Three-dimensional nano-iron oxide, its gel in-situ preparation method and its application

A three-dimensional nano, iron oxide technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, iron oxides, etc., can solve the problems of difficult solid-liquid separation, easy agglomeration of powder products, etc. Liquid separation, excellent adsorption performance and catalytic performance, shape controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Specifically, the preparation method of the three-dimensional nano-iron oxide of the present invention comprises the following steps:

[0021] Step 1, dissolving a water-soluble polymer, preferably polyvinyl alcohol, gelatin, agar, etc., more preferably polyvinyl alcohol, and iron salt in water to obtain a mixed solution;

[0022] Step 2, heating the mixed solution obtained in step 1 to obtain ordered and graded nano-iron oxides grown in situ by water-soluble polymer templates;

[0023] In step 3, the product obtained in step 2 is repeatedly frozen and thawed to obtain a three-dimensional nano-iron oxide composite gel grown in situ with a water-soluble polymer template.

[0024] In the above preparation method, the concentrations of the water-soluble polymer and the iron salt in step 1 are respectively 5-200 mg / mL and 0.01-200 mol / mL, preferably 100 mg / mL and 0.1 mol / L.

[0025] In the above preparation method, the iron salt in step 1 is a soluble ferrous salt, such as...

Embodiment 1

[0032] In this example, the double network gel is prepared by one-step green method, and the specific preparation steps are as follows:

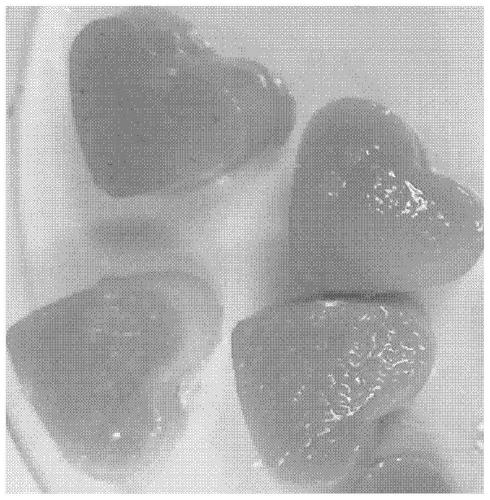

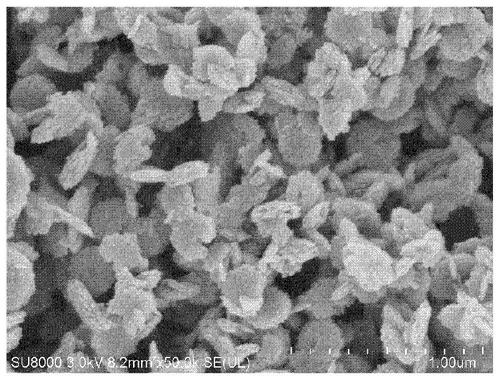

[0033] Prepare a mixed solution of polyvinyl alcohol and ferrous sulfate. The concentration of polyvinyl alcohol in the mixed solution is 100 mg / mL, and the molar concentration of ferrous sulfate is 0.1 mol / L. Stir to form a uniform solution. Put the mixed solution into a polytetrafluoroethylene-lined stainless steel reaction kettle, heat it at 120°C for 12h, put the heated product into a mold, put it in a refrigerator and freeze it at -40°C for 12h, take it out and thaw it to room temperature, After repeated freezing-thawing three times, the three-dimensional nano-iron oxide grown in situ and fixed in gel can be obtained. The adsorption or catalytic degradation efficiency of the product for tetracycline with an initial concentration of 100 mg / mL in water can be higher than 99%. The optical photograph of the product is as figure 1 As shown...

