N-butanol gas sensitive material and preparation method thereof

A gas-sensitive material and technology for sensitive materials, applied in the field of n-butanol gas-sensitive materials and their preparation, to achieve the effects of high sensitivity, increased thickness, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The second aspect of the present invention provides a kind of preparation method of n-butanol gas sensitive material, comprises the steps:

[0032] 1). Weigh zinc acetate dihydrate, indium nitrate monohydrate and polyvinylpyrrolidone, add them into deionized water, stir until dissolved, and make a solution;

[0033] 2). Drying the solution prepared in step 1) of the preparation to obtain a light yellow transparent gel;

[0034] 3). Put the above-mentioned gel into a calciner for firing to obtain a finished product.

[0035] In the step 1), the mass ratio of zinc acetate dihydrate, indium nitrate monohydrate and polyvinylpyrrolidone is 3:0.15-1:2-6; the mass ratio of deionized water to polyvinylpyrrolidone is 40-60 :1. The mass ratio of zinc acetate dihydrate and indium nitrate monohydrate cannot be lower than 3:1. If it is lower than 3:1, white powder will precipitate during the drying process, and transparent gel blocks cannot be obtained. When zinc acetate dihydrate...

Embodiment 1

[0044] 1): Weigh zinc acetate dihydrate, indium nitrate monohydrate and polyvinylpyrrolidone (K88-96) according to the mass ratio of 3:1:3, add them to deionized water, deionized water and polyvinylpyrrolidone (K88-96) The mass ratio is 40:1, stir until completely dissolved, and form a solution.

[0045] 2): Dry the prepared mixed solution at a drying temperature of 70° C. to completely evaporate the water to obtain a mixture of zinc acetate, indium nitrate and polyvinylpyrrolidone (K88-96).

[0046] 3): Put the mixture of zinc acetate, indium nitrate and polyvinylpyrrolidone (K88-96) into the calciner, heat the calciner to 600°C, keep it warm for 2 hours, and finally take out the In from the calciner 2 o 3 Doped ZnO finished product.

