High-strength antistatic polyethylene terephthalate composite material and preparation method thereof

A technology of ethylene glycol phthalate and composite materials, applied in the field of high-strength antistatic polyethylene terephthalate composite materials and its preparation, can solve the problem of static electricity that is difficult to dissipate, easy to charge static electricity, and PET water absorption Poor performance and other problems, to achieve the effect of simple process, excellent antistatic property and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of the above-mentioned high-strength antistatic polyethylene terephthalate composite material, the steps are as follows:

[0037] Step 1. According to the composition and parts by weight, the dried polyethylene terephthalate and the coupling agent are mixed in a high mixer to obtain the first mixture;

[0038] Step 2. Mix the nucleating agent, sodium dodecylbenzenesulfonate, ethylene glycol ethyl ether, antioxidant, compatibilizer, anti-fiber exposure agent, heat stabilizer and the first mixture according to the composition and parts by weight to obtain the second mixture;

[0039] Step 3. Melting, extruding and granulating the obtained second mixture with polyaniline fibers and carbon fibers to obtain a high-strength antistatic polyethylene terephthalate composite material. The extrusion temperature is preferably 220-260°C.

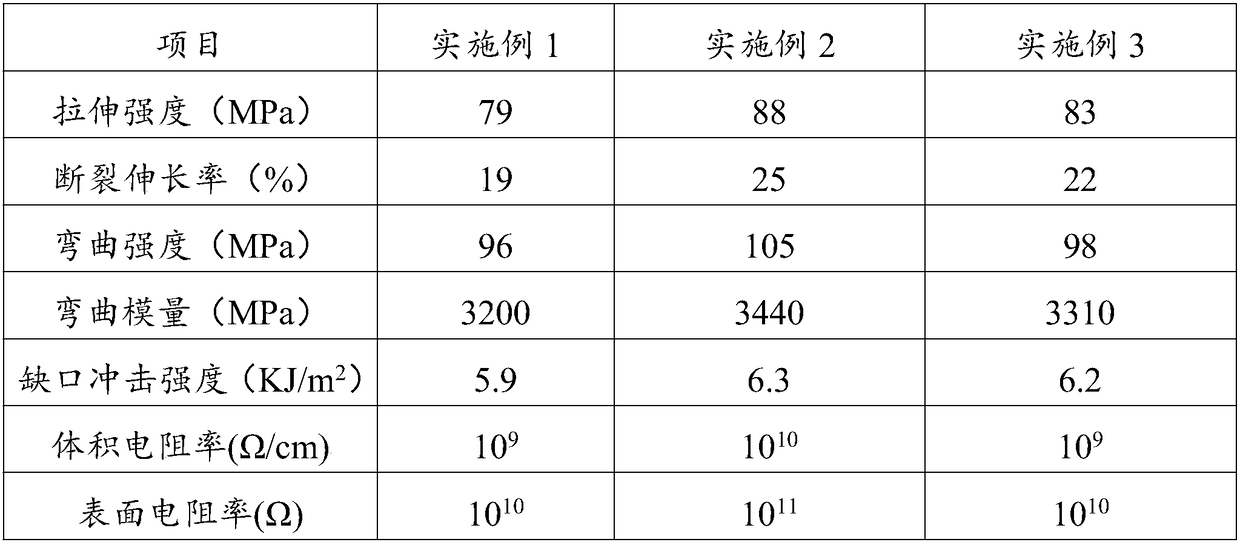

Embodiment 1

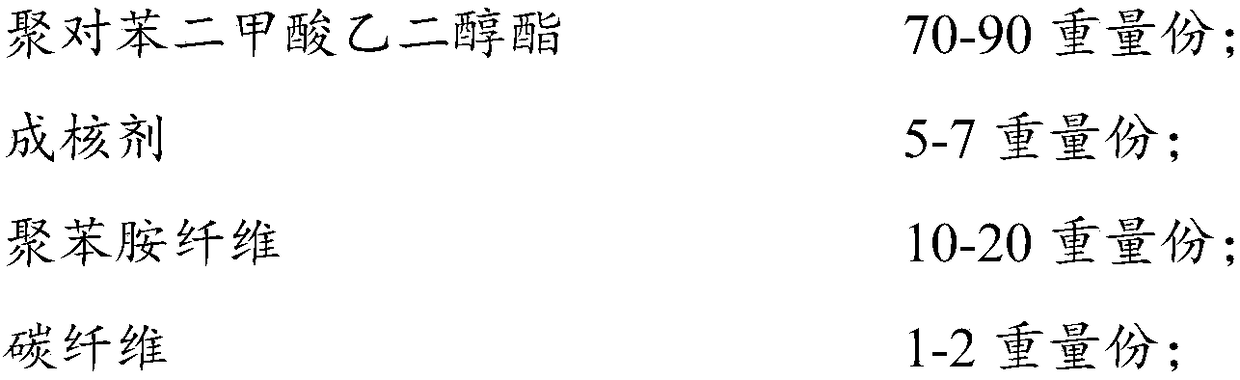

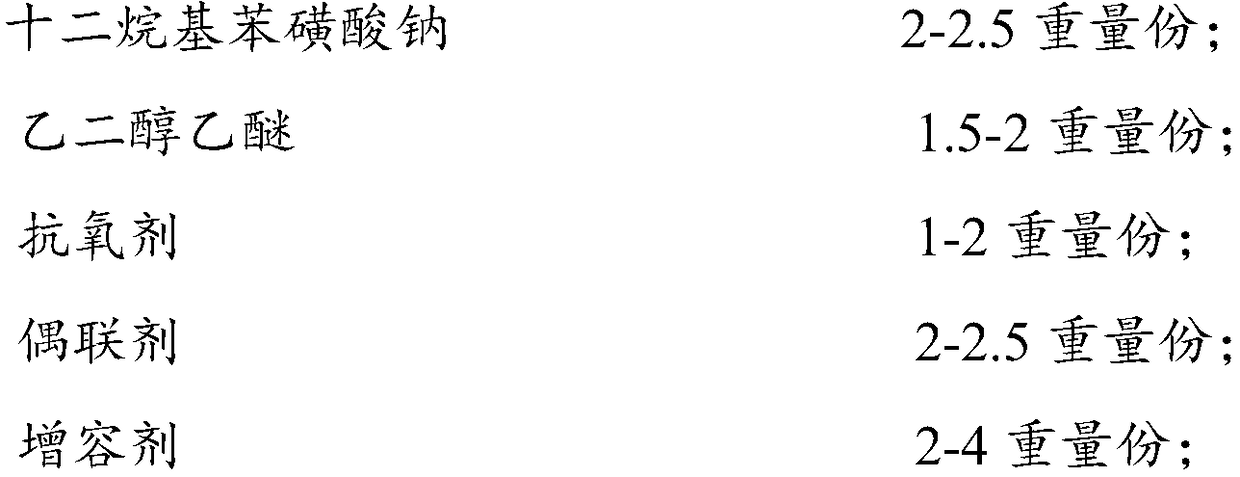

