.05 o ) and a new characteristic peak (12.5 o ), indicating that aniline in the product B is successfully intercalated into the ferric oxychloride interlayer;

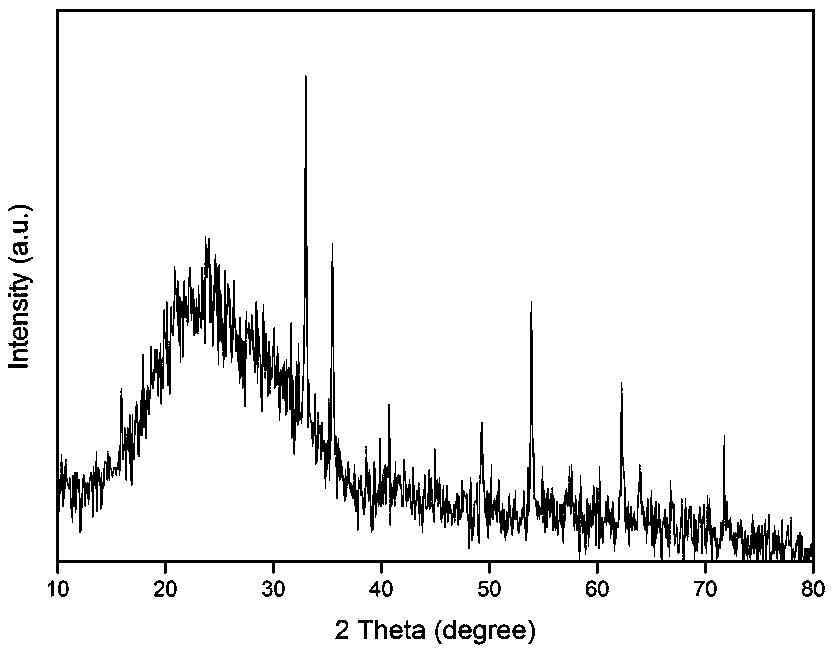

[0031] Depend on figure 2 It can be seen that the calcined product is nitrogen-doped carbon-coated iron oxide, and the crystal form of nitrogen-doped carbon is an amorphous structur...

Embodiment 2

[0035] As described in Example 1, the difference is that 0.5g of diphenylamine is added and reacted in ethanol at 120°C for 20h. During calcination, the product B is heated to 900°C at 2°C / min under a nitrogen atmosphere for 5h and then porous carbon intercalation Coated iron oxide nano plate material. The finished product prepared in this embodiment can completely degrade rhodamine B within 60 minutes.

Embodiment 3

[0037] As described in Example 1, the difference is that 1.0 mL of dimethylaniline is added and reacted in ethanol at 180°C for 10 hours. During calcination, the product B is heated to 850°C at 10°C / min under a nitrogen atmosphere for 4 hours, and then porous carbon is obtained. Intercalation coated iron oxide nano plate material. The finished product prepared in this embodiment can degrade 98% rhodamine B within 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com