Preparation method of high-density garnet type inorganic solid electrolyte material

A solid electrolyte, garnet-type technology, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problem of low density, achieve the effect of improving sintering density, obvious effect, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

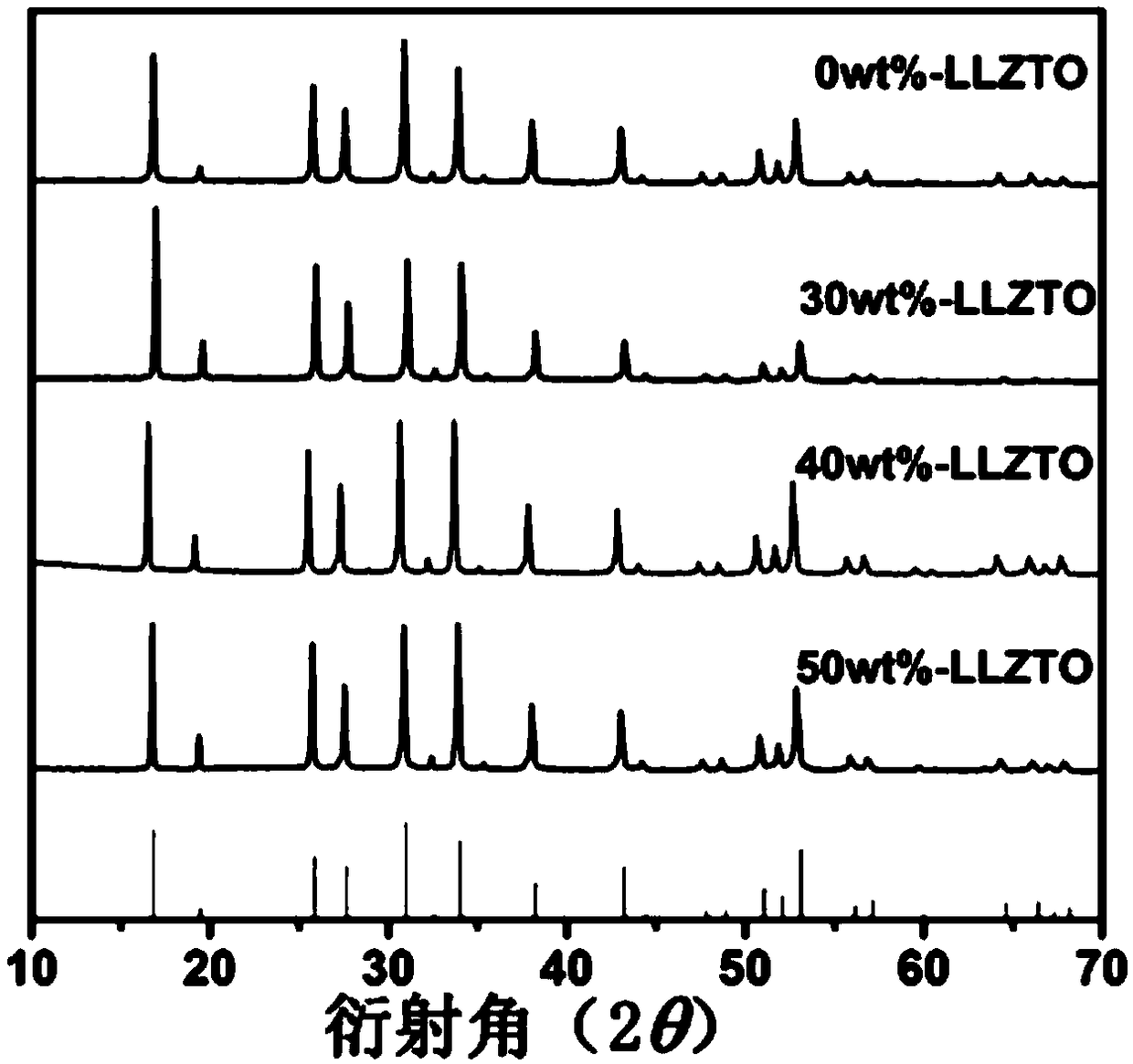

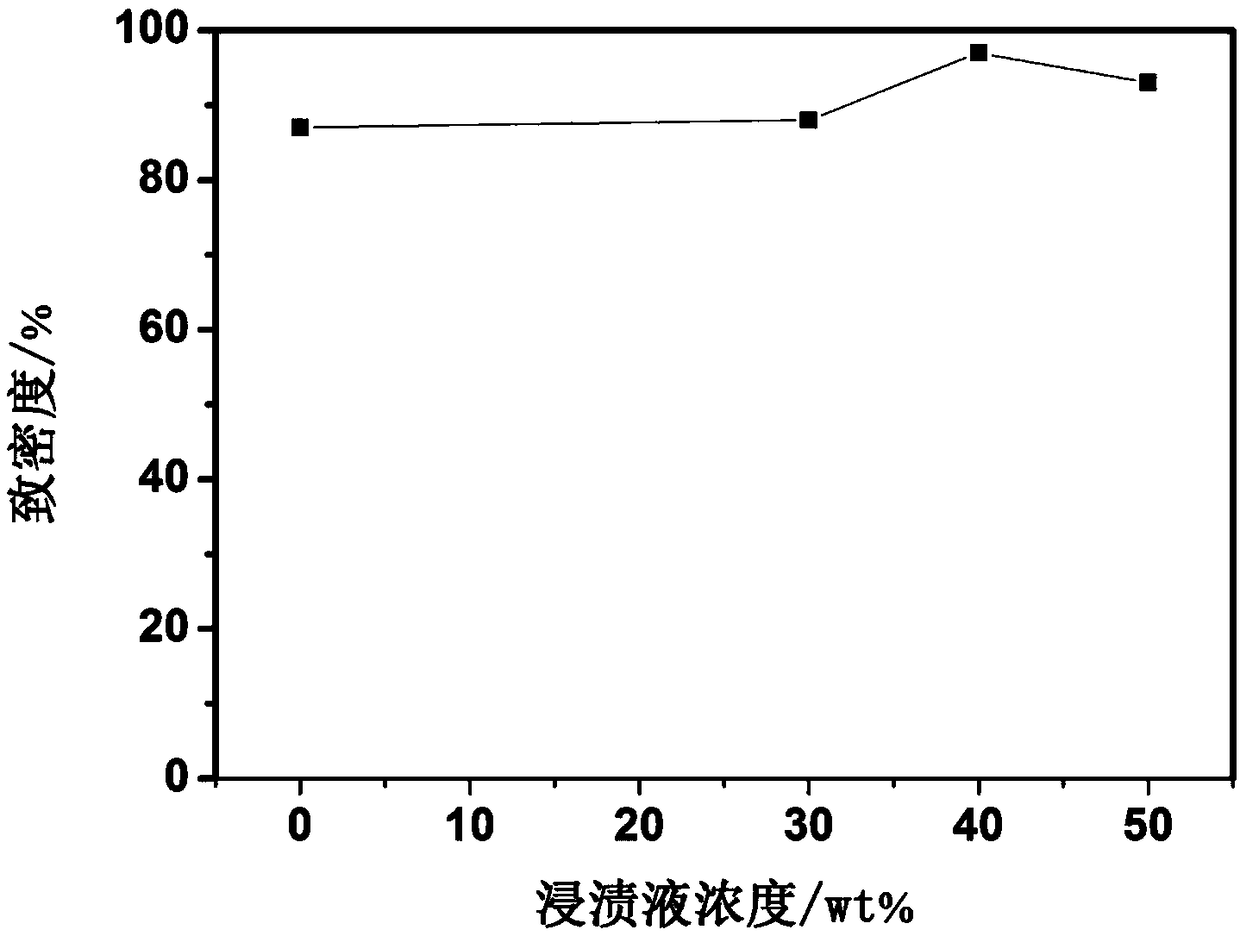

[0032] The preparation method of the high-density garnet type solid electrolyte with the impregnating liquid concentration of 30wt% specifically comprises the following steps:

[0033] (1) Unimpregnated garnet-type solid electrolyte material

[0034] Weigh 2.7797g of lithium carbonate, 4.8871g of lanthanum oxide, 2.1686g of zirconia, and 0.5320g of tantalum pentoxide into an agate ball mill jar, add agate beads (according to the ratio of ball mill beads, large, medium, and small: 1:6:30) ) and absolute ethanol (20ml) for ball milling, after the ball milling, dry in a blast oven at 80 degrees Celsius for 12 hours, put the dried raw materials in an alumina crucible and put them in a high-temperature muffle furnace for sintering, and control the heating rate 10°C / min to raise the temperature to 950°C for 6 hours, then cool down to room temperature with the furnace temperature to obtain the precursor powder, fully grind the precursor powder in a mortar, and then screen the precurs...

Embodiment 2

[0040] The preparation method of the high-density garnet type solid electrolyte with the impregnating liquid concentration of 40wt% specifically comprises the following steps:

[0041] (1) Unimpregnated garnet-type solid electrolyte material

