Device for reducing nitric oxide in coke oven flue gas through exhaust gas circulation

A technology of coke oven flue gas and nitrogen oxides, applied in incinerators, regulating fuel supply, combustion methods, etc., can solve problems such as high nitrogen oxide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

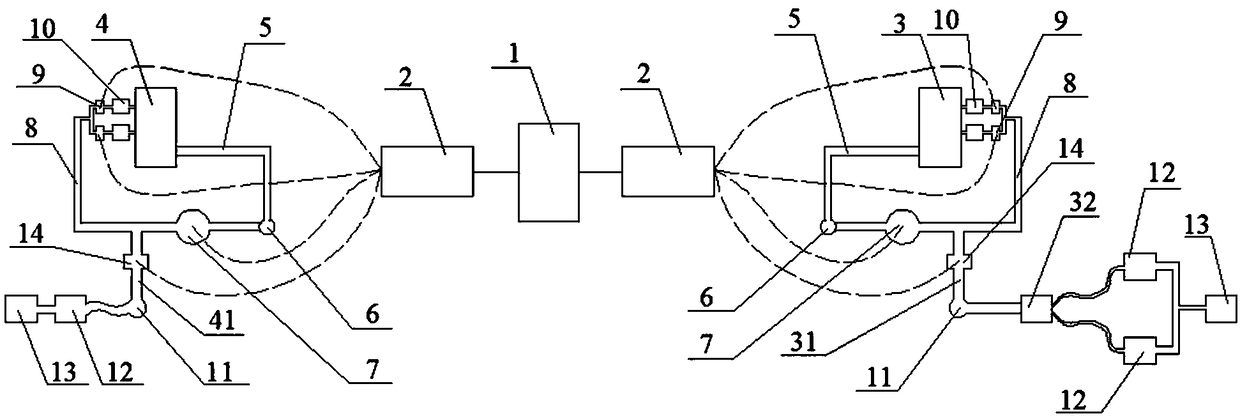

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] The invention discloses a device for reducing nitrogen oxides in coke oven flue gas through waste gas circulation, such as figure 1 As shown, it includes a PLC control board 1, and the PLC control board 1 is connected to two industrial computers 2 respectively. It is connected to the single-heating coke oven 4, and the external circulation system of the reheating coke oven is connected to the reheating coke oven 3. Each operation of the single-heating coke oven 4 or the reheating coke oven 3 can be controlled through the corresponding industrial computer 2 to realize automatic control, and the operation is simple and convenient. The PLC control board 1 and two industrial computer 2 form an automatic control system. The main control unit of the automatic control system adopts Siemens PLC (S7-300) system, and the 1 / 0 point shrinkage is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com