Deaminated low-fishy-smell krill oil and preparation method thereof

A technology of krill oil and fishy krill, which is applied in the direction of fat oil/fat refining, fat oil/fat production, edible oil/fat composition, etc., can solve the problems of not being able to prevent trimethylamine and trimethylamine oxide from entering the human body, and harming the human body. Achieve the effects of improving food safety, reducing fishy smell and improving sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

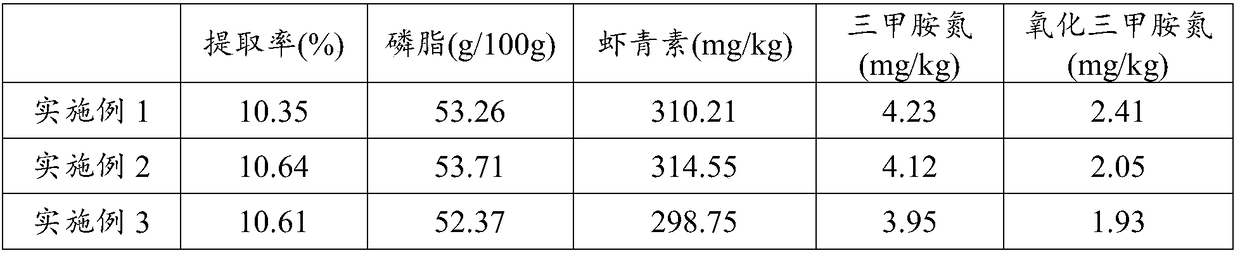

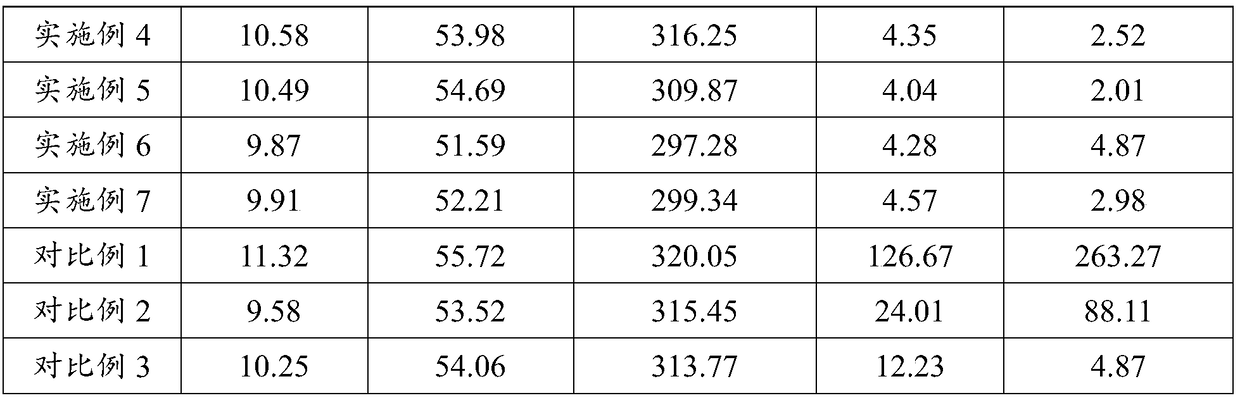

Examples

preparation example Construction

[0028] The preparation method of the deaminated low fishy krill oil provided in the examples of this specification includes:

[0029] Extraction: use Antarctic krill powder as raw material, extract with 90%~100% ethanol as solvent, the ratio of solid to liquid is 1:3-1:6, the extraction time is 30-60min, and the extraction is 3 times, or continuous countercurrent extraction, The ratio of solid to liquid is 1:3-1:6, and the time is 30-60min to obtain the extract;

