Slow-release fertilizer wrapped in microalgae or algae residue and preparation method thereof

A technology of microalgae algae and slow-release fertilizers, applied in layered/coated fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve problems such as refractory degradation and high cost, and achieve improved soil quality, improved economy, and improved mechanical resistance. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

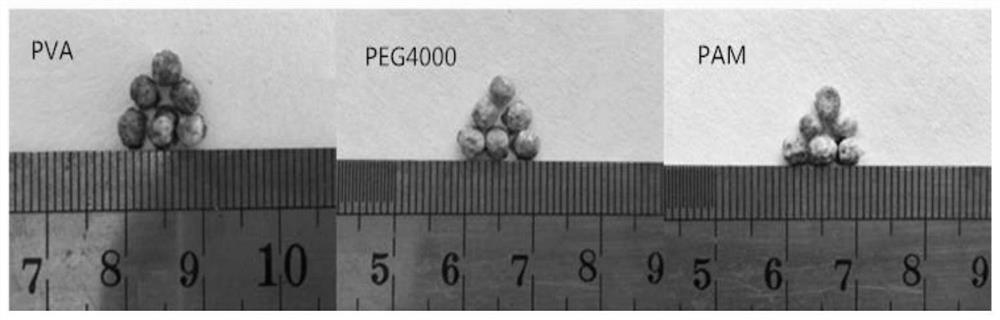

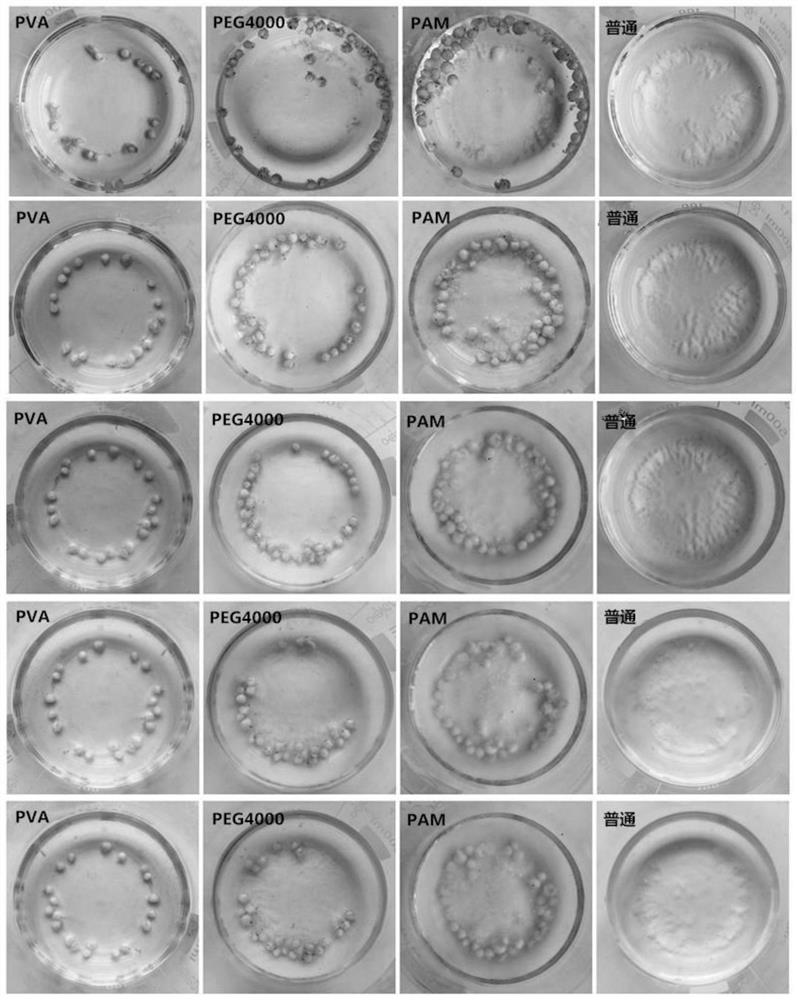

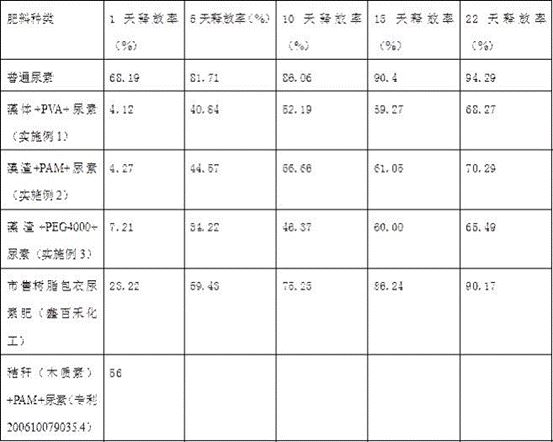

Embodiment 1

[0025] The collected microalgae (the source is Taihu Lake blooms, mainly composed of Microcystis Microcystis aeruginosa ) Naturally air-dried to a water content of 5-10%, ground and pulverized into powder, and passed through a 60-mesh sieve. Prepare a polyvinyl alcohol aqueous solution with a mass concentration of 5%. Add 10 kg of urea granules into the disc granulator, start to rotate the disc, and spray the polyvinyl alcohol aqueous solution evenly on the surface of the granular fertilizer in the form of mist through the high-pressure nozzle. At the same time, the algae body powder is sprinkled into the disc, and the binder is continuously sprayed to wrap the powder on the outer layer of urea until 0.8 kg of the algae body powder is wrapped on the particles. Then dry the slow-release fertilizer after wrapping with hot air blower, until water content is lower than 5%, record algae wrap and account for 7.4% of the gross weight of described slow-release fertilizer, wrap slo...

Embodiment 2

[0029] Microalgae algae (sourced from waste water cultured Chlorella, Chlorella vulgaris ) After oil extraction, the algae residue is dried at 50°C until the water content is less than 5%, pulverized into powder in a ball mill, and passed through a 100-mesh sieve. A polyacrylamide solution with a mass fraction of 0.1% was configured as a binder. Start the fluidized bed, and add 10 kilograms of urea granules to it to make the urea fluidize stably in the bed. Spray the binder into the nozzle on the side wall of the fluidized bed at high pressure, and at the same time add the algae residue powder from the bottom of the fluidized bed to a final mass of 0.8 kg. Under the action of the binder, the algae residue evenly adheres to the outer layer of the particles At the same time, the hot air stream dries the wrapped slow-release fertilizer. When the water content is lower than 5%, it is considered that the wrapping is completed. It is measured that the algae residue coating account...

Embodiment 3

[0032] The microalgae (the source is artificial cultured spirulina, Spirulina maxima) The algae residue after protein extraction is dried at 50°C until the water content is less than 5%, pulverized into powder in a Raymond mill, and passed through a 150-mesh sieve. The PEG4000 aqueous solution with a mass fraction of 3% was configured as a binder. Add 10 kg of urea granules into the disc granulator, start to rotate the disc, and spray the binder evenly on the surface of the granular fertilizer in the form of mist through the high-pressure nozzle. At the same time, the algae residue powder is sprinkled into the disk, and the binder is continuously sprayed to wrap the powder on the outer layer of urea until 0.8 kg of the algae residue powder is wrapped on the particles. Then dry the slow-release fertilizer after wrapping with hot air blower, until water content is lower than 5%, record that algae dregs wrapping layer accounts for 7.7% of the gross weight of described slow-rele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com