Embodiment 2

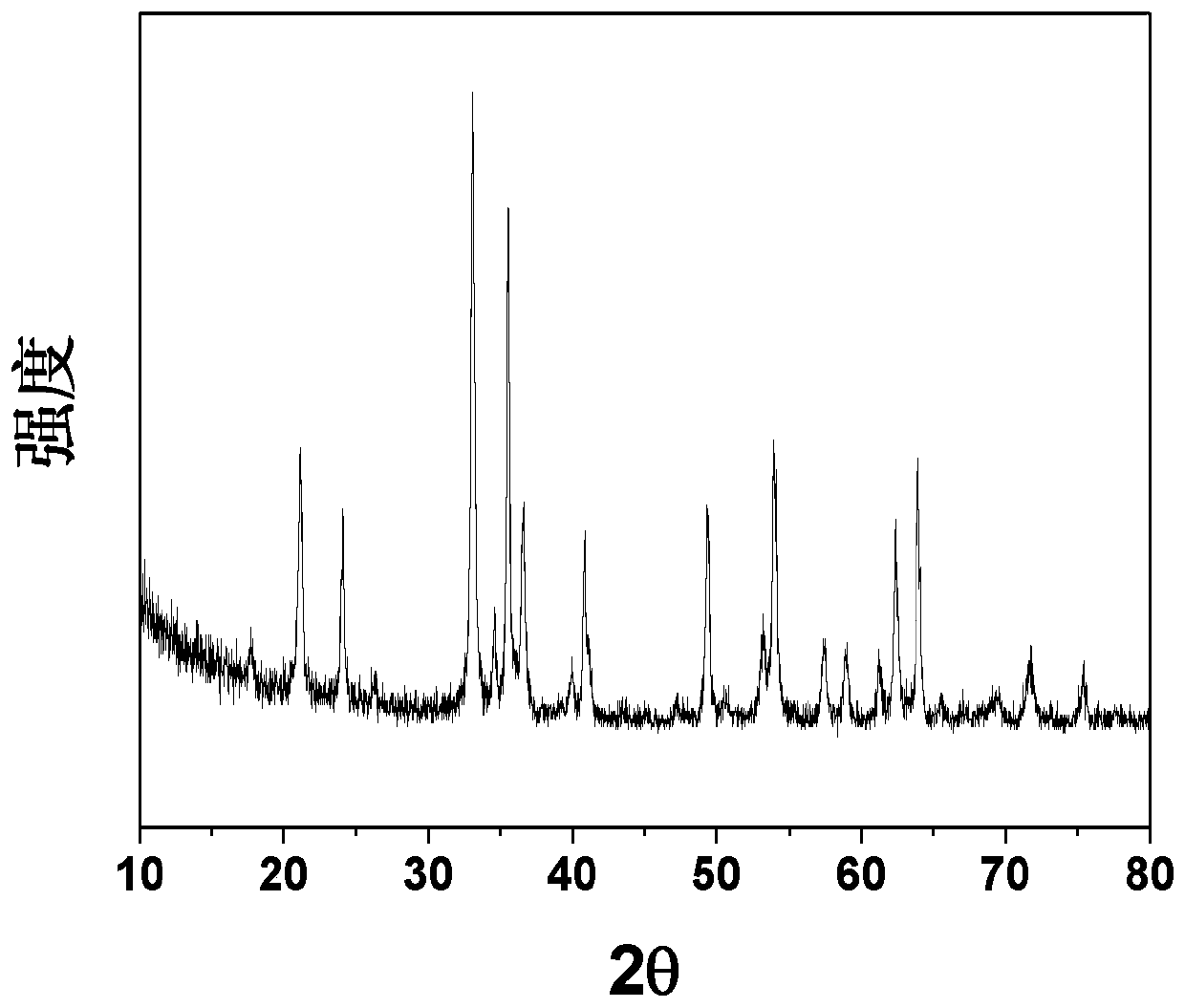

[0035] Prepare a mixed solution of polyvinyl alcohol and ferrous sulfate. The concentration of polyvinyl alcohol in the mixed solution is 200 mg / mL, and the molar concentration of ferrous sulfate is 0.1 mol / L. Stir to form a uniform solution. Put the mixed solution into a polytetrafluoroethylene-lined stainless steel reaction kettle, heat it at 180°C for 12h, put the heated product into a mold, put it in a refrigerator and freeze it at -40°C for 12h, take it out and thaw it to room temperature, After repeated freezing-thawing three times, the three-dimensional nano-iron oxide grown in situ and fixed in gel can be obtained. According to XRD analysis, the type of iron oxide formed is α-Fe 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com