Preparation method and application of straw fiber for asphalt pavement

A technology of straw fiber and asphalt pavement, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of harsh mixing conditions, unstable storage, and high construction costs, and achieve performance improvement, Effects of improving performance and increasing oil absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

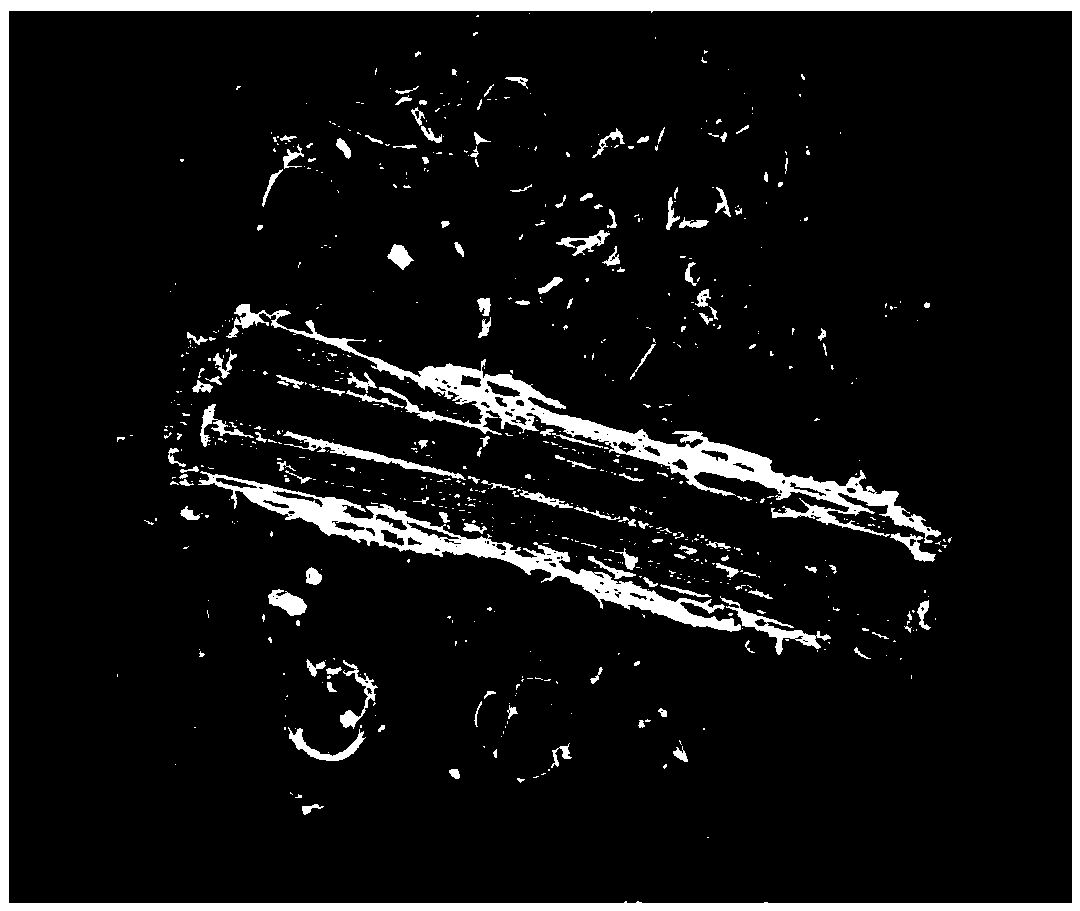

[0023] Specific implementation mode one: the preparation method of straw fiber for green pavement of this embodiment is implemented according to the following steps:

[0024] 1. Separating the husks of corn stalks, washing the separated husks with water, drying to constant weight, and obtaining dried husks;