[0042] High strength antistatic polyethylene terephthalate, consists of 70 parts by weight polyethylene terephthalate, 5 parts by weight nucleating agent nano-calcium carbonate, 10 parts by weight polyaniline fiber (8 μm), 1 weight part Parts of carbon fiber, 2 parts by weight of sodium dodecylbenzenesulfonate, 1.5 parts by weight of ethylene glycol ether, 1 part by weight of antioxidant, 2 parts by weight of coupling agent KH550, 2 parts by weight of compatibilizer maleic anhydride grafted linear It consists of low-density polyethylene, 0.5 parts by weight of anti-fiber exposure agent TAF and 0.5 parts by weight of heat stabilizer triphenyl phosphite.

[0043] Preparation of the above-mentioned high-strength antistatic polyethylene terephthalate composite material:

[0044] Step 1. According to the composition and parts by weight, the dried polyethylene terephthalate and the coupling agent are mixed in a high mixer to obtain the first mixture;

[0045] Step 2. Mix the nuclea...

Embodiment 2

[0048] High strength antistatic polyethylene terephthalate, consists of 90 parts by weight polyethylene terephthalate, 7 parts by weight of nucleating agent nano-calcium carbonate, 20 parts by weight polyaniline fiber (10 μm), 2 parts by weight Parts of carbon fiber, 2.5 parts by weight of sodium dodecylbenzenesulfonate, 2 parts by weight of ethylene glycol ether, 2 parts by weight of antioxidant, 2.5 parts by weight of coupling agent KH550, 4 parts by weight of compatibilizer maleic anhydride grafted linear It consists of low-density polyethylene, 1 part by weight of anti-fiber exposure agent TAF and 1 part by weight of heat stabilizer triphenyl phosphite.

[0049] Preparation of the above-mentioned high-strength antistatic polyethylene terephthalate composite material:

[0050] Step 1. According to the composition and parts by weight, the dried polyethylene terephthalate and the coupling agent are mixed in a high mixer to obtain the first mixture;

[0051]Step 2. Mix the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com