Preparation method of sodium alginate-cyclodextrin based material for treating metal processing wastewater

A sodium alginate and metal processing technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of slow adsorption speed and low material strength, and achieve improved adsorption efficiency and water solubility Good, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

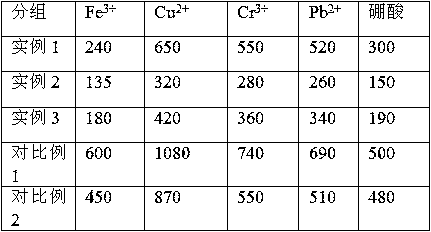

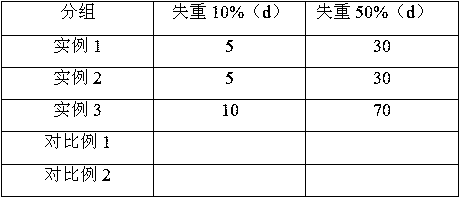

Examples

Embodiment 1

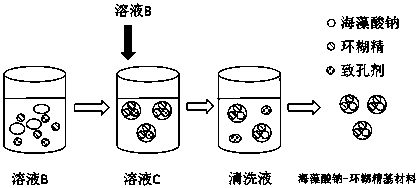

[0028] A method for preparing a sodium alginate-cyclodextrin-based material for treating metal processing wastewater, comprising the following steps:

[0029] 1) Prepare 10g of sodium alginate, 2g of β-cyclodextrin, and 1g of nano-silica, mix well, add 400ml of deionized water, stir at 30°C for 12h, and make a uniform solution A;

[0030] 2) Add 15ml PEG-400 to solution A, stir at 30°C for 24 hours, and make uniform solution B;

[0031] 3) Prepare 400ml cross-linking agent aqueous solution C, the mass concentration of cross-linking agent is 4% CaCl 2 +2% glutaraldehyde;

[0032] 4) Slowly add solution B to solution C dropwise at a rate of 20 drops / min, and stir and react for 24 hours at 50°C under nitrogen protection to obtain the crude material;

[0033] 5) The crude product obtained in step 4) was washed with ethanol for 3 times, then washed with deionized water for 3 times, and then dried at 60°C to obtain a sodium alginate-cyclodextrin-based material. The channel formati...

Embodiment 2

[0035] A method for preparing a sodium alginate-cyclodextrin-based material for treating metal processing wastewater, comprising the following steps:

[0036] 1) Prepare 10g sodium alginate, 3g cyclodextrin-modified nano-titanium dioxide (the preparation method of cyclodextrin-modified nano-titanium dioxide is: cyclodextrin 1g + nano-titanium dioxide 1g, under nitrogen protection, grind and mix in a mortar for 1h), 1g of nano-silica, after uniform mixing, add 400ml of deionized water, stir at 30°C for 12h, and make a uniform solution A;

[0037] 2) Add 40ml of 10% PVA-124 aqueous solution (mass concentration) to solution A, stir at 30°C for 24 hours, and make a uniform solution B;

[0038] 3) Prepare 400ml cross-linking agent aqueous solution C, the cross-linking agent content is 4% CaCl2+2% glutaraldehyde;

[0039] 4) Slowly add solution B dropwise to solution C at a rate of 25 drops / min, stir and react for 24 hours at 50°C under nitrogen protection to obtain the crude mater...

Embodiment 3

[0042] A method for preparing a sodium alginate-cyclodextrin-based material for treating metal processing wastewater, comprising the following steps:

[0043] 1) Prepare 10g of sodium alginate, 3g of cyclodextrin-modified nano-titanium dioxide (cyclodextrin 1g + nano-titanium dioxide 1g, under nitrogen protection, grind and mix in a mortar for 1h), 1g of nano-silicon dioxide, mix evenly, add 400ml Stir in deionized water for 12 hours at 30°C to prepare a homogeneous solution A;

[0044] 2) Add 40ml PEG-400 to solution A, stir at 30°C for 24 hours, and make uniform solution B;

[0045] 3) Prepare 400ml crosslinking agent aqueous solution C, the mass concentration of crosslinking agent is 4% calcium acetate + 2% epichlorohydrin;

[0046]4) Slowly add solution B to solution C dropwise at a rate of 20 drops / min, and stir and react for 24 hours at 50°C under nitrogen protection to obtain the crude material;

[0047] 5) The crude material obtained in step 4) was washed with ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com