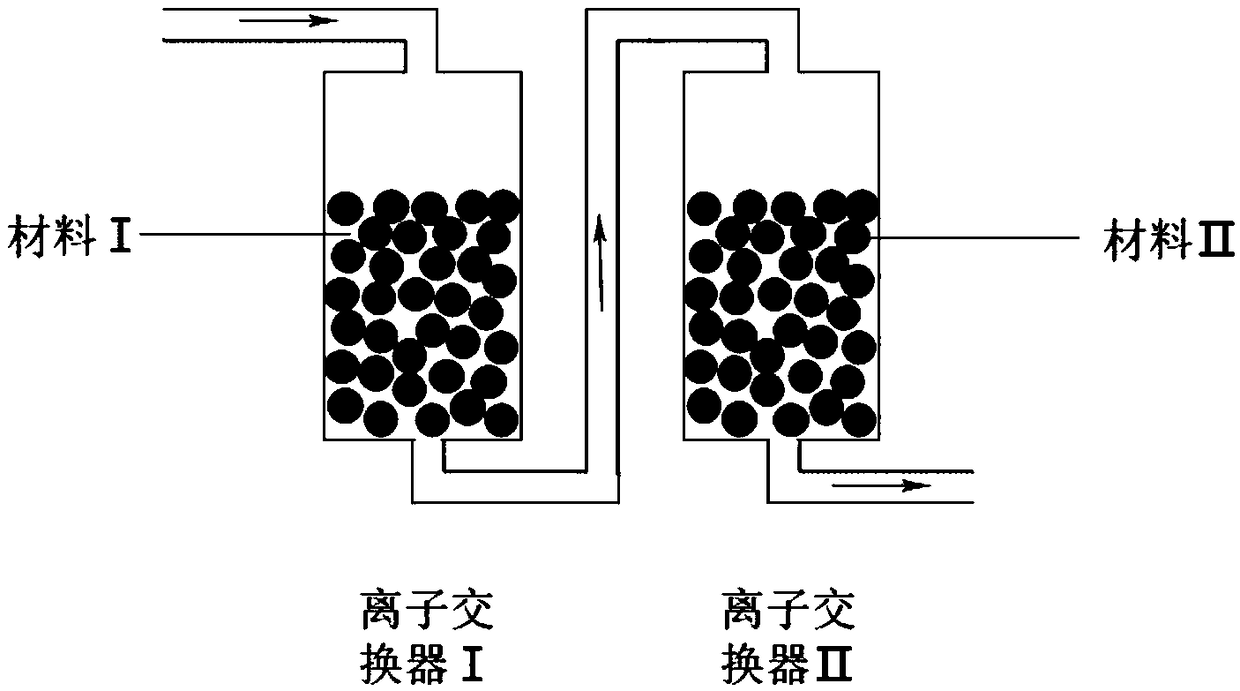

[0030] Adsorption: The extract is deaminated and deodorized by using an adsorption medium. The method is to obtain the effluent through an ion exchange column or filter it after putting it into a reactor to obtain a filtrate;

[0031] Concentration: Concentrate the effluent or filtrate, and the concentration of the concentrated solution after concentration is 10%-20%;

[0032] Washing: add pure water to the concentrate, the amount of pure water is 70%-90% of the mass of the concentrate, mix well and let stand;

[0...

Embodiment 1

[0036] The Antarctic krill powder was extracted with 95% ethanol for 30 minutes at a solid-liquid ratio of 1:3, and extracted continuously for 3 times to obtain an extract. The extract was sequentially passed through the ion exchanger I filled with HND-8 cation exchange resin and the ion exchanger II filled with D4020 macroporous adsorption resin, the adsorption temperature was 25°C, the liquid flow rate was 15BV / h, and the working exchange capacity of the resin was 8BV. Collect the effluent. Concentrate the effluent to 15%, add pure water in an amount of 70% of the mass of the concentrated solution, mix well, let stand to separate layers, take the lower layer solution, and desolvate at 62°C and a vacuum of -0.09MPa to obtain Antarctic Phosphorus Shrimp Oil 10.35%.

Embodiment 2

[0038] The procedure is the same as in Example 1, except that in the adsorption step, the adsorption temperature is 25°C, the liquid flow rate is 9BV / h, and the working exchange capacity of the resin is 12BV. Finally, 10.64% Antarctic krill oil was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com