Regeneration method for activated carbon or carbon-based catalyst

A carbon-based catalyst, activated carbon technology, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of selective biodegradation, high investment and operating costs, secondary environmental pollution, etc. problems, to achieve the effect of short regeneration time, low investment and operation cost, and protection of the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

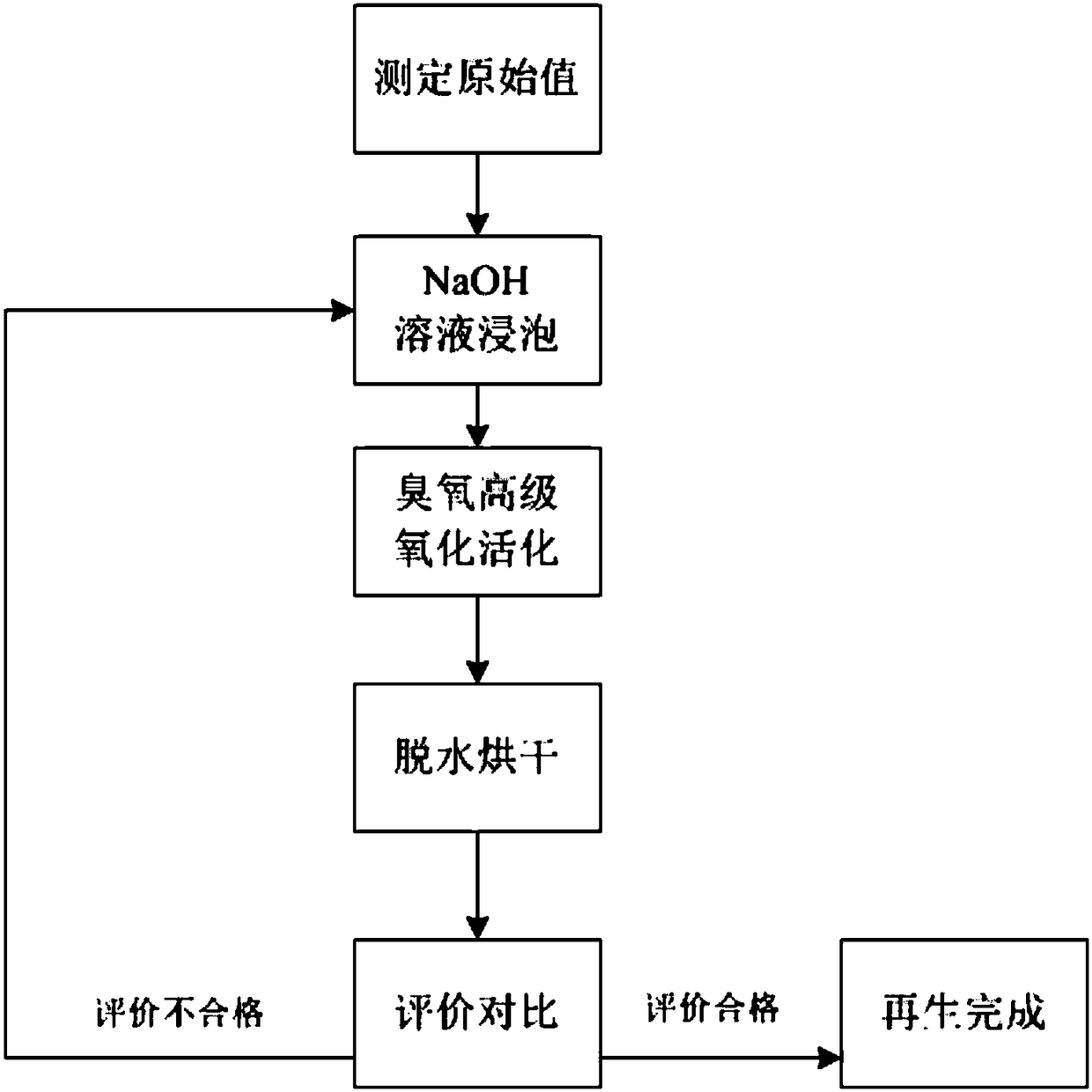

Method used

Image

Examples

Embodiment 1

[0040] Take 50g of saturated coconut shell activated carbon, and measure its methylene blue value to be 130; soak it in 100mL water, add NaOH to adjust the pH to be greater than 12, aerate with an appropriate amount of ozone, and adjust the ventilation to make coconut shell activated carbon in the form of a fluidized bed Float up and down in the water, stop the aeration after keeping the reaction for 2 hours, take out the coconut shell activated carbon and wash it clean, measure its methylene blue value to 226, calculate the activation rate to be 74%, and achieve the activation effect.

Embodiment 2

[0042] Take 50g of the carbon-based catalyst after repeated use, measure its initial COD removal capacity of 55.39% for the test water with COD=594mg / L, then soak it in 100mL water, add NaOH to adjust the pH to greater than 12, and aerate with an appropriate amount of ozone to adjust the ventilation Make the carbon-based catalyst float up and down in the water in the form of a fluidized bed, stop the aeration after the reaction residence time is 1h, take out the carbon-based catalyst and rinse it clean, and the activated carbon-based catalyst is used to catalyze the ozone oxidation of COD=594mg / L Test water, the COD removal rates measured by multiple parallel tests are: 85.86%, 84.85%, 90.57%, 88.89%, 90.07%. Average value = 88.5mg / L, the COD removal rate of the tested water sample was increased from 55.39% to 88.5% under the action of the catalyst, which proves that the catalyst activity has been significantly improved.

[0043] Regeneration and activation mechanism of activa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com