Method for effectively controlling diamond wire wet chemical black silicon battery piece EL poor performance

A diamond wire and wet chemical technology, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of low cell efficiency, open voltage, low short current, metal pollution, etc., achieve normal appearance and efficiency, and reduce production Cost, the effect of reducing the proportion of bad and low-efficiency tablets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

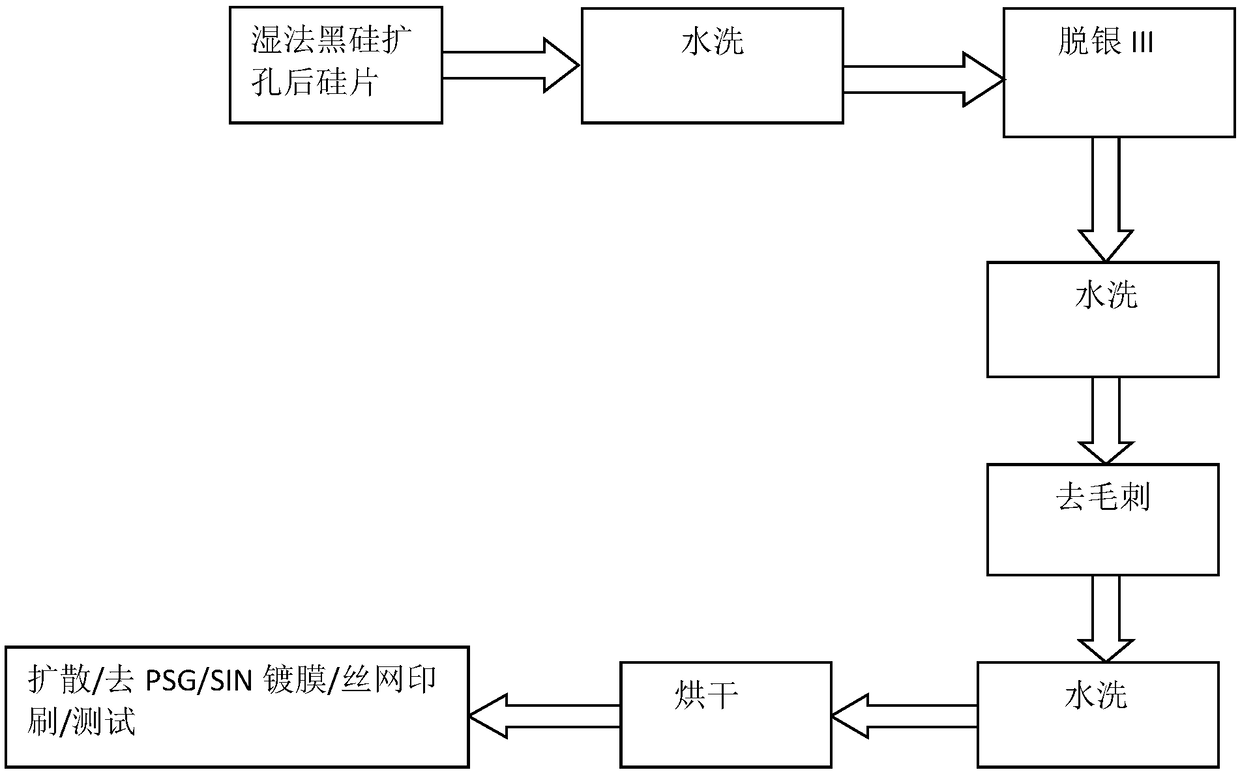

[0021] A kind of method of effectively controlling diamond wire wet chemical black silicon battery sheet EL bad (crack) of the present invention, it comprises the following steps:

[0022] 1) Texturing: After the original silicon wafer is treated by removing the damaged layer, silver deposition, digging holes, preliminary desilvering, and hole expansion, it is treated with a chemical mixed solution, which is an acidic mixed solution composed of hydrochloric acid and water , and the volume ratio in the mixed solution is hydrochloric acid: water=36:199, the concentration of the hydrochloric acid is 37%, and the weight loss of the wet-process black silicon textured silicon wafer is controlled at 0.35~0.45g;

[0023] 2) From the diffusion process of the normal production line process, it can be processed in the normal production line process.

[0024] When processing in step 1), the feed rate of cleaning machine is controlled at 270s / 480pcs (sheet); The principle of replenishment ...

Embodiment 2

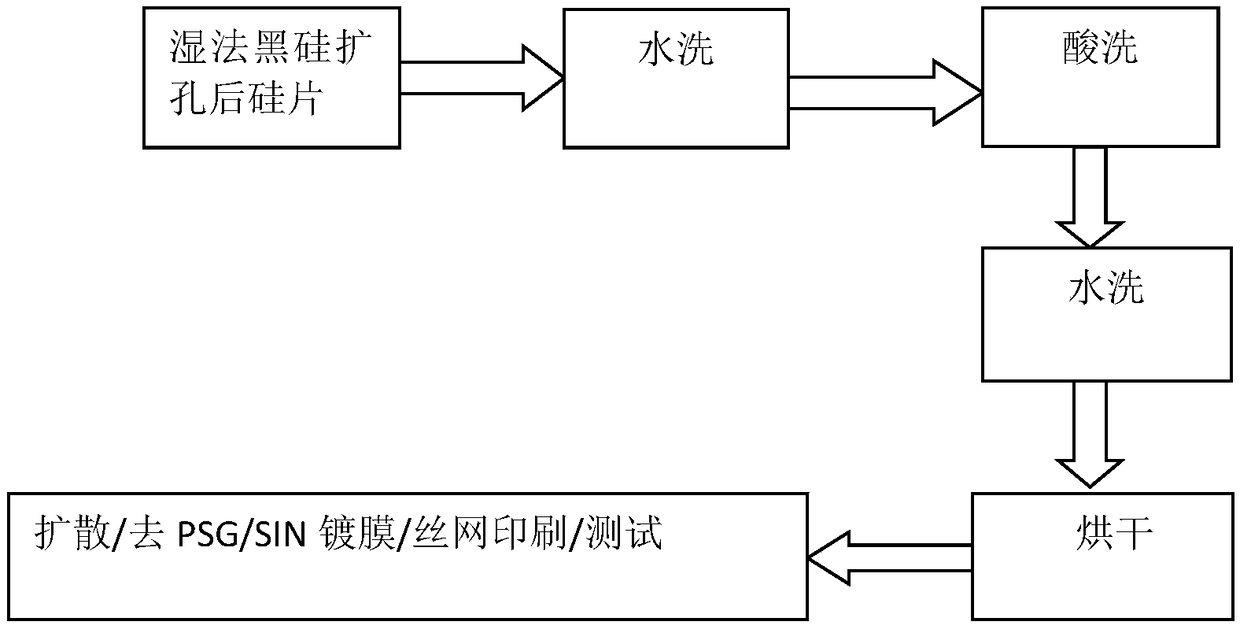

[0027] A method for effectively controlling the EL defect (crack) of the diamond wire wet chemical black silicon cell, it comprises the following steps:

[0028] 1) Texturing: After the original silicon wafer is treated by removing the damaged layer, silver deposition, digging holes, preliminary desilvering, and hole expansion, it is treated with a chemical mixed solution, which is an acidic mixed solution composed of hydrochloric acid and water , and the volume ratio in the mixed solution is hydrochloric acid: water=45:190, the concentration of the hydrochloric acid is 37%, and the weight loss of wet-process black silicon textured silicon wafers is controlled at 0.35~0.45g;

[0029] 2) From the diffusion process of the normal production line process, it can be processed in the normal production line process.

[0030] When processing in step 1), the feed rate of cleaning machine is controlled at 230s / 480pcs (sheet); The principle of replenishment of hydrochloric acid in the mi...

Embodiment 3

[0033] A method for effectively controlling the EL defect (crack) of the diamond wire wet chemical black silicon cell, it comprises the following steps:

[0034] 1) Texturing: After the original silicon wafer is treated by removing the damaged layer, silver deposition, digging holes, preliminary desilvering, and hole expansion, it is treated with a chemical mixed solution, which is an acidic mixed solution composed of hydrochloric acid and water , and the volume ratio in the mixed solution is hydrochloric acid: water=85:150, the concentration of the hydrochloric acid is 37%, and the weight loss of the wet-process black silicon textured silicon wafer is controlled at 0.35~0.45g;

[0035] 2) From the diffusion process of the normal production line process, it can be processed in the normal production line process.

[0036] When processing in step 1), the feed rate of cleaning machine is controlled at 215s / 480pcs (sheet); The principle of replenishment of hydrochloric acid in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com