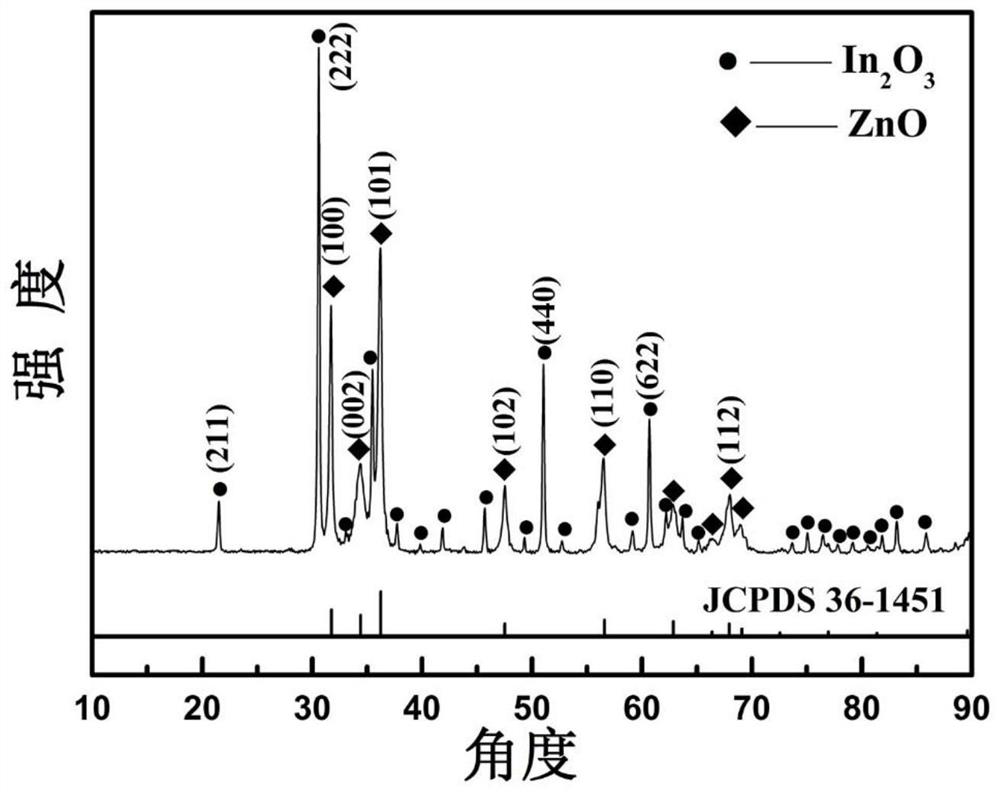

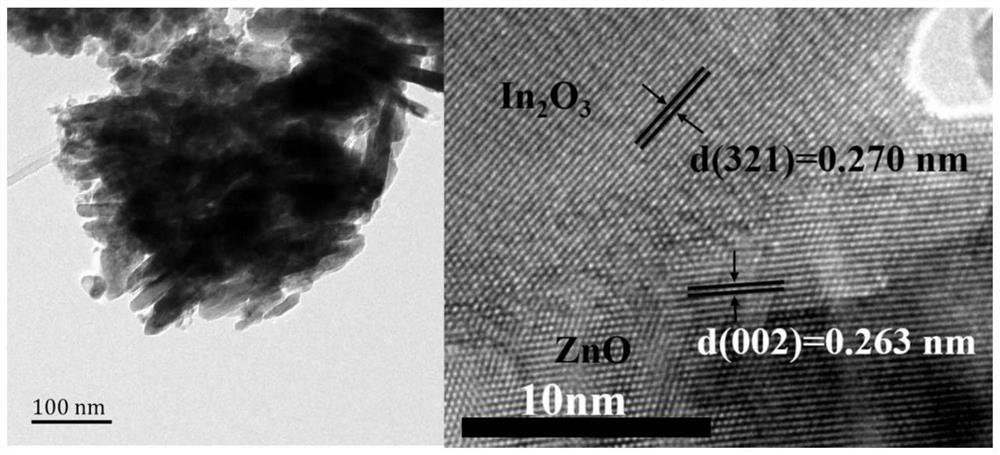

[0047] The samples were tested to obtain figure 1 , figure 2 and image 3 . Depend on figure 1 It can be seen that the sample XRD pattern prepared by using the method of the present invention contains In 2 o 3 and ZnO two phases, indi...

Embodiment 2

[0050] 1): Weigh zinc acetate dihydrate, indium nitrate monohydrate and polyvinylpyrrolidone (K88-96) according to the mass ratio of 3:0.6:2, add them to deionized water, deionized water and polyvinylpyrrolidone (K88-96) The mass ratio is 40:1, stir until completely dissolved, and form a solution.

[0051] 2): Dry the prepared mixed solution at a drying temperature of 40° C. to completely evaporate the water to obtain a mixture of zinc acetate, indium nitrate and polyvinylpyrrolidone (K88-96).

[0052] 3): Put the mixture of zinc acetate, indium nitrate and polyvinylpyrrolidone (K88-96) into the calciner. 2 o 3 Doped ZnO finished product.

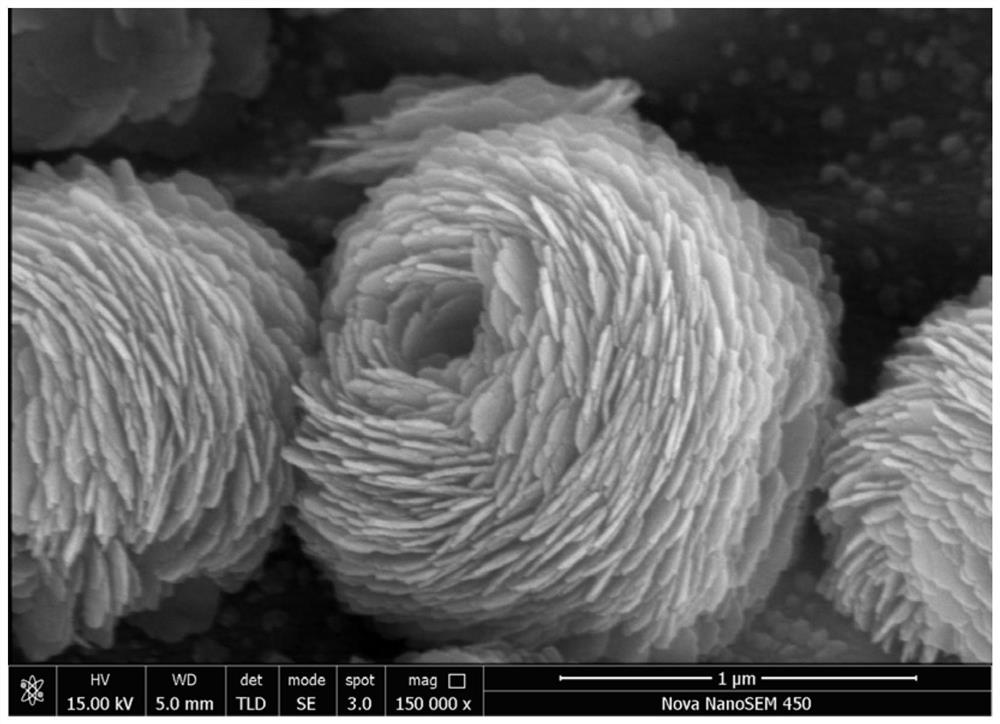

[0053] Product characterization as Figure 4 shown by Figure 4 It can be seen that the microscopic appearance of the product is a micron three-dimensional structure with a diameter of about 1-2.5 μm, and each micron three-dimensional structure is composed of a nanosheet structure. Adopt Zhengzhou Weisheng WS-30 gas sensitivity test sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com