[0042] Weigh 2.7797g of lithium carbonate, 4.8871g of lanthanum oxide, 2.1686g of zirconia, and 0.5320g of tantalum pentoxide into an agate ball mill jar, add agate beads (according to the ratio of ball mill beads, large, medium, and small: 1:6:30) ) and absolute ethanol (20ml) for ball milling, after the ball milling, dry in a blast oven at 80 degrees Celsius for 12 hours, put the dried raw materials in an alumina crucible and put them in a high-temperature muffle furnace for sintering, and control the heating rate 10°C / min to raise the temperature to 950°C for 6 hours, then cool down to room temperature with the furnace temperature to obtain the precursor powder, fully grind the precursor powder in a mortar, and then screen the precurs...

Embodiment 3

[0048] The preparation method of the high-density garnet type solid electrolyte with the impregnating liquid concentration of 50wt% specifically comprises the following steps:

[0049] (1) Unimpregnated garnet-type solid electrolyte material

[0050] Weigh 2.7797g of lithium carbonate, 4.8871g of lanthanum oxide, 2.1686g of zirconia, and 0.5320g of tantalum pentoxide into an agate ball mill jar, add agate beads (according to the ratio of ball mill beads, large, medium, and small: 1:6:30) ) and absolute ethanol (20ml) for ball milling, after the ball milling, dry in a blast oven at 80 degrees Celsius for 12 hours, put the dried raw materials in an alumina crucible and put them in a high-temperature muffle furnace for sintering, and control the heating rate 10°C / min to raise the temperature to 950°C for 6 hours, then cool down to room temperature with the furnace temperature to obtain the precursor powder, fully grind the precursor powder in a mortar, and then screen the precurs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com