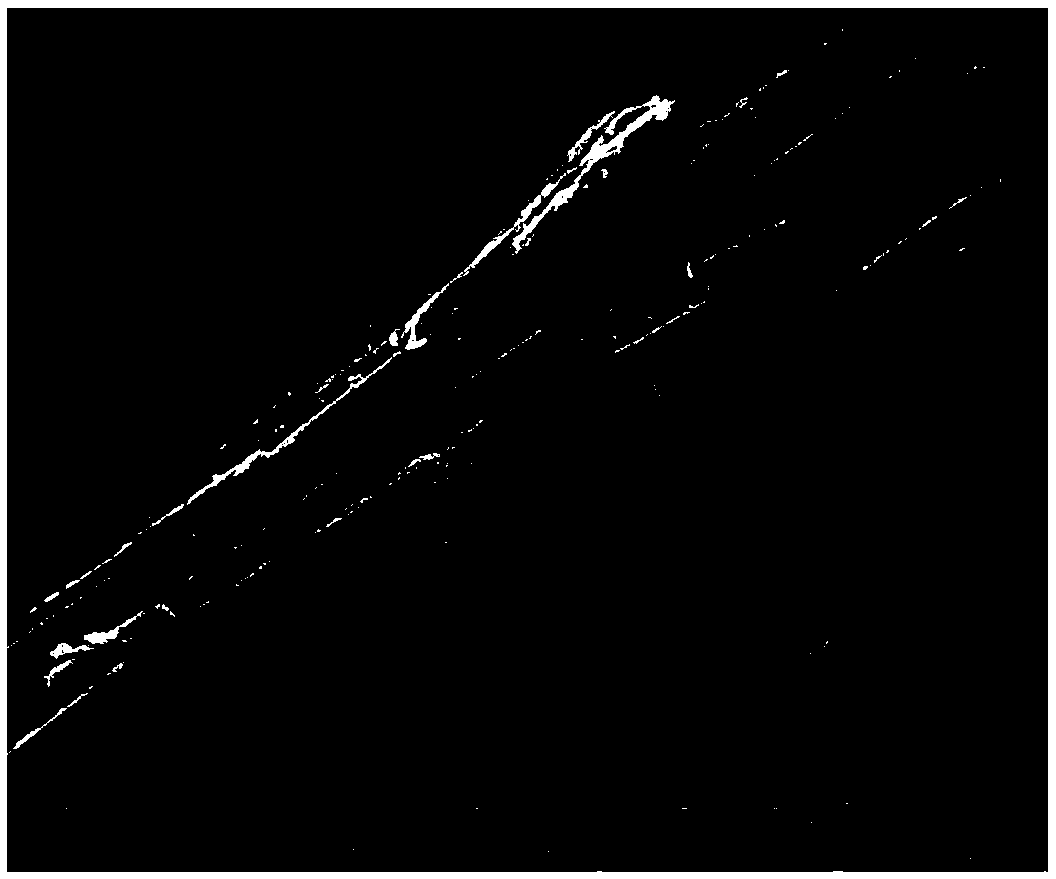

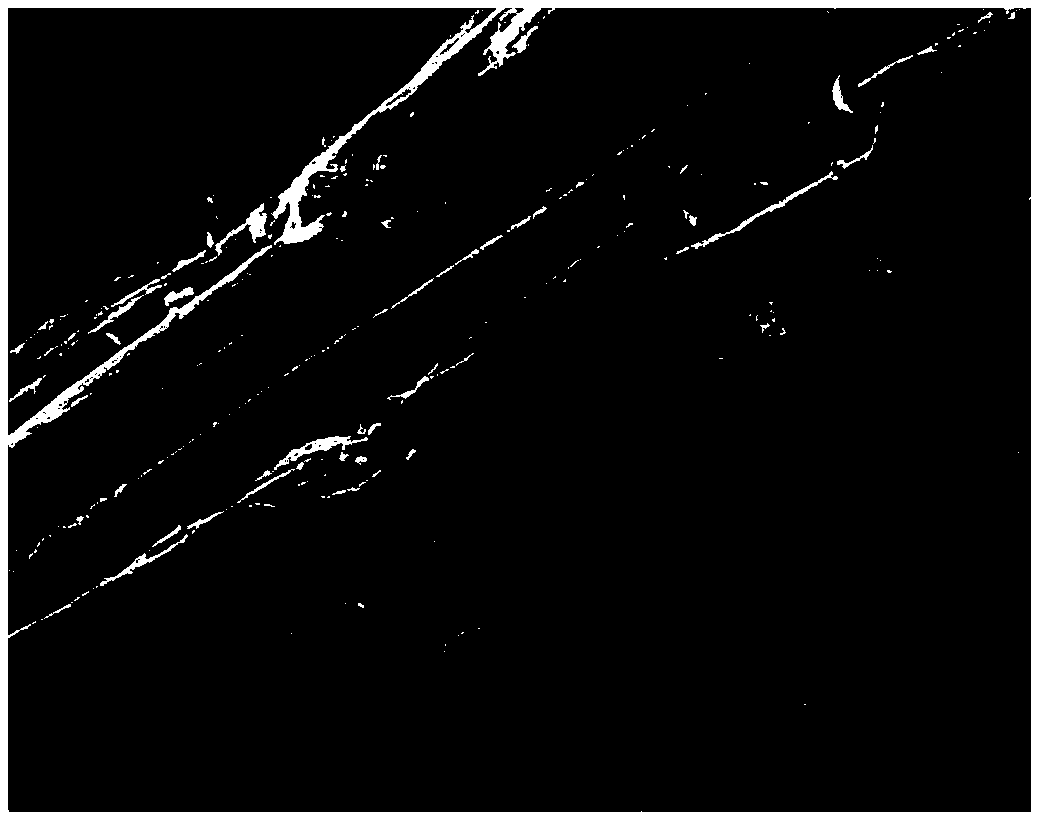

[0025] 2. Cut the dried stalks into strips, crush them with a hammer mill to obtain corn stalk fibers, and then put the corn stalk fibers into a grinder for grinding to obtain ground corn stalk fibers;

[0026] 3. Immerse the ground corn stalk fibers in a sodium hydroxide solution with a mass concentration of 0.25% to 3%, and stir and react at a constant temperature at a temperature of 50 to 90°C for 15 to 60 minutes. After the reaction is completed, use deionized water to carry out Rinse and dry to constant weight to obtain straw fiber material for asphalt pavement.

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, a husk and stalk separator is used to separate the husks and stalks of corn stalks.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that step 2 cuts the dried straw bark into strips with a size of (0.5-1.5 cm)×(2-4 cm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com