A method for enriching platinum from the oxidative leaching precipitate of silicon-alumina-based platinum-containing spent catalyst

A waste catalyst and sediment technology, applied in the direction of improving process efficiency, can solve the problems of high resin breakage rate, high recovery cost, resin blockage, etc., and achieve the effects of easy filtration and separation, improving recovery rate and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

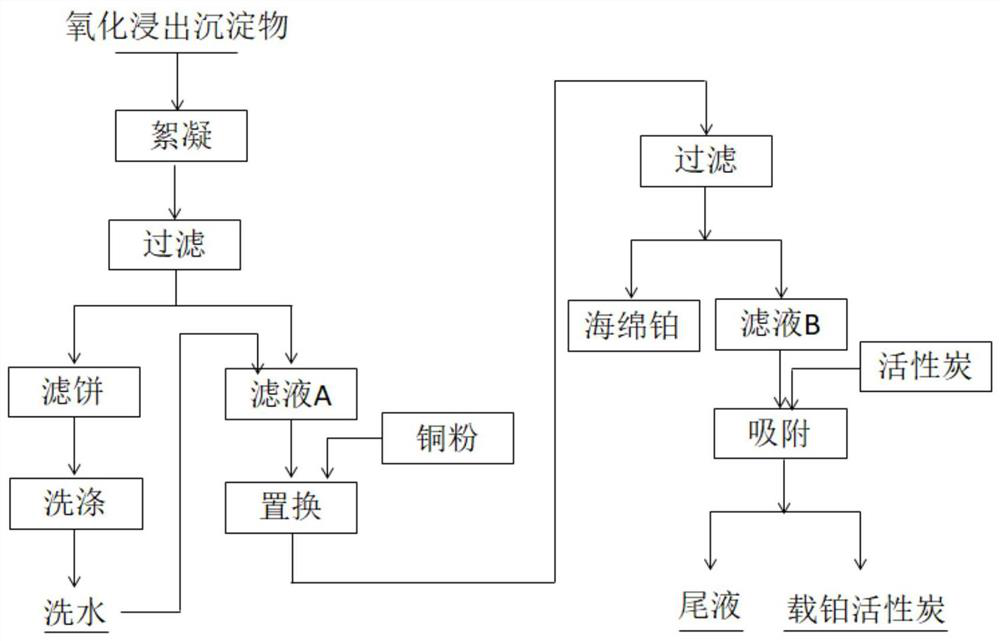

[0018] A method for enriching platinum from the oxidative leaching precipitate of a silicon-alumina-based platinum-containing spent catalyst, such as figure 1 shown, including the following steps:

[0019] (1) Flocculation and sedimentation: slowly add mass to 4000ml oxidation leaching precipitate (solid content is 3%, platinum concentration is 100mg / L, silicon concentration is 200mg / L, hydrogen ion concentration is 0.3mol / L) under stirring state Concentration is 200ml of flocculant solution of 0.1%, leave standstill 15min, filter, and the gained filter cake is washed repeatedly with water, and the adding amount of each washing water is 2 times of filter cake quality, measures the platinum concentration in the washing water after each washing, until Stop washing if the platinum content in the washing water is less than 0.5mg / L;

[0020] (2) Metal replacement: Filtrate A and washing water are collected and merged, the pH of the solution is adjusted to 0.5, and the volume of th...

Embodiment 2

[0023] A method for enriching platinum from the oxidative leaching precipitate of a silicon-alumina-based platinum-containing spent catalyst, such as figure 1 shown, including the following steps:

[0024] (1) Flocculation and sedimentation: Slowly add mass to 4500ml oxidation leaching precipitate (solid content is 3%, platinum concentration is 100mg / L, silicon concentration is 200mg / L, hydrogen ion concentration is 0.3mol / L) under stirring state Concentration is 150ml of flocculant solution of 0.1%, leave standstill 10min, filter, and the gained filter cake is washed repeatedly with water, and the amount of adding water for each washing is 2 times of the filter cake quality, measures the platinum concentration in the washing water after each washing, until Stop washing if the platinum content in the washing water is less than 0.5mg / L;

[0025] (2) Metal replacement: Filtrate A and washing water are collected and merged, the pH of the solution is adjusted to 0.5, and the volu...

Embodiment 3

[0028] A method for enriching platinum from the oxidative leaching precipitate of a silicon-alumina-based platinum-containing spent catalyst, such as figure 1 shown, including the following steps:

[0029] (1) Flocculation and sedimentation: slowly add mass to 4000ml oxidation leaching precipitate (solid content is 3%, platinum concentration is 100mg / L, silicon concentration is 200mg / L, hydrogen ion concentration is 0.3mol / L) under stirring state Concentration is 100ml of flocculant solution of 0.1%, leave standstill 10min, filter, and the gained filter cake is washed with water several times, and the amount of adding water for each washing is 2 times of the filter cake quality, measures the platinum concentration in the washing water after each washing, until Stop washing if the platinum content in the washing water is less than 0.5mg / L;

[0030] (2) Metal replacement: Filtrate A and washing water are collected and merged, the pH of the solution is adjusted to 1, and the vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com