Preparation method of whole Chinese yam powder and application of whole Chinese yam powder

A technology of yam whole powder and yam, which is applied in the field of food processing, can solve the problems of difficulty in realizing full utilization of yam raw materials, low overall utilization rate of yam raw materials, waste, etc., and achieve the effect of retaining nutritional value, realizing full utilization, and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

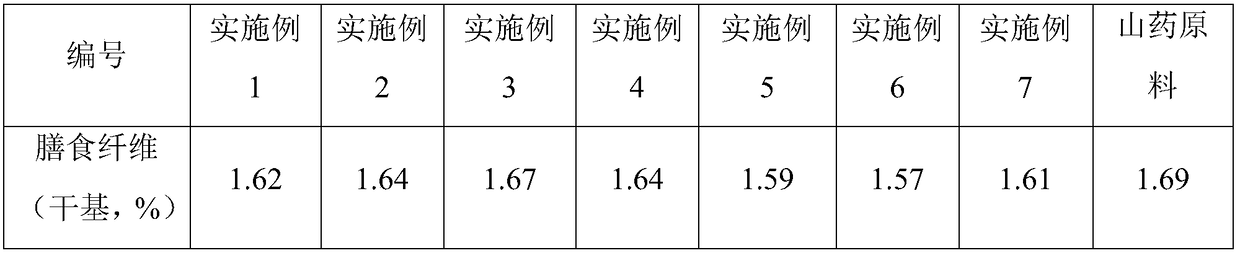

Embodiment 1

[0072] The implementation steps of this embodiment are as follows:

[0073] A. Raw material pretreatment

[0074] Taking no slicing as a control, fresh yams are taken for cleaning to remove surface mud and sand, and then the cleaned yams are cut into 1.5cm yam slices to obtain yam slices;

[0075] B. Color protection

[0076] The sliced yam in step A is placed in the color protection solution, the mass ratio of the color protection solution to the yam tablets is 3:1, and the color protection solution contains citric acid with a mass concentration of 0.3%, 0.2% D-iso Sodium ascorbate and 0.3% NaCl are soaked at room temperature for 35 minutes, and then the color-protecting solution on the surface is washed off to obtain fresh yam after color protection;

[0077] C. Refining

[0078] Add 2% D-sodium erythorbate based on the weight of fresh yam to the fresh yam obtained in step C after color protection, and then grind it into a slurry using a refining equipment until the slu...

Embodiment 2

[0087] The implementation steps of this embodiment are as follows:

[0088] A. Raw material pretreatment

[0089] Get fresh yam to clean, remove the surface mud and sand, then cut the cleaned yam into 2.0cm yam slices to obtain yam slices;

[0090] B. Color protection

[0091] Taking no place in the color-protecting solution as a control, place the sliced yam in step A in the color-protecting solution, the mass ratio of the color-protecting solution to the yam tablets is 2.5:1, and the color-protecting solution contains 0.3% of Soak citric acid, 0.2% sodium D-isoascorbate and 0.3% NaCl at room temperature for 35 minutes, then rinse off the color-protecting solution on the surface to obtain fresh yam after color protection;

[0092] C. Refining

[0093] Add 2% D-sodium erythorbate based on the weight of fresh yam to the fresh yam obtained in step C after color protection, and then grind it into a slurry using a refining equipment until the slurry can pass through a 65-mesh...

Embodiment 3

[0102] The implementation steps of this embodiment are as follows:

[0103] A. Raw material pretreatment

[0104] Get fresh yam to clean, remove the surface mud and sand, then cut the cleaned yam into 2.0cm yam slices to obtain yam slices;

[0105] B. Color protection

[0106] The sliced yam in step A is placed in the color protection solution, the mass ratio of the color protection solution to the yam tablets is 3:1, and the color protection solution contains citric acid with a mass concentration of 0.3%, 0.2% D-iso Sodium ascorbate and 0.3% NaCl are soaked at room temperature for 35 minutes, and then the color-protecting solution on the surface is washed off to obtain fresh yam after color protection;

[0107] C. Refining

[0108] Taking no addition of D-sodium erythorbate as a control, add 2% D-sodium erythorbate in terms of fresh yam weight to the fresh yam obtained in step C after color protection, and then use a refining equipment to grind it into a slurry until Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com