Soybean meal dried tofu and preparation method thereof

A technology of dried bean and bean flour, applied in the field of dried bean flour and the preparation thereof, can solve the problems of high content of oil and fat, increased blood lipids of consumers, health damage, etc., and achieves rich nutrition, low oil content, and production process operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

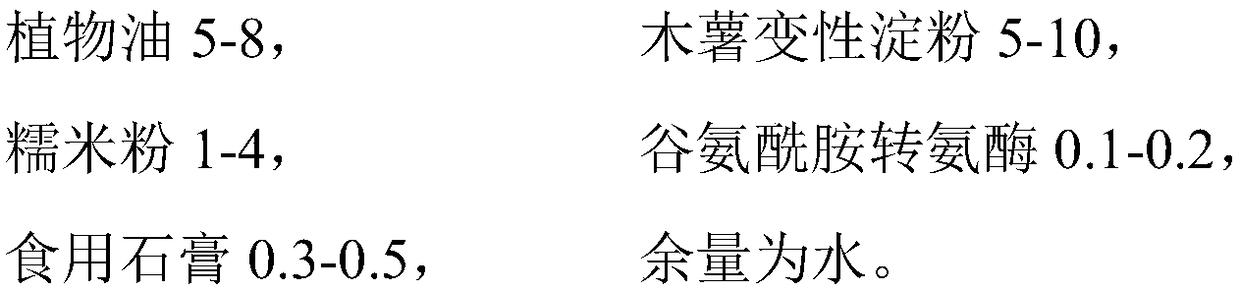

[0043] A kind of bean flour dried bean curd is made from the following raw materials in parts by weight:

[0044]

[0045] The preparation method is as follows:

[0046] (1) Preparation of marinated slurry: add 7 times the weight of water to the soybean powder, add edible gypsum to it after mixing evenly, chop and mix in a chopping machine for 1min, and the rotating speed is 1000r / min, to obtain the marinated slurry for later use;

[0047] (2) Hydration: Mix soybean protein with 3 times the weight of water, first chop and mix at a speed of 1000r / min for 0.5-1min, after the materials are mixed, chop and mix at a speed of 3000r / min for 5min to obtain a hydrated slurry ;

[0048] (3) Emulsification: Add vegetable oil to the obtained hydrated slurry, continue chopping and stirring at a speed of 3000r / min for 3min, and obtain an emulsified slurry;

[0049] (4) Mixing: mix the cassava modified starch, glutinous rice flour and transglutaminase evenly and add them to the above-me...

Embodiment 2

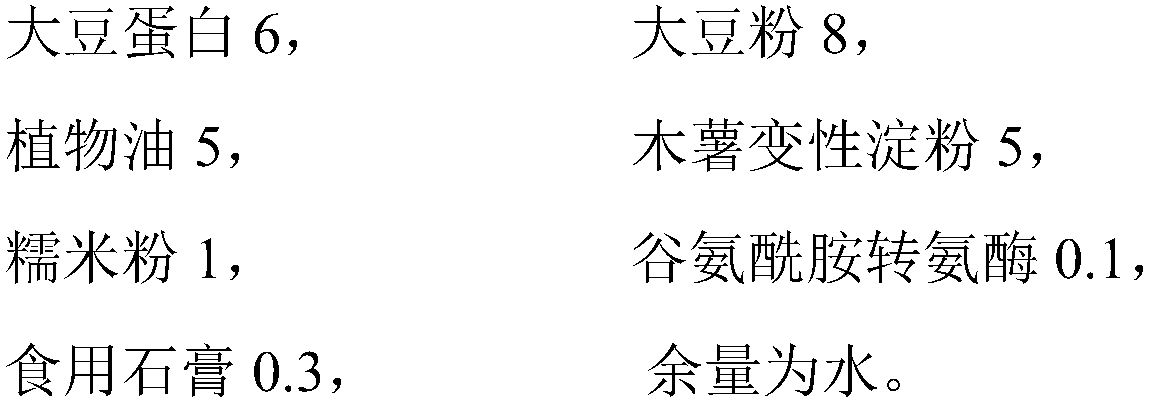

[0055] A kind of bean flour dried bean curd is made from the following raw materials in parts by weight:

[0056]

[0057] The preparation method is as follows:

[0058] (1) Preparation of marinated slurry: add 7 times the weight of water to the soybean powder, add edible gypsum to it after mixing evenly, chop and mix in a chopping machine for 1min, and the rotating speed is 1000r / min, to obtain the marinated slurry for later use;

[0059] (2) Hydration: Mix soybean protein with 3 times the weight of water, first chop and mix at a speed of 1000r / min for 0.5-1min, after the materials are mixed, chop and mix at a speed of 3000r / min for 5min to obtain a hydrated slurry ;

[0060] (3) Emulsification: Add vegetable oil to the obtained hydrated slurry, continue chopping and stirring at a speed of 3000r / min for 3min, and obtain an emulsified slurry;

[0061] (4) Mixing: mix the cassava modified starch, glutinous rice flour and transglutaminase evenly and add them to the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com