High temperature-resistant flexible elastic sealing gasket and preparation method and application of high temperature-resistant flexible elastic sealing gasket

A technology of gaskets and refractory fibers, applied in textiles and papermaking, non-polymer adhesive additives, epoxy resin adhesives, etc., can solve the problems of easy powdering of sealing materials, poor sealing effect and low mechanical strength, etc. Achieve the effect of improving sealing performance, excellent corrosion resistance and overall performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Prepare the gasket as follows:

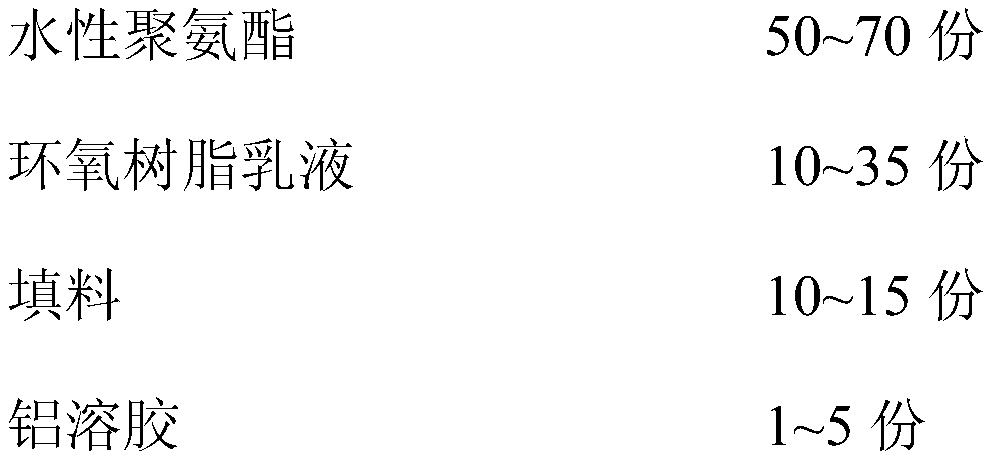

[0070] In this embodiment, the components and proportions of the binder slurry for the gasket are selected as follows: 52 parts of water-based polyurethane, 30 parts of epoxy resin emulsion, 13 parts of filler, 5 parts of aluminum sol, and 0.8 parts of dispersing agent.

[0071] (1) Add water-based polyurethane, epoxy resin emulsion, aluminum sol and dispersant to a high-speed mixer and stir for 20 minutes. After mixing well, add 13 parts of filler. The composition of the filler is that vermiculite particles and short mullite fibers are added in a mass ratio of 1:1. A stable binder slurry was formed after ball milling for 1 h. The dispersant is sodium dodecylbenzenesulfonate.

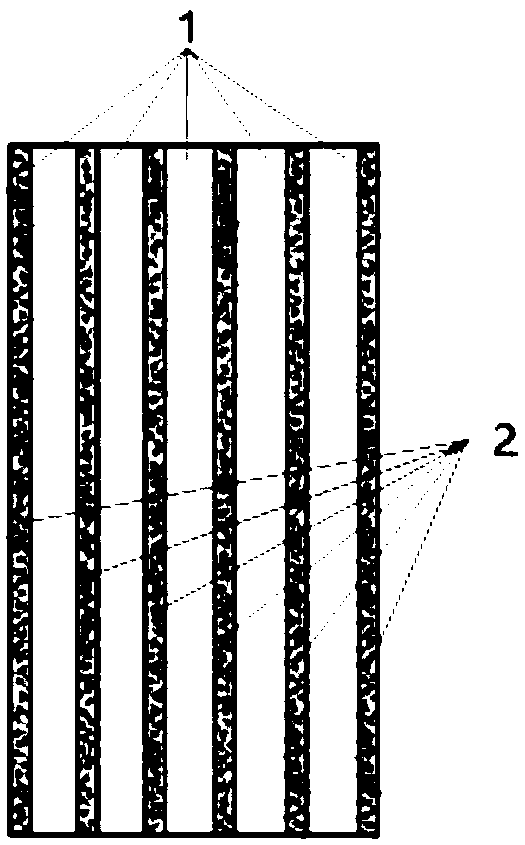

[0072] (2) Use plain high-silica fiber cloth with a purity higher than 96% as the substrate, and after pretreatment at 600°C for 30 minutes, use an automatic rubber rolling machine to evenly coat the binder slurry on the upper and lower sides of the fiber cloth...

Embodiment 2

[0079] Prepare the high temperature resistant flexible elastic gasket according to the following steps:

[0080] The binder slurry components and proportions of the sealing material in this embodiment are selected as follows: 68 parts of water-based polyurethane, 16 parts of epoxy resin emulsion, 15 parts of filler, 1 part of aluminum sol, and 1 part of dispersant .

[0081] (1) Add water-based polyurethane, epoxy resin emulsion, aluminum sol and dispersant to a high-speed mixer and stir for 20 minutes. After mixing evenly, add 15 parts of filler. The filler is composed of vermiculite particles, mullite short fibers and zirconia short fibers in a mass ratio of 2:1:1. A stable binder slurry is formed after stirring. The stirring speed was controlled at 800 rpm, and stirred for 50 min. The dispersant is sodium alkyl diphenyl ether monosulfonate.

[0082] (2) Use a satin-surface high-silica fiber cloth with a purity higher than 96% as the substrate, and after ultrasonic vibra...

Embodiment 3

[0087] Prepare the high temperature resistant flexible elastic gasket according to the following steps:

[0088] In this embodiment, the binder slurry components and proportions of the high-temperature gasket are selected as follows: 65 parts of water-based polyurethane, 22 parts of epoxy resin emulsion, 10 parts of filler, 3 parts of aluminum sol, and 0.5 parts of dispersing agent.

[0089] (1) Add water-based polyurethane, epoxy resin emulsion, aluminum sol and dispersant to a high-speed mixer and stir for 50 minutes. After stirring evenly, add 10 parts of filler. The composition of the filler is that vermiculite particles and short mullite fibers are added in a mass ratio of 2:1. After mixing, a stable binder slurry is formed. The dispersant is sodium dodecylbenzenesulfonate.

[0090] (2) Use stainless steel wire-reinforced plain aluminum silicate fiber cloth as the substrate, impregnate the fiber cloth in the above slurry, stack three layers, and dry at 60°C for